In a harsh chemical environment, material failure is not an option. Teflon seals are the industry standard for these applications because their fundamental molecular structure makes them almost universally inert. They do not corrode, degrade, or swell when exposed to the vast majority of aggressive acids, bases, and solvents, ensuring reliable and long-lasting performance.

The core reason Teflon excels is its chemical makeup. The incredibly strong carbon-fluorine bonds create a non-reactive surface, preventing chemical attack and ensuring the seal maintains its integrity and prevents leaks where other materials would quickly fail.

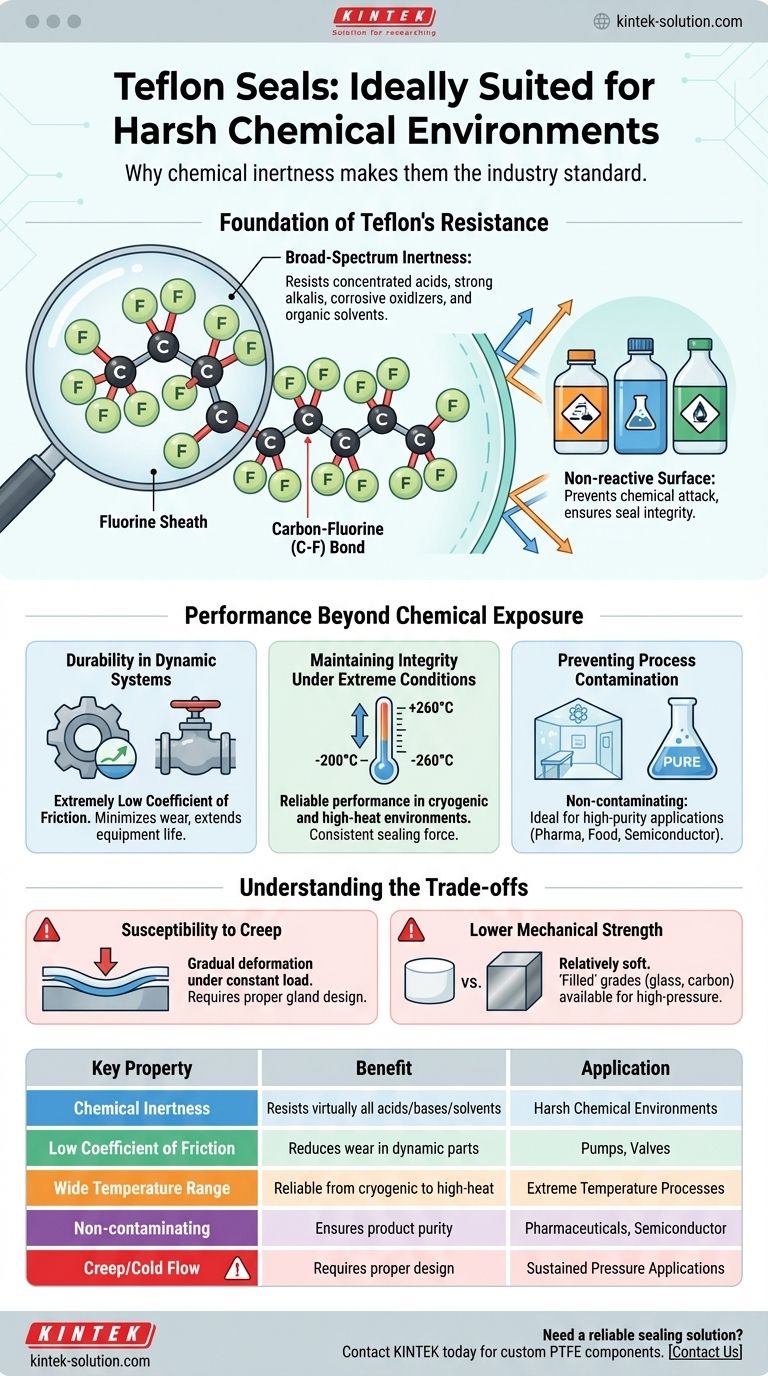

The Foundation of Teflon's Resistance

The exceptional performance of Teflon, technically known as Polytetrafluoroethylene (PTFE), isn't accidental. It's a direct result of its unique molecular architecture, which provides a level of chemical defense that is nearly unmatched by other polymers.

The Power of the Carbon-Fluorine Bond

At the heart of Teflon's resilience is the carbon-fluorine (C-F) bond, one of the strongest single bonds in organic chemistry.

In the PTFE molecule, a chain of carbon atoms is completely surrounded by a dense sheath of fluorine atoms. This fluorine sheath effectively shields the vulnerable carbon backbone from any potential chemical attack.

Broad-Spectrum Inertness

This molecular shield gives Teflon near-universal chemical resistance. It remains unaffected by exposure to a vast range of aggressive substances.

This includes concentrated acids, strong alkalis, corrosive oxidizers, and nearly all organic solvents. Unlike other materials that may resist some chemicals but not others, Teflon's defense is broad and reliable.

Preventing Process Contamination

Because Teflon is so inert, it does not react with or leach particles into the media it is sealing.

This is a critical advantage in high-purity applications like pharmaceutical manufacturing, food processing, or semiconductor fabrication, where even trace amounts of contamination can ruin a batch.

Performance Beyond Chemical Exposure

While chemical inertness is the primary reason for choosing Teflon, its physical properties provide additional benefits that contribute to its role as a premier sealing material in demanding conditions.

Durability in Dynamic Systems

Teflon possesses an extremely low coefficient of friction, meaning it is very slippery.

In applications with moving parts, such as in pumps or valves, this low-friction surface minimizes wear and abrasion. This extends the operational life of both the seal and the equipment itself.

Maintaining Integrity Under Extreme Conditions

Teflon maintains its excellent properties across a wide temperature range, performing reliably in both cryogenic conditions and high-heat environments.

This stability ensures that the seal will not become brittle at low temperatures or soften excessively at high temperatures, providing a consistent and predictable sealing force.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's limitations to ensure it is specified correctly.

Susceptibility to Creep

Under sustained pressure and temperature, Teflon can be subject to "creep" or "cold flow." This is a gradual deformation of the material under a constant load.

Engineers must account for this in the design of the seal and gland, as excessive creep can lead to a loss of sealing pressure over time.

Lower Mechanical Strength

Compared to metals or high-performance engineered plastics, Teflon is a relatively soft material.

In very high-pressure applications or situations involving significant mechanical stress, unfilled PTFE might not be suitable. However, this can often be mitigated by using "filled" Teflon grades, which incorporate materials like glass, carbon, or bronze to improve strength and creep resistance.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's properties to the primary demands of your system.

- If your primary focus is absolute chemical inertness: Teflon is the unparalleled choice, offering peace of mind when dealing with highly corrosive or mixed chemical streams.

- If your primary focus is product purity: The non-reactive and non-leaching nature of Teflon makes it an essential material for protecting the integrity of sensitive process media.

- If your primary focus is high-pressure mechanical performance: Consider filled Teflon grades or consult an engineer to ensure the material's mechanical limits are not exceeded in your design.

Understanding both the unparalleled chemical resistance and the physical trade-offs of Teflon is the key to engineering a truly resilient and reliable system.

Summary Table:

| Key Property | Benefit in Harsh Chemical Environments |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents |

| Low Coefficient of Friction | Reduces wear in dynamic applications like pumps and valves |

| Wide Temperature Range | Performs reliably from cryogenic to high-heat conditions |

| Non-contaminating | Ideal for high-purity industries like pharmaceuticals and semiconductors |

| Trade-off: Creep/Cold Flow | Requires proper gland design to maintain sealing pressure over time |

Need a reliable sealing solution for your most demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems are protected against even the most aggressive chemicals, preventing downtime and contamination.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific needs.

Contact us today to discuss your project requirements and let our experts provide a solution that guarantees longevity and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of PTFE-free bushings? Enhance Durability & Environmental Compliance

- What is virgin PTFE sheet and how is it different from Teflon? | Choosing the Right Grade for Your Application

- What are some applications of PTFE in the medical field? Key Uses in Implants & Medical Devices

- How does a PTFE lined butterfly valve compare to other valve types? A Guide to Superior Sealing & Chemical Resistance

- Where are PTFE energized seals used in oil and gas operations? Essential Sealing Solutions for Harsh Environments

- What is FEP and how does it differ from PTFE? Key Differences in Performance & Manufacturing

- Why is PTFE preferred in CNC machining for product design? Unlock High-Performance Components

- What industrial applications utilize extruded PTFE rods? Key Uses in Chemical, Aerospace & More