PTFE is the preferred material in petrochemical and chemical processing due to its unique combination of near-total chemical inertness and high-temperature stability. This pairing ensures that critical components will not corrode, degrade, or fail when exposed to the industry's most aggressive acids, caustics, and high-heat environments, making it essential for both safety and operational reliability.

The central reason for PTFE's dominance is its profound chemical resistance. In an industry where material failure can lead to catastrophic safety incidents and costly downtime, PTFE provides a level of stability and durability that very few materials can match.

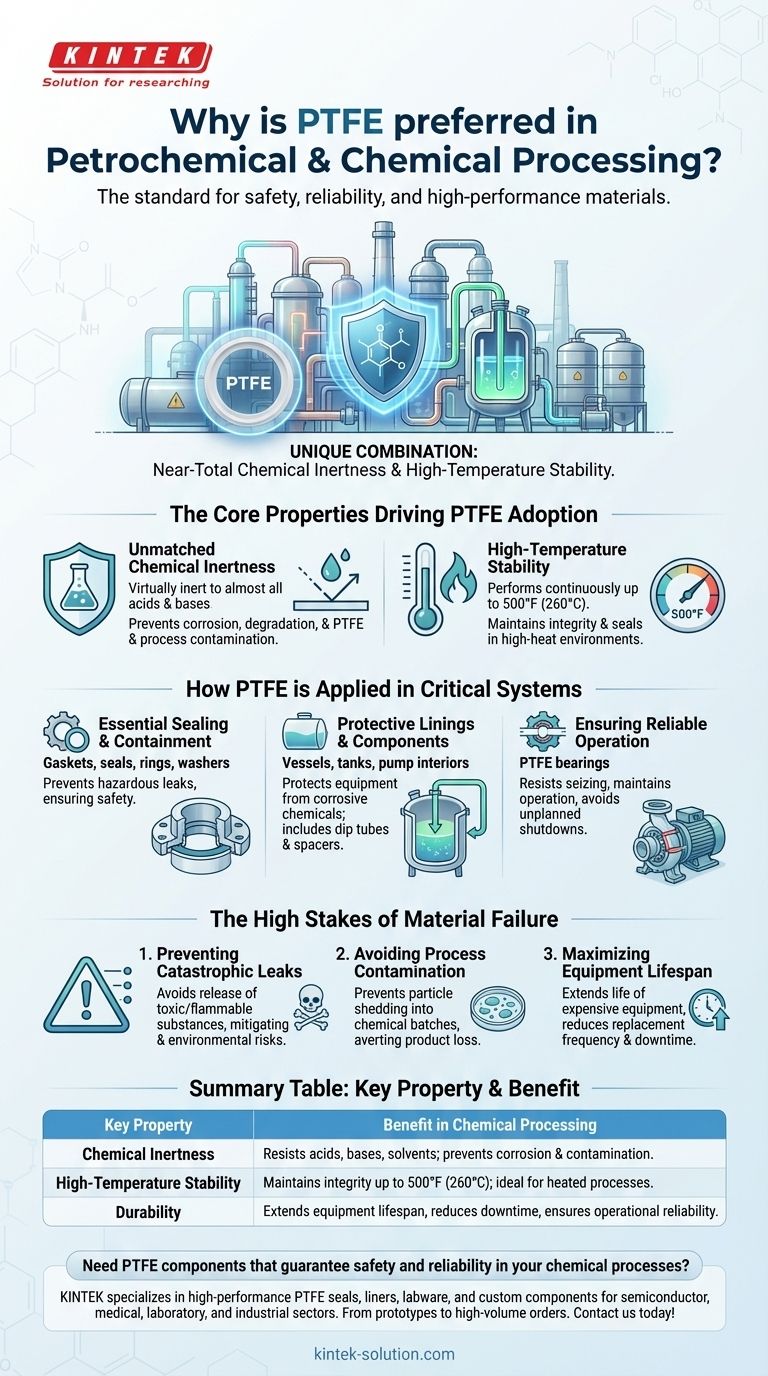

The Core Properties Driving PTFE Adoption

The selection of materials in chemical processing is a matter of extreme consequence. PTFE's fundamental characteristics directly address the industry's most demanding challenges.

Unmatched Chemical Inertness

PTFE is virtually inert and unaffected by almost all known acids and bases. This property is not just a benefit; it is a fundamental requirement.

It means that components made from PTFE will not corrode or degrade, even with continuous exposure to highly reactive chemicals. This prevents equipment failure and process contamination.

High-Temperature Stability

Many chemical processes occur at elevated temperatures. PTFE reliably performs in continuous service environments up to 500°F (260°C).

This thermal resistance ensures that its physical integrity and chemical inertness are maintained, preventing seals from failing or linings from degrading under operational heat.

How PTFE is Applied in Critical Systems

PTFE's properties make it the default choice for components where reliability is non-negotiable. Its use is focused on points of high stress, both chemical and physical.

Essential Sealing and Containment

The most common applications are in sealing. Components like gaskets, seals, rings, and washers made from PTFE prevent the leakage of hazardous and corrosive materials.

A failed seal can have severe consequences, making PTFE's reliability a critical safety feature.

Protective Linings and Components

PTFE is used to line vessels, tanks, and pump interiors. This protects the structural metal of the equipment from the corrosive chemicals being processed or transported.

It also serves in components like dip tubes and spacers, which are directly immersed in aggressive chemical mixtures.

Ensuring Reliable Operation

In equipment like pumps, PTFE bearings are preferred because their chemical resistance ensures they will not seize or degrade.

This reliability is crucial for maintaining consistent operation and avoiding unplanned shutdowns for maintenance.

The High Stakes of Material Failure

In the chemical and petrochemical sectors, choosing the wrong material is not an option. The consequences of failure underscore why a robust material like PTFE is considered the standard.

Preventing Catastrophic Leaks

A degraded gasket or seal can lead to the release of toxic, flammable, or corrosive substances. This poses an immediate threat to personnel safety and the environment. PTFE's stability directly mitigates this risk.

Avoiding Process Contamination

If a vessel lining or pump component begins to break down, it can shed particles into the chemical batch. This contamination can ruin an entire product run, leading to significant financial loss.

Maximizing Equipment Lifespan

Using PTFE extends the life of expensive equipment by protecting it from its corrosive contents. This reduces the frequency of costly replacements and minimizes operational downtime, directly impacting profitability.

Making the Right Choice for Your Application

Your specific goal will determine how you leverage PTFE's advantages, but the underlying principles of safety and reliability remain constant.

- If your primary focus is safety and containment: PTFE is the benchmark for seals, gaskets, and linings that must reliably contain aggressive chemicals and prevent dangerous leaks.

- If your primary focus is process purity and reliability: Using PTFE for pump interiors, vessel linings, and bearings ensures your equipment does not corrode, contaminate your product, or cause unexpected shutdowns.

- If your primary focus is durability in high-heat environments: PTFE's ability to function up to 500°F makes it essential for components within heated chemical reactors and processing lines.

Ultimately, PTFE is foundational to the chemical processing industry because it provides a predictable and reliable barrier against the world's most aggressive chemicals.

Summary Table:

| Key Property | Benefit in Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents corrosion and contamination. |

| High-Temperature Stability | Maintains integrity up to 500°F (260°C); ideal for heated processes. |

| Durability | Extends equipment lifespan, reduces downtime, and ensures operational reliability. |

Need PTFE components that guarantee safety and reliability in your chemical processes? KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our precision production ensures your equipment withstands aggressive chemicals and high temperatures. Contact us today to discuss your specific requirements and enhance your operational security!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the advantages and disadvantages of Virgin PTFE as a valve seat material? Maximize Performance & Avoid Failure

- How does PTFE benefit the electronics industry? Achieve Superior Signal Integrity & Reliability

- Why are PTFE washers used in applications requiring low friction? Unlock Superior Performance with KINTEK

- What are some specific applications of PTFE gaskets in the chemical processing industry? Prevent Leaks in Corrosive Systems

- What are the main benefits of PTFE envelope gaskets? Achieve Superior Chemical Resistance and Sealing Integrity

- What safety features do PTFE lined butterfly valves offer? Ensure Leak-Free Containment of Hazardous Media

- How do PTFE lined valves ensure longevity in harsh chemical environments? Achieve Decades of Reliable Service

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings