In short, PTFE laminated fabrics are primarily used in high-performance applications where waterproofness and breathability are both critical. This unique combination makes them essential for advanced outdoor gear like mountaineering suits and tents, protective military and medical clothing, and even specialized uses like space suits.

The core value of a PTFE laminate is not the fabric itself, but a microscopic PTFE membrane bonded to it. This membrane has pores small enough to block liquid water but large enough to let water vapor (sweat) escape, solving the fundamental challenge of staying dry from both the outside and the inside.

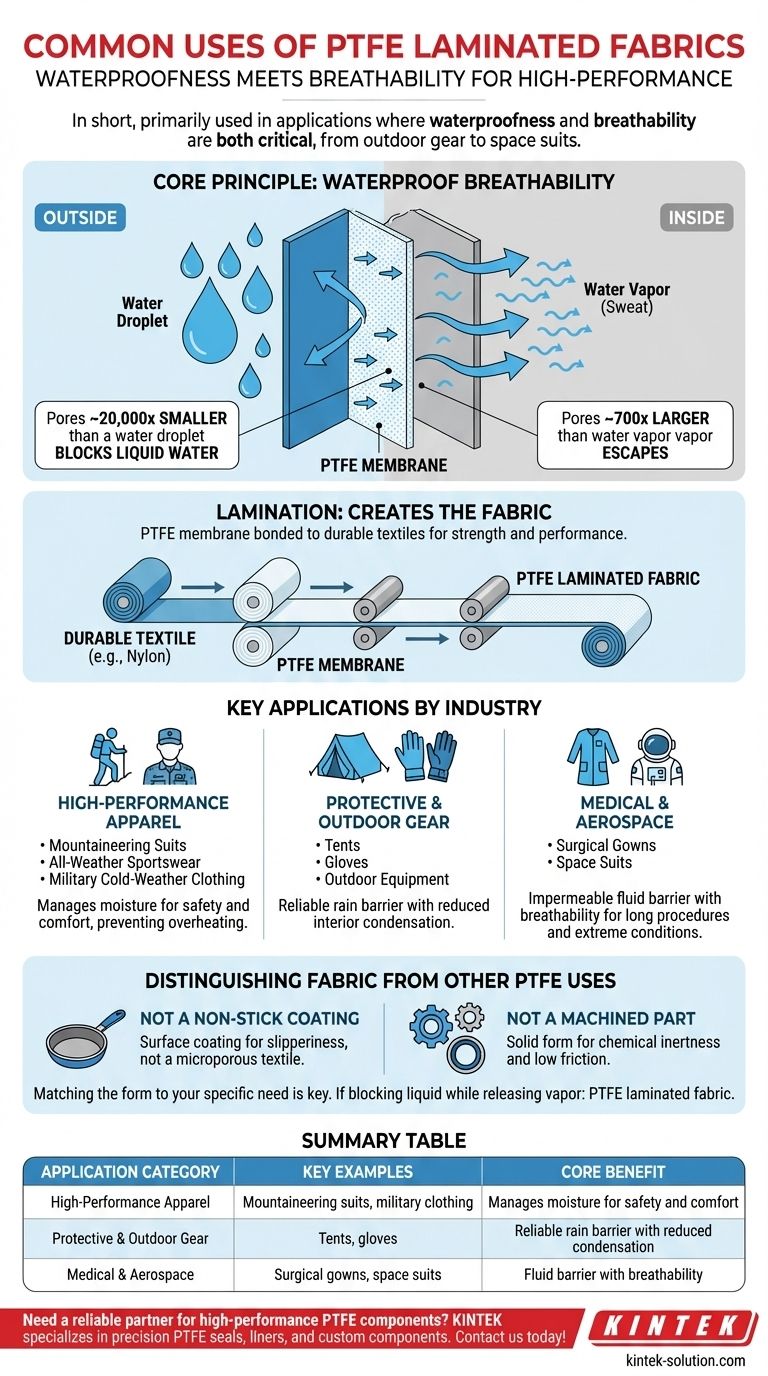

The Core Principle: Waterproof Breathability

The reason PTFE laminated fabrics are used in such demanding environments comes down to a single, elegant piece of material science.

How the PTFE Membrane Works

The heart of the material is an extremely thin layer of expanded Polytetrafluoroethylene (PTFE). This membrane is stretched to create a microporous structure with billions of pores per square inch.

These pores are approximately 20,000 times smaller than a water droplet, making it impossible for rain or snow to penetrate.

Simultaneously, these same pores are about 700 times larger than a water vapor molecule. This allows perspiration to escape, preventing the clammy, wet feeling that occurs when moisture is trapped inside a garment.

Lamination Creates the Fabric

On its own, this PTFE membrane is too fragile for practical use. To create a functional material, it is bonded, or laminated, to durable textiles like nylon or polyester.

This process combines the waterproof-breathable properties of the PTFE membrane with the strength, texture, and durability of a traditional fabric.

Key Applications by Industry

The unique properties of PTFE laminates make them the material of choice in fields where performance is non-negotiable.

High-Performance Apparel

This is the most common and recognizable use. Applications include mountaineering suits, all-weather sportswear, and military extreme cold-weather clothing.

In these contexts, managing moisture is critical for safety and comfort. Staying dry prevents hypothermia, and allowing sweat to evaporate keeps the wearer from overheating during intense activity.

Protective and Outdoor Gear

The technology extends to equipment like tents and gloves. A PTFE laminate in a tent provides a reliable barrier against rain while reducing interior condensation.

In gloves, it provides a waterproof layer that doesn't trap sweat, keeping hands warmer and more comfortable in harsh conditions.

Medical and Aerospace

In medicine, PTFE laminates are used for surgical gowns. They provide an impermeable barrier to blood and other fluids, protecting healthcare workers, while still offering enough breathability for comfort during long procedures.

The most extreme application is in space suits, where the layers must protect against the vacuum of space while managing the astronaut's body temperature and moisture.

Distinguishing Fabric from Other PTFE Uses

It is crucial to understand that "PTFE laminated fabric" is a very specific product. The broader material, PTFE, is used in many other forms that leverage different properties.

Not a Non-Stick Coating

While PTFE is famous for its use as a non-stick coating on cookware, this application leverages its low coefficient of friction (its "slipperiness"). This is a surface coating, not a microporous, laminated textile.

Not a Machined Part

PTFE is also widely used in solid forms like bushings, seals, and expansion joints for industrial machinery, automotive parts, and chemical plants.

These applications rely on PTFE's chemical inertness and low-friction properties in a solid, structural form. This is entirely different from the breathable membrane technology used in fabrics.

Making the Right Choice for Your Goal

Understanding the different forms of PTFE allows you to select the correct material for your specific technical challenge.

- If your primary focus is blocking liquid while releasing vapor: A PTFE laminated fabric is the industry standard for high-performance waterproof-breathable gear.

- If your primary focus is extreme chemical resistance or low friction in a solid part: You should be looking at machined or molded PTFE components.

- If your primary focus is creating an easy-release surface: A direct PTFE coating is the technology designed for that purpose.

Ultimately, matching the form of this versatile polymer to your specific need is the key to successful engineering and design.

Summary Table:

| Application Category | Key Examples | Core Benefit |

|---|---|---|

| High-Performance Apparel | Mountaineering suits, military clothing | Manages moisture for safety and comfort |

| Protective & Outdoor Gear | Tents, gloves | Reliable rain barrier with reduced condensation |

| Medical & Aerospace | Surgical gowns, space suits | Fluid barrier with breathability for long procedures |

Need a reliable partner for high-performance PTFE components? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your materials meet the highest standards of durability and performance. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main material characteristics of PTFE? Unlock Superior Performance in Extreme Environments

- What are the benefits of glass-filled PTFE? Achieve Superior Strength & Wear Resistance

- Is PTFE a thermoplastic or thermoset material? Unpacking Its Unique Polymer Properties

- What physical forms is PTFE available in? From Raw Powders to Custom Components

- How was PTFE accidentally discovered? The Serendipitous Story of Teflon's Invention

- What are the limitations of traditional PTFE? Overcome Creep and Porosity with Modified PTFE

- What are some key properties of Teflon that make it widely useful? Discover Its Unique Advantages

- What industries commonly use ePTFE? Discover Where This High-Performance Material Excels