In short, Teflon bushings are essential because their unique properties—extremely low friction, chemical resistance, and temperature stability—allow machinery to run smoother, longer, and with significantly less maintenance. They serve as a critical interface between moving parts, absorbing wear and preventing damage to more expensive components.

The true value of a Teflon bushing isn't just what it is, but what it eliminates. It removes the need for constant lubrication, reduces wear-related downtime, and protects critical machinery from premature failure, directly impacting operational efficiency and profitability.

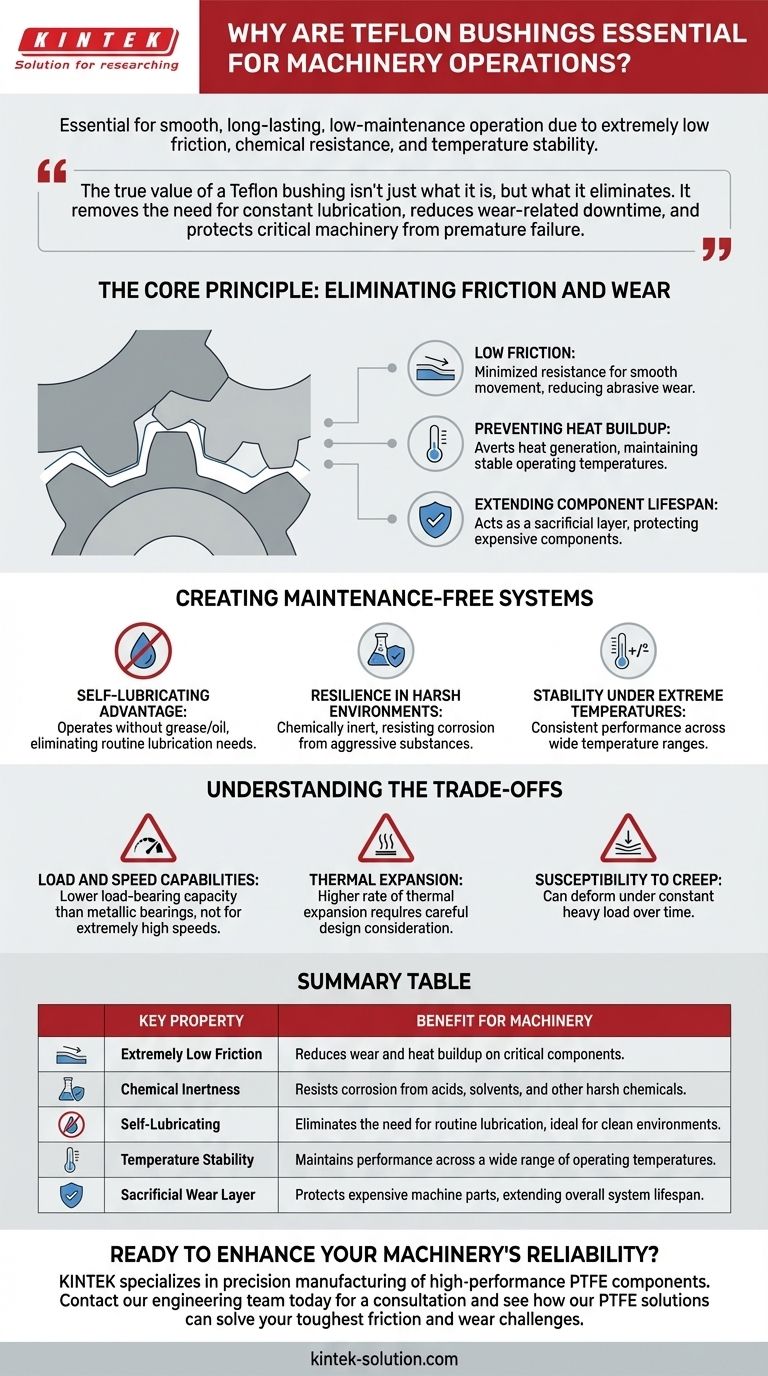

The Core Principle: Eliminating Friction and Wear

The primary function of any bushing is to provide a low-wear surface between two moving parts. Teflon, the brand name for Polytetrafluoroethylene (PTFE), accomplishes this with exceptional efficiency.

The Power of Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This allows machine components, such as those in motors, pumps, and gears, to slide against each other with minimal resistance.

This smooth movement directly reduces the abrasive wear that grinds down critical parts over time.

Preventing Heat Buildup

High friction generates heat, a primary enemy of machinery. Excessive heat can cause parts to warp, degrade lubricants, and lead to catastrophic failure.

By minimizing friction, Teflon bushings prevent this dangerous heat buildup, helping to maintain stable operating temperatures and prolonging the lifespan of the entire assembly.

Extending Component Lifespan

The combination of reduced friction and lower heat means less stress on moving parts. In high-contact applications like pump housings, valve guides, and conveyor systems, Teflon bushings act as a sacrificial layer.

This small, inexpensive component absorbs the wear and tear, protecting the far more expensive and difficult-to-replace parts it is installed in.

Creating Maintenance-Free Systems

Beyond simply reducing wear, Teflon's properties enable engineers to design systems that are more resilient and require less human intervention.

The Self-Lubricating Advantage

One of the most significant benefits of Teflon bushings is their ability to operate without grease or oil. This self-lubricating quality is invaluable.

It eliminates the time and cost associated with routine lubrication and is ideal for applications where lubricants could contaminate products, such as in food processing or textile equipment.

Resilience in Harsh Environments

Teflon is chemically inert, meaning it does not react with most corrosive substances. This makes it the perfect choice for machinery exposed to acids, solvents, or other aggressive chemicals.

Where a metal bushing would corrode and fail, a Teflon bushing remains stable and functional.

Stability Under Extreme Temperatures

Teflon maintains its key properties across a very wide temperature range. This allows it to be used reliably in equipment that experiences both extreme cold and high heat, ensuring consistent performance.

Understanding the Trade-offs

While highly effective, Teflon bushings are not a universal solution. An objective assessment requires understanding their limitations.

Load and Speed Capabilities

Compared to metallic bearings, standard PTFE bushings generally have lower load-bearing capacity and are not suited for extremely high-speed rotational applications. Under heavy loads, the material can deform.

Thermal Expansion

Teflon has a higher rate of thermal expansion than metals. This must be accounted for during the design and installation process to ensure proper clearances are maintained as operating temperatures change.

Susceptibility to Creep

Under a constant, heavy load, PTFE can slowly deform over time in a process known as "creep." This makes material selection and component design critical in high-pressure applications.

Making the Right Choice for Your Goal

Selecting the right bushing material depends entirely on the operational demands of your machinery.

- If your primary focus is reducing routine maintenance: Teflon is ideal for creating self-lubricating, "fit-and-forget" systems, especially in hard-to-access locations.

- If your machinery operates in a corrosive or clean environment: The chemical inertness and self-lubricating nature of Teflon provide unparalleled protection and cleanliness.

- If you need to prevent wear on critical, high-cost components: Use Teflon bushings as a low-cost, sacrificial interface to absorb friction and protect expensive parts from damage.

Ultimately, these small components deliver a massive return on investment by enhancing machinery reliability and driving down long-term operational costs.

Summary Table:

| Key Property | Benefit for Machinery |

|---|---|

| Extremely Low Friction | Reduces wear and heat buildup on critical components. |

| Chemical Inertness | Resists corrosion from acids, solvents, and other harsh chemicals. |

| Self-Lubricating | Eliminates the need for routine lubrication, ideal for clean environments. |

| Temperature Stability | Maintains performance across a wide range of operating temperatures. |

| Sacrificial Wear Layer | Protects expensive machine parts, extending overall system lifespan. |

Ready to enhance your machinery's reliability and reduce operational costs?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bushings, seals, and liners. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get a component perfectly suited to your application's demands.

Contact our engineering team today for a consultation and see how our PTFE solutions can solve your toughest friction and wear challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are filled PTFE bushes and why are fillers added? Enhance Wear Resistance & Load Capacity

- What operating conditions are PTFE-lined plug valves particularly suitable for? Control Corrosive & High-Purity Fluids

- How do lined valves compare to plastic pipes in terms of pressure and temperature resistance? Unlock Superior Performance

- What are the available sizes and thicknesses for PTFE sheets? A Guide for Engineers & Designers

- Why is PTFE preferred in petrochemical and chemical processing? Ensure Safety and Reliability

- Are PTFE lined butterfly valves cost-effective? Maximize ROI in Corrosive Applications

- What are the key properties of solid PTFE bushings? Master Low Friction & Chemical Resistance

- What advantages do Teflon O-rings offer compared to other materials? Unmatched Chemical & Thermal Resistance