In short, PTFE is an ideal material for the food, dairy, and pharmaceutical industries because it is chemically inert, non-toxic, and FDA-approved for direct contact with consumables. Its exceptionally non-stick and durable surface also ensures it can be easily and thoroughly sanitized, preventing contamination and upholding the strictest hygiene standards.

The core challenge in food, pharma, and dairy processing is the absolute prevention of product contamination. PTFE is the material of choice not for a single reason, but for its unique combination of properties—chemical inertness, surface slickness, and durability—that work in concert to guarantee product purity and operational hygiene.

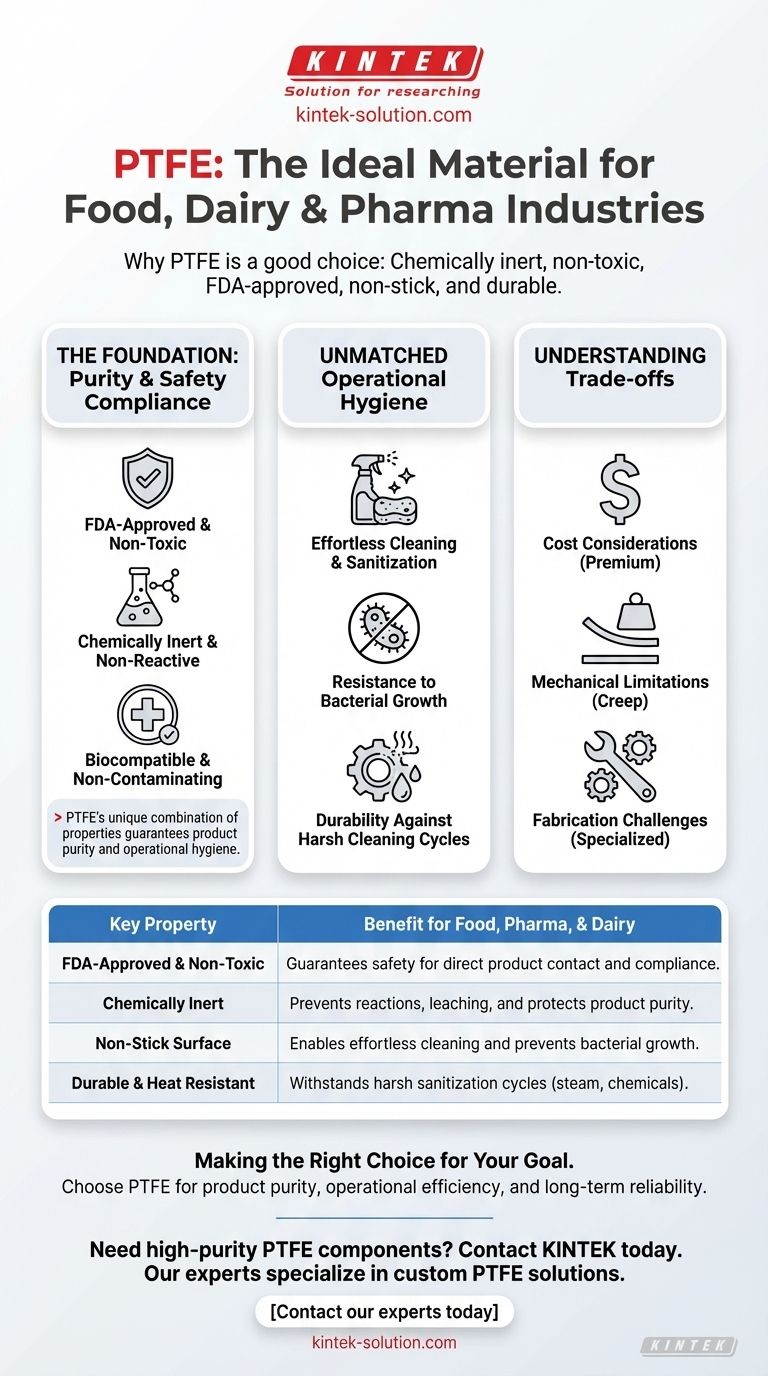

The Foundation: Purity and Safety Compliance

For any material to be considered in these regulated environments, it must first meet a baseline of absolute safety. PTFE exceeds this baseline by its very nature.

FDA-Approved and Non-Toxic

The most critical factor is that specific grades of PTFE are FDA-approved. This certification confirms the material is non-toxic and safe for direct contact with food, beverages, and pharmaceutical products, making it a compliant and defensible choice.

Chemically Inert and Non-Reactive

PTFE is one of the most chemically inert materials known. It will not react with, leach into, or degrade when exposed to the vast majority of chemicals, active pharmaceutical ingredients (APIs), or food products. This ensures the final product's purity, taste, and efficacy are never compromised.

Biocompatible and Non-Contaminating

In medical and pharmaceutical applications, biocompatibility is essential. PTFE does not cause adverse reactions when used in processing equipment or even medical implants. Its non-contaminating nature guarantees that nothing from the material itself transfers to the product it touches.

Unmatched Operational Hygiene

Beyond passive safety, a material must support the active processes that maintain a sterile environment. PTFE's physical properties make it superior for day-to-day plant operations.

Effortless Cleaning and Sanitization

PTFE is famous for its non-stick surface. This property prevents food, dairy, or drug residues from adhering to equipment like seals, bellows, and expansion joints. The result is faster, more effective, and more reliable cleaning cycles.

Resistance to Bacterial Growth

The material's smooth, non-porous surface provides no microscopic crevices for bacteria to colonize. This inherent resistance to bacterial growth is a fundamental advantage in maintaining a hygienic processing line.

Durability Against Harsh Cleaning Cycles

These industries rely on aggressive sanitization, including high-pressure steam, strong acids, and caustic cleaning agents. PTFE demonstrates excellent thermal stability and chemical resistance, allowing it to withstand these harsh cleaning regimens without degrading over time.

Understanding the Trade-offs

While PTFE is an exceptional material, a complete technical assessment requires acknowledging its limitations. No material is perfect for every single application.

Cost Considerations

PTFE is a premium performance polymer, and its cost is generally higher than that of commodity plastics or some elastomers. The investment is justified by its safety, longevity, and reduced maintenance, but the initial capital outlay is a factor.

Mechanical Limitations

Compared to metals or other engineering plastics, PTFE is relatively soft and has lower tensile strength. It can be susceptible to "creep"—a slow deformation under sustained load—and may not be suitable for high-load structural components without reinforcement.

Fabrication Challenges

The same properties that make PTFE chemically inert and non-stick can also make it more difficult to bond or machine than other materials. Proper fabrication requires specialized knowledge and equipment to achieve precise results.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on prioritizing the uncompromising demands of your industry.

- If your primary focus is product purity and safety: PTFE's chemical inertness and FDA-approved status provide an unmatched guarantee against contamination.

- If your primary focus is operational efficiency and hygiene: The non-stick surface dramatically simplifies cleaning protocols, reducing downtime and ensuring a more sterile environment.

- If your primary focus is long-term reliability in harsh environments: PTFE's resistance to aggressive cleaning chemicals and high temperatures ensures a longer service life for components.

Ultimately, choosing PTFE for these critical applications is a decision rooted in risk mitigation and quality assurance.

Summary Table:

| Key Property | Benefit for Food, Pharma, & Dairy |

|---|---|

| FDA-Approved & Non-Toxic | Guarantees safety for direct product contact and compliance. |

| Chemically Inert | Prevents reactions, leaching, and protects product purity. |

| Non-Stick Surface | Enables effortless cleaning and prevents bacterial growth. |

| Durable & Heat Resistant | Withstands harsh sanitization cycles (steam, chemicals). |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get components that guarantee product purity, meet strict compliance standards, and enhance operational efficiency.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key physical properties of PTFE? Unlock Its Extreme Performance for Demanding Applications

- What are the characteristics of PFA material? A Guide to Its High-Performance Balance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the monomer used in the preparation of PTFE? Mastering the Synthesis of Tetrafluoroethylene

- What are some common uses of PTFE laminated fabrics? Essential for Waterproof, Breathable Performance Gear

- Is Teflon used in medical applications? Leverage Its Biocompatibility and Low Friction

- What is the difference between virgin PTFE and filled PTFE? Choose the Right Material for Your Application

- Why is PTFE suitable for solar panel manufacturing? Unmatched Durability for 25+ Year Lifespan