At its core, Perfluoroalkoxy (PFA) is a high-performance fluoropolymer prized for its unique combination of properties. It maintains performance characteristics similar to the well-known PTFE but adds the crucial advantage of being melt-processable, allowing it to be fabricated into more complex shapes.

PFA's defining characteristic is not a single attribute, but its powerful balance: it delivers the extreme temperature and chemical resistance of elite fluoropolymers while offering the design freedom of conventional thermoplastics like injection molding and extrusion.

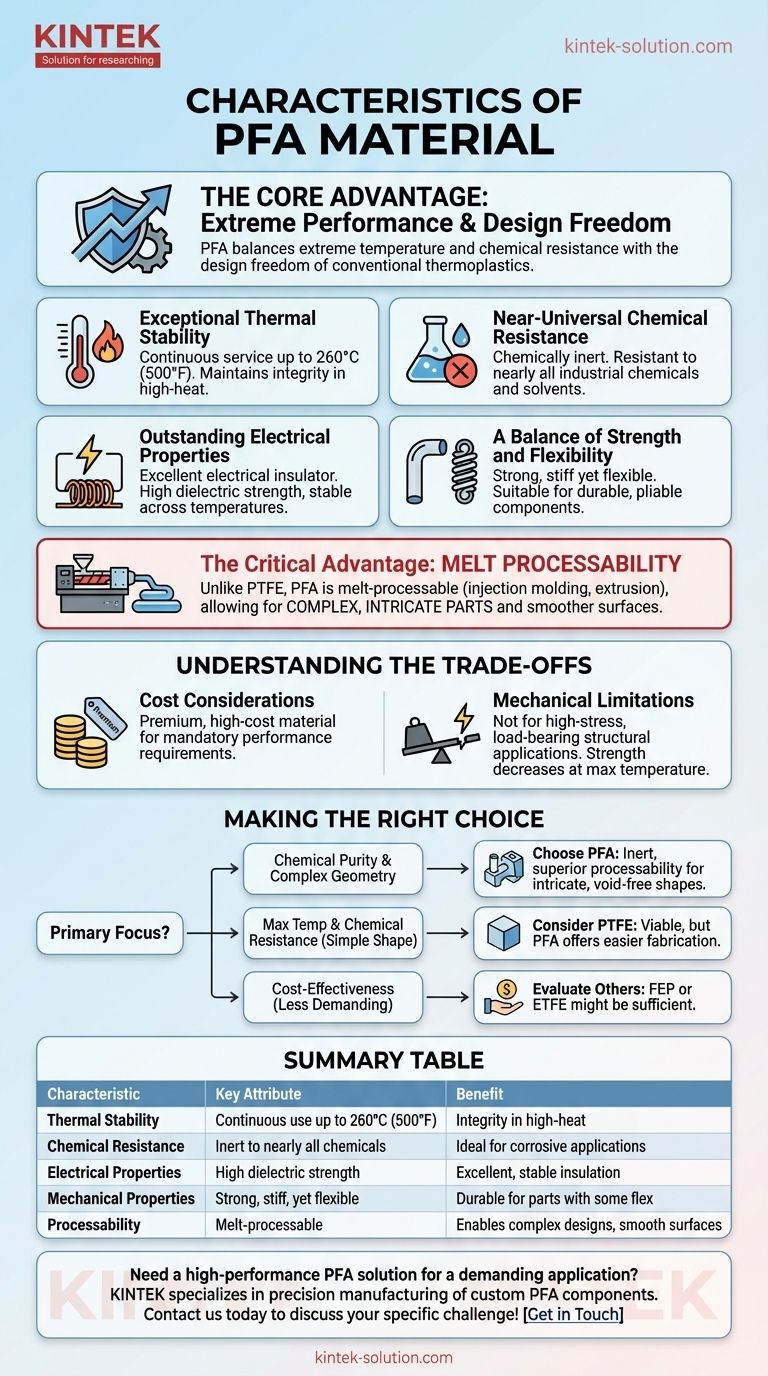

The Core Properties of PFA

To understand where PFA fits, we must break down its primary material characteristics. Each property makes it suitable for demanding industrial environments where component failure is not an option.

Exceptional Thermal Stability

PFA is capable of continuous service at temperatures up to 260°C (500°F). This high-temperature resistance allows it to maintain its mechanical integrity and electrical properties in environments that would degrade most other polymers.

Near-Universal Chemical Resistance

Like other fluoropolymers, PFA is chemically inert and resistant to nearly all industrial chemicals, solvents, and corrosive agents. This makes it an essential material for fluid handling components in the chemical processing and semiconductor industries.

Outstanding Electrical Properties

PFA is an excellent electrical insulator with a high dielectric strength. Its properties remain stable across a wide range of temperatures and frequencies, making it ideal for high-performance wire and cable insulation.

A Balance of Strength and Flexibility

While PFA is considered one of the stronger and stiffer fluoropolymers, it also possesses excellent flexibility. This unique combination allows it to be used for durable yet pliable components like tubing, linings, and bellows that must withstand repeated flexing.

The Critical Advantage: Melt Processability

The single most important differentiator for PFA, especially when compared to PTFE, is how it can be manufactured.

Why Processability Matters

Unlike PTFE, which cannot be truly melt-processed, PFA can be easily handled by conventional thermoplastic methods. It flows when melted, allowing for injection molding and extrusion.

The Impact on Design Freedom

This processability unlocks the ability to create complex, intricate parts with tight tolerances. It also produces smoother, less porous surfaces, which is critical for applications demanding high purity and preventing contamination, such as in semiconductor manufacturing.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective technical advisor means acknowledging the limitations.

Cost Considerations

PFA is a premium, high-cost material. Its use is typically justified only in applications where its specific performance characteristics are a mandatory requirement and lower-cost alternatives would fail.

Mechanical Limitations

While strong for a polymer, PFA is not a substitute for metal in high-stress, load-bearing structural applications. Its mechanical strength also decreases as it approaches its maximum service temperature.

Making the Right Choice for Your Application

Selecting PFA depends entirely on the specific demands of your project.

- If your primary focus is chemical purity and complex part geometry: PFA is an ideal choice due to its inertness and superior melt-processability for creating void-free, intricate shapes.

- If your primary focus is maximum temperature and chemical resistance on a simple shape: PTFE may be a viable alternative, but PFA offers easier fabrication and better mechanical properties at elevated temperatures.

- If your primary focus is cost-effectiveness in a less demanding environment: PFA is likely overkill, and you should evaluate other fluoropolymers like FEP or ETFE.

By understanding PFA's unique balance of extreme performance and practical processability, you can specify it confidently for applications where reliability is paramount.

Summary Table:

| Characteristic | Key Attribute | Benefit |

|---|---|---|

| Thermal Stability | Continuous use up to 260°C (500°F) | Maintains integrity in high-heat environments |

| Chemical Resistance | Inert to nearly all industrial chemicals | Ideal for corrosive and high-purity applications |

| Electrical Properties | High dielectric strength | Excellent, stable electrical insulation |

| Mechanical Properties | Strong, stiff, yet flexible | Durable for parts requiring some flex, like tubing |

| Processability | Melt-processable (injection molding, extrusion) | Enables complex, intricate part designs with smooth surfaces |

Need a high-performance material solution for a demanding application?

PFA's unique combination of extreme chemical/thermal resistance and design flexibility makes it ideal for critical components in the semiconductor, medical, and laboratory industries.

At KINTEK, we specialize in precision manufacturing of high-performance polymer components, including custom PFA fabrication. From prototypes to high-volume orders, we deliver the reliability and purity your application demands.

Contact us today to discuss how our PFA expertise can solve your specific challenge! Get in Touch

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Evaporating Dishes for Diverse Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- How does the PTFE bottle perform in terms of chemical resistance? Unmatched Protection for Harsh Chemicals

- What are the temperature limits for the PTFE bottle? Ensure Safety from -200°C to 260°C

- What are the characteristics of narrow mouth PTFE laboratory bottles? Superior Chemical Resistance & Purity