In short, Polytetrafluoroethylene (PTFE) is suitable for solar panel manufacturing because of its exceptional resilience. Its ability to withstand extreme heat up to 260°C (500°F), coupled with near-total immunity to UV radiation, moisture, and chemical exposure, makes it an ideal material for protecting sensitive solar components over a decades-long lifespan.

The core reason for using PTFE is not just one property, but its unique combination of thermal, chemical, and environmental resistances. It acts as a durable shield, ensuring the panel survives both the high-heat manufacturing process and decades of harsh outdoor conditions.

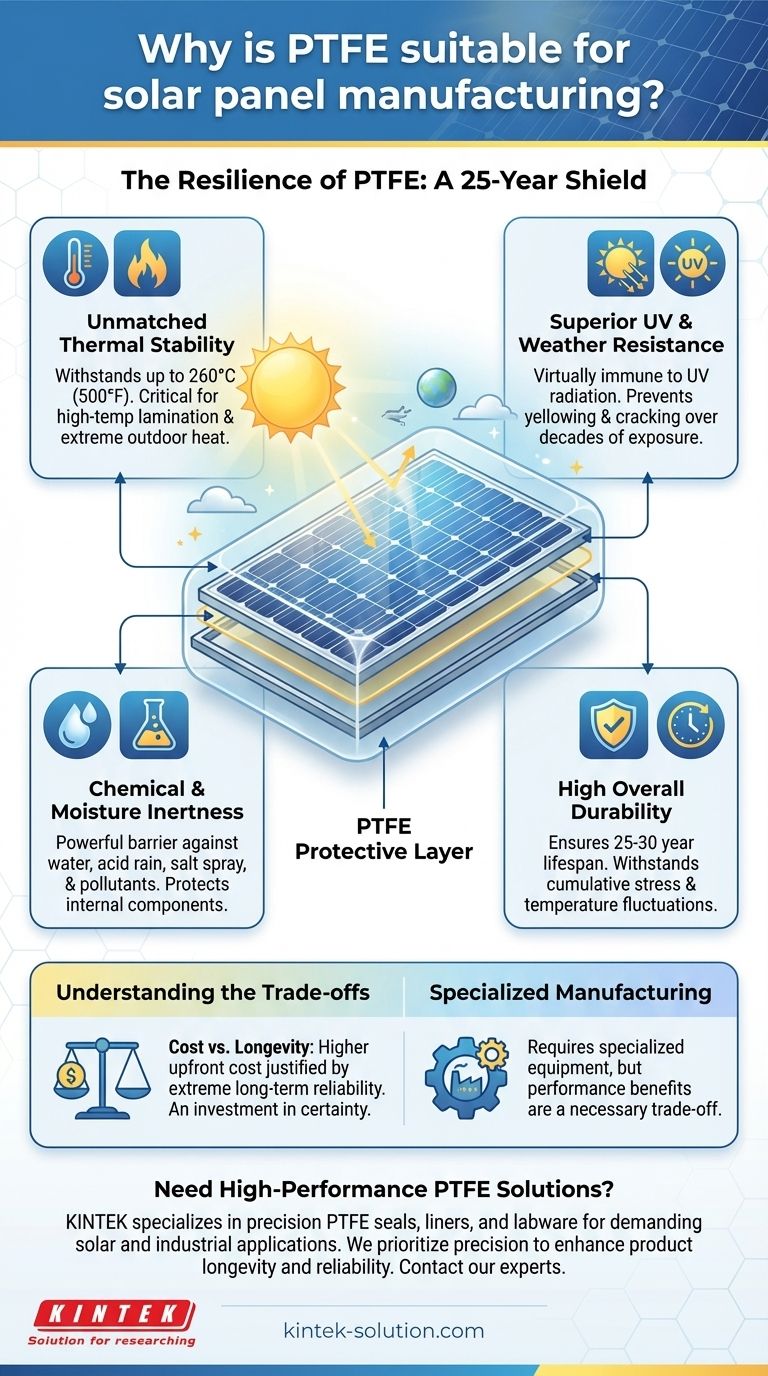

The Core Challenge: A 25-Year Battle Against the Elements

A solar panel is an asset expected to perform reliably for 25 to 30 years. During this time, it is permanently exposed to a hostile environment.

Materials used in its construction must endure relentless UV radiation, daily and seasonal temperature swings, humidity, rain, and chemical pollutants. Most materials degrade under this constant stress, but PTFE is uniquely equipped to handle it.

Key Properties of PTFE for Solar Manufacturing

Unmatched Thermal Stability

PTFE can withstand continuous service temperatures as high as 260°C (500°F). This is critical for two reasons.

First, it easily endures the high-temperature lamination process used to encapsulate the solar cells during manufacturing. Second, it remains stable even in the extreme heat that panels experience on rooftops in sunny climates.

Superior UV and Weather Resistance

UV radiation is the primary enemy of most plastics, causing them to become brittle, crack, and lose their protective qualities.

PTFE is virtually unaffected by UV light. This inherent resistance ensures it will not degrade, yellow, or fail over decades of direct sun exposure, maintaining the panel's structural integrity.

Chemical and Moisture Inertness

PTFE is one of the most chemically inert materials known. It provides a powerful barrier against environmental factors that would corrode lesser materials.

This includes resistance to water, acid rain, salt spray in coastal areas, and other atmospheric pollutants, protecting the delicate internal workings of the solar panel.

High Overall Durability

The combination of thermal, UV, and chemical resistance results in exceptional durability. PTFE withstands the cumulative stress of temperature fluctuations and harsh weather without losing its essential protective properties.

Understanding the Trade-offs

Cost vs. Longevity

PTFE is a high-performance fluoropolymer, which makes it more expensive than common plastics.

However, this higher upfront cost is justified by the need for extreme long-term reliability. Using a cheaper, less durable material would risk premature panel failure, undermining the entire economic basis of a solar installation.

Manufacturing Considerations

While highly effective, fluoropolymers like PTFE can require specialized equipment and processes compared to other materials.

Engineers must account for these factors in the design and setup of the manufacturing line, but the performance benefits are considered a necessary trade-off for producing a long-lasting, warrantable product.

Making the Right Choice for Your Goal

The selection of PTFE is a strategic decision rooted in the fundamental requirements of solar technology.

- If your primary focus is long-term reliability and warranty: PTFE's unparalleled resistance to UV, heat, and moisture is the foundation for a product that can be warrantied for 25+ years.

- If your primary focus is performance in extreme climates: Its wide operating temperature range and weather durability make it essential for panels deployed in hot deserts or harsh northern regions.

- If your primary focus is consistent manufacturing output: PTFE's stability during the high-temperature lamination process ensures a reliable and repeatable production outcome.

Ultimately, choosing a material like PTFE is an investment in certainty, ensuring the solar panel can deliver on its promise of clean energy for decades to come.

Summary Table:

| Property | Benefit for Solar Panels |

|---|---|

| Thermal Stability | Withstands high-temperature lamination & extreme outdoor heat up to 260°C (500°F). |

| UV Resistance | Virtually immune to sun damage, preventing brittleness and failure over decades. |

| Chemical Inertness | Protects against moisture, acid rain, salt spray, and pollutants. |

| Overall Durability | Ensures panel integrity and performance for a 25-30 year lifespan. |

Need high-performance PTFE components for your solar panels or other demanding applications?

KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware that deliver the unmatched durability and chemical resistance your products require. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we prioritize precision production to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance the longevity and reliability of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials