While known for its extreme chemical resistance and low friction, traditional Polytetrafluoroethylene (PTFE) is defined as much by its limitations as its strengths. Its primary weaknesses are poor creep resistance (deformation under load), difficulty in welding, and high microporosity, which are addressed through two main strategies: chemical modification with comonomers and physical reinforcement with fillers.

The core challenge with PTFE is that its exceptional chemical inertness comes at the cost of mechanical weakness. The solution is not to abandon the material, but to select a modified or filled grade that specifically compensates for the mechanical or processing deficiencies of its virgin form.

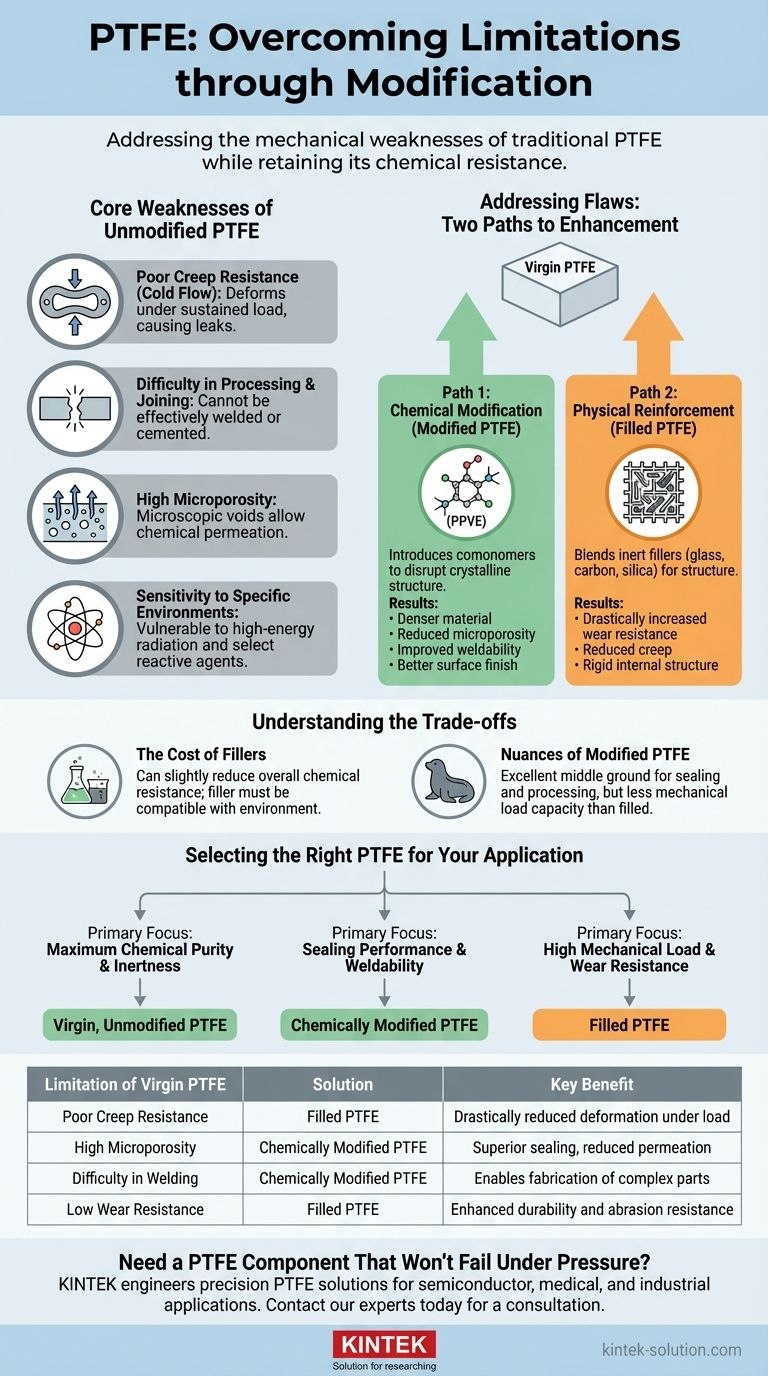

The Core Weaknesses of Unmodified PTFE

To choose the right material, you must first understand the specific failure points of standard, or "virgin," PTFE. These limitations are not chemical but almost entirely mechanical and structural.

Poor Creep Resistance (Cold Flow)

Unmodified PTFE lacks sturdiness. When subjected to sustained pressure, especially at elevated temperatures, it will deform over time in a process known as creep or cold flow.

This is a critical failure point for components like gaskets and seals, where constant pressure is required to maintain a seal. Over time, the material flows away from the pressure point, leading to a loss of sealing force and eventual leaks.

Difficulty in Processing and Joining

The same properties that make PTFE non-stick also make it extremely difficult to join. Standard PTFE cannot be effectively welded or cemented.

This complicates the manufacturing of complex parts, often requiring them to be machined from a solid block of material, which can be inefficient and costly for mass production.

High Microporosity

The process used to create standard PTFE results in a molecular structure with microscopic voids. This microporosity can be a significant problem in applications requiring gas or liquid sealing.

Aggressive chemicals can permeate these voids, potentially leading to contamination or premature failure of the component.

Sensitivity to Specific Environments

While famously inert, PTFE is not invincible. It has poor resistance to high-energy radiation, which can break down its molecular structure.

It can also be attacked by a small number of extremely reactive chemical agents, such as elemental fluorine or chlorine trifluoride, particularly under high pressure and temperature.

Addressing the Flaws: Two Paths to Enhancement

Engineers have developed two primary methods to overcome the inherent weaknesses of virgin PTFE, creating materials suitable for a much wider range of demanding applications.

Path 1: Chemical Modification (Modified PTFE)

This approach alters the fundamental chemistry of the polymer. By introducing a small amount of a comonomer—most commonly Perfluoropropyl Vinyl Ether (PPVE)—the crystalline structure of the PTFE is disrupted.

This results in a denser, less porous material. This "modified PTFE" (sometimes called TFM) offers significantly reduced microporosity, improved weldability, and a smoother surface finish while retaining nearly all the chemical resistance of virgin PTFE.

Path 2: Physical Reinforcement (Filled PTFE)

This method is analogous to adding rebar to concrete. Inert fillers are blended into the PTFE to enhance its physical properties.

Common fillers include glass fibers, carbon, silica, or barium sulfate. These materials drastically increase wear resistance and, most importantly, reduce creep by providing a rigid internal structure.

Understanding the Trade-offs

Choosing a modified or filled PTFE is not without compromise. Enhancing one property can sometimes come at the expense of another, and this is the central trade-off you must evaluate.

The Cost of Fillers

While fillers provide immense mechanical benefits, they can slightly reduce the overall chemical resistance of the composite material.

The filler material itself may be susceptible to chemical attack even if the surrounding PTFE is not. For example, a glass-filled PTFE would be a poor choice for service with hydrofluoric acid, which attacks glass. The filler must be as resistant as possible to the intended service environment.

The Nuances of Modified PTFE

Chemically modified PTFE is an excellent middle ground. It improves processability and reduces porosity, but it does not provide the same dramatic increase in creep resistance or wear performance as a filled grade.

It is a superior sealing material but is not a direct substitute for a filled PTFE in a high-load mechanical application.

Increased Cost and Complexity

Both chemical modification and the addition of fillers add steps to the manufacturing process. This invariably increases the material's cost compared to virgin PTFE and requires more careful specification during procurement.

Selecting the Right PTFE for Your Application

Your choice must be driven by the primary demand of your application—be it chemical purity, sealing integrity, or mechanical strength.

- If your primary focus is maximum chemical purity and inertness: Virgin, unmodified PTFE is the correct choice, but you must design the application to minimize mechanical stress on the part.

- If your primary focus is sealing performance and weldability: Chemically modified PTFE is superior, offering a less porous structure that prevents permeation and enables the fabrication of more complex parts.

- If your primary focus is high mechanical load and wear resistance: Filled PTFE is the only viable option, as it is specifically engineered to resist creep and abrasion.

By understanding these distinctions, you can select a PTFE formulation that delivers not just on chemical resistance, but on the mechanical integrity your application demands.

Summary Table:

| Limitation of Virgin PTFE | Solution | Key Benefit |

|---|---|---|

| Poor Creep Resistance (Cold Flow) | Filled PTFE (e.g., glass, carbon) | Drastically reduced deformation under sustained load |

| High Microporosity | Chemically Modified PTFE (e.g., with PPVE) | Superior sealing, reduced permeation |

| Difficulty in Welding/J oining | Chemically Modified PTFE | Enables fabrication of complex parts |

| Low Wear Resistance | Filled PTFE | Enhanced durability and abrasion resistance |

Need a PTFE Component That Won't Fail Under Pressure?

Your application demands more than just chemical resistance. It requires mechanical integrity. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—that are engineered to perform.

We help semiconductor, medical, and industrial clients solve their toughest challenges by selecting or custom-formulating the right PTFE grade (virgin, modified, or filled) for your specific needs, whether you require a prototype or a high-volume order.

Let's engineer a solution that lasts. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial applications utilize expanded PTFE? Sealing, Filtration & Insulation Solutions

- What are the advantages of expanded PTFE (ePTFE)? Unlock Superior Sealing and Flexibility

- What is Teflon and what are its key properties? A Guide to its Extreme Chemical and Temperature Resistance

- What are the four basic types of Teflon and their key differences? Select the Right Fluoropolymer for Your Application

- What are the hydrophobic properties of PTFE? The Science of Permanent Water Repellency

- Why is Teflon used in high-performance applications? Unmatched Low Friction & Chemical Resistance

- What are the advantages of using Teflon over other polymers? Unmatched Performance in Extreme Conditions

- What are the industrial applications of PTFE? Unlock High-Performance in Extreme Environments