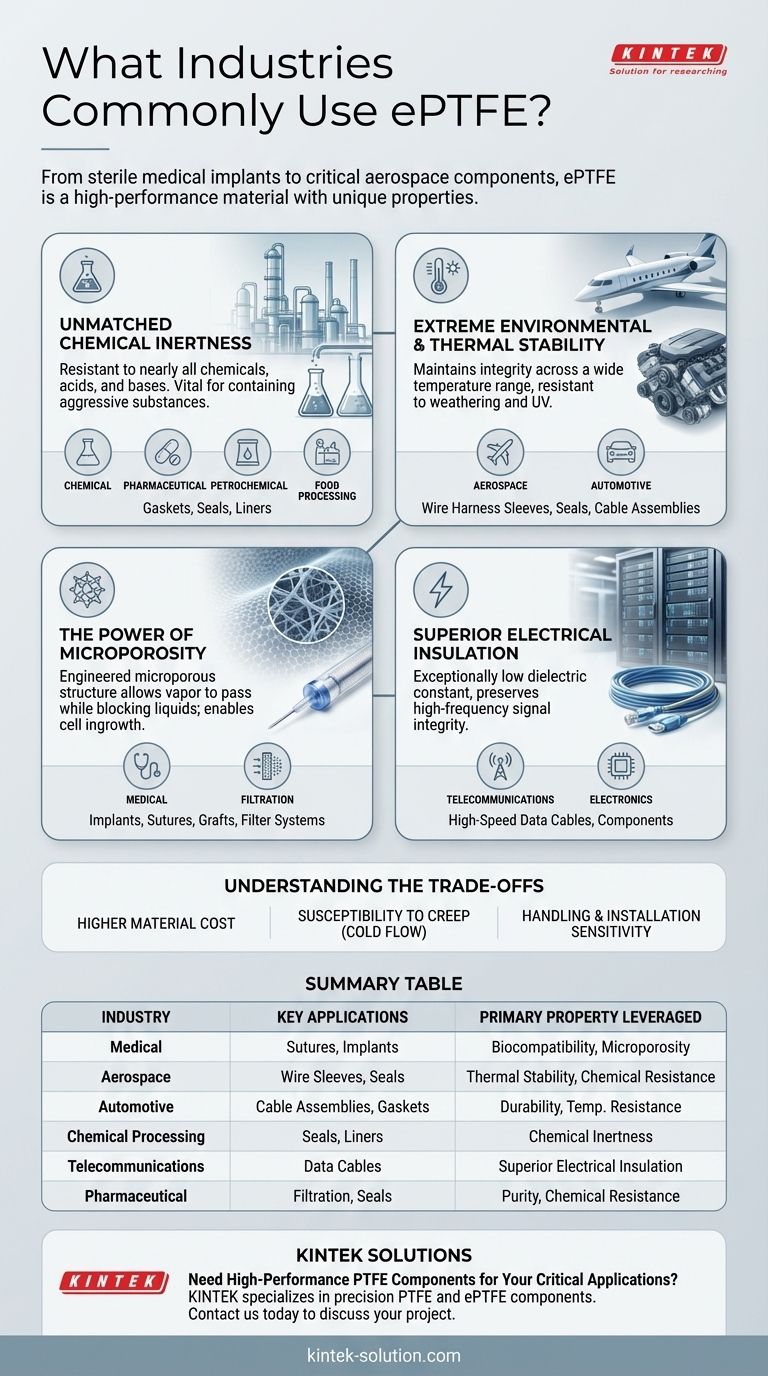

From sterile medical implants to critical aerospace components, expanded Polytetrafluoroethylene (ePTFE) is a high-performance material used across a vast range of demanding industries. Its applications are most common in the medical, aerospace, automotive, telecommunications, chemical processing, and pharmaceutical sectors due to its unique combination of properties.

The core reason for ePTFE's widespread industrial use is not a single benefit, but its rare ability to combine near-total chemical inertness, extreme temperature resistance, and a highly versatile microporous structure into one material.

Why ePTFE Is a Go-To Problem Solver

The value of ePTFE lies in its ability to perform reliably where other materials fail. Different industries leverage specific properties to solve their most critical challenges.

Unmatched Chemical Inertness

ePTFE is resistant to nearly all chemicals, acids, and bases. This makes it an essential material for containing and processing aggressive substances safely.

This property is critical in the chemical, pharmaceutical, petrochemical, and food processing industries. It is commonly used for gaskets, seals, and liners in environments where material degradation would lead to contamination or catastrophic failure.

Extreme Environmental and Thermal Stability

The material maintains its integrity across a very wide temperature range and is highly resistant to weathering and UV degradation.

This durability makes it vital for aerospace and automotive applications. You will find ePTFE used in wire harness sleeves, cable assemblies, and seals that must withstand extreme temperatures, vibration, and exposure to fuels and fluids.

The Power of Microporosity

The "expanded" nature of ePTFE creates a microscopic, web-like structure. This structure can be engineered to allow vapor to pass through while blocking liquids.

This unique feature is the basis for its use in high-performance filtration systems and waterproof, breathable fabrics. In the medical field, this porosity allows for cell ingrowth, making ePTFE a premier material for sutures, vascular grafts, and dental implants.

Superior Electrical Insulation

ePTFE has an exceptionally low dielectric constant, which means it does not interfere with high-frequency electrical signals.

This makes it a top-tier insulator for the telecommunications and electronics industries. It is used in high-speed data cables and other critical electronic components where preserving signal integrity is paramount.

Understanding the Trade-offs

While ePTFE is a superior material, it's essential to understand its limitations to apply it correctly. Objectivity requires acknowledging where it may not be the best fit.

Higher Material Cost

ePTFE is a premium, high-performance polymer. Its manufacturing process is complex, making it significantly more expensive than commodity plastics or standard elastomers.

Susceptibility to Creep (Cold Flow)

Like all fluoropolymers, ePTFE can be subject to "creep" or "cold flow," meaning it can slowly deform over time when subjected to a constant load, especially at elevated temperatures.

This must be accounted for in engineering design, particularly for high-pressure gasket applications, to ensure a long-lasting and reliable seal.

Handling and Installation Sensitivity

Soft ePTFE materials, such as gaskets, can be easily damaged by scratching or over-compression during installation. Proper handling and adherence to torque specifications are critical to achieving a successful seal.

Making the Right Choice for Your Application

Selecting ePTFE is a decision driven by the need for uncompromising performance in a specific area.

- If your primary focus is purity and biocompatibility: ePTFE is an industry standard for medical devices, pharmaceutical processing, and food-grade seals.

- If your primary focus is reliability in extreme environments: Its thermal stability and durability make it essential for critical aerospace, energy, and automotive components.

- If your primary focus is high-frequency signal integrity: The low dielectric constant of ePTFE is unmatched for advanced telecommunications and data cables.

- If your primary focus is sealing aggressive or corrosive media: ePTFE gaskets and liners provide one of the most reliable solutions for the chemical processing industry.

Ultimately, industries turn to ePTFE when performance is non-negotiable and failure is not an option.

Summary Table:

| Industry | Key ePTFE Applications | Primary Property Leveraged |

|---|---|---|

| Medical | Sutures, vascular grafts, implants | Biocompatibility, microporosity |

| Aerospace | Wire harness sleeves, seals | Thermal stability, chemical resistance |

| Automotive | Cable assemblies, gaskets | Durability, temperature resistance |

| Chemical Processing | Seals, liners, gaskets | Chemical inertness |

| Telecommunications | High-speed data cables | Superior electrical insulation |

| Pharmaceutical | Filtration systems, seals | Purity, chemical resistance |

Need High-Performance PTFE Components for Your Critical Applications?

KINTEK specializes in manufacturing precision PTFE and ePTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures materials that meet the most demanding performance standards.

Contact us today to discuss your project requirements and discover how our custom fabrication can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability