The primary advantages of Teflon O-rings stem from their unparalleled chemical inertness, extremely wide temperature tolerance, and exceptionally low friction. These properties make them the material of choice for sealing applications in harsh chemical, high-temperature, or dynamic environments where conventional elastomeric seals would quickly degrade and fail.

Teflon (PTFE) O-rings are less a general-purpose seal and more a specialized solution. You choose them when the operational environment—be it aggressive chemicals, extreme temperatures, or high-wear dynamic motion—is simply too hostile for standard rubber or plastic materials.

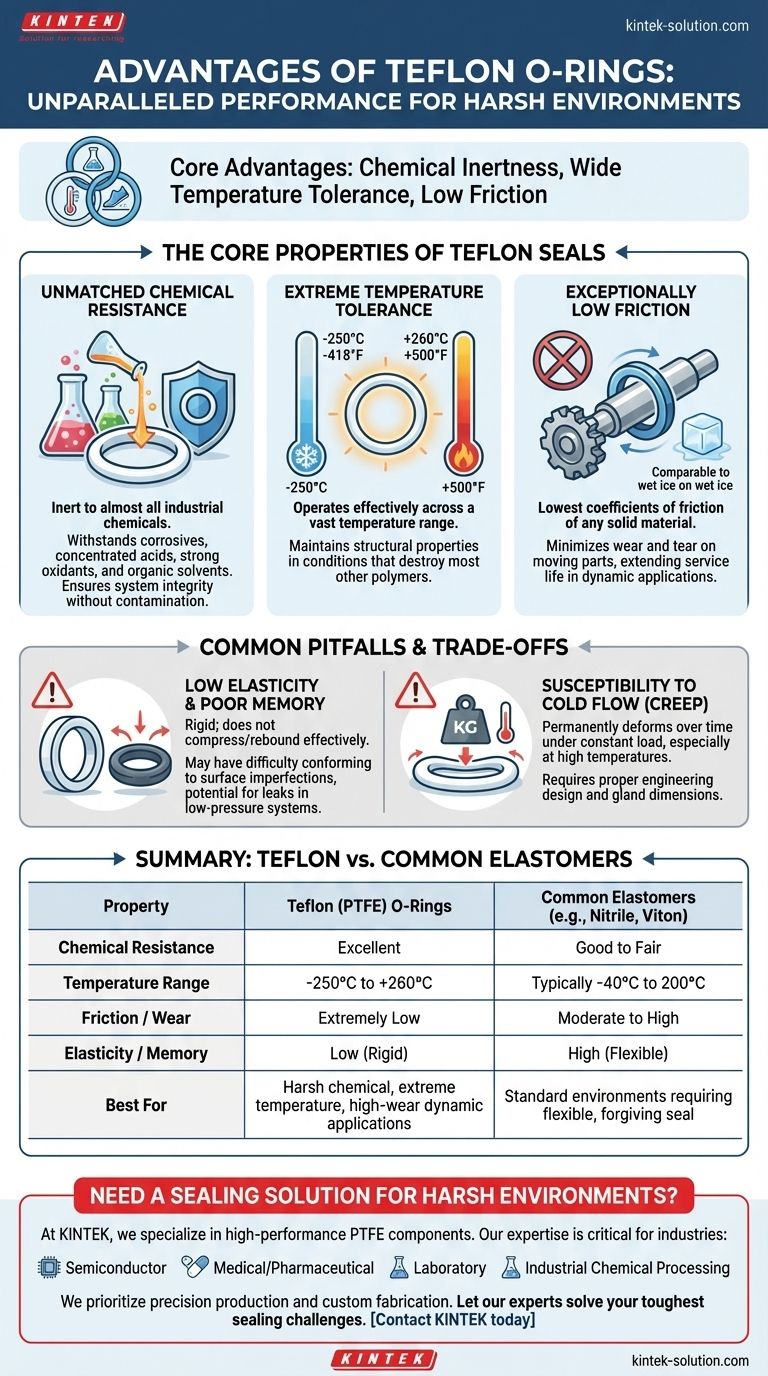

The Core Properties of Teflon Seals

To understand when to use a Teflon O-ring, it's essential to understand its fundamental material characteristics. It behaves very differently from a typical rubber O-ring.

Unmatched Chemical Resistance

Teflon is practically inert to almost all industrial chemicals. It can withstand prolonged contact with highly corrosive substances like concentrated acids, alkalis, strong oxidants, and a vast range of organic solvents.

This robust stability ensures the seal maintains its integrity and does not contaminate the system's media, which is critical in chemical processing and food production.

Extreme Temperature Tolerance

Teflon operates effectively across a vast temperature range, typically from -250°C to +260°C (-418°F to +500°F).

While many plastics become brittle at low temperatures or deform at high temperatures, Teflon maintains its structural properties in conditions that would destroy most other polymers.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This "slipperiness" is a major advantage in dynamic applications.

Its non-stick surface minimizes wear and tear on moving parts like shafts in pumps, mixers, and agitators, leading to a longer service life for both the seal and the equipment.

Common Pitfalls and Trade-offs

While its properties are exceptional, solid Teflon is not a perfect drop-in replacement for rubber O-rings. Its unique nature introduces critical trade-offs that must be considered during design.

Low Elasticity and Poor Memory

Unlike true elastomers (like Nitrile or Viton), solid Teflon is a rigid material. It does not compress and rebound effectively.

This lack of "memory" or "springiness" means it can have difficulty conforming to surface imperfections in a gland, potentially leading to leaks, especially in low-pressure systems.

Susceptibility to Cold Flow (Creep)

Under a constant compressive load, especially at elevated temperatures, Teflon can permanently deform over time. This phenomenon, known as creep or "cold flow," can cause the seal to loosen and eventually fail.

Proper engineering design, including correct gland dimensions and avoiding excessive squeeze, is critical to mitigating this risk.

Making the Right Choice for Your Application

Selecting a sealing material requires matching its properties to the demands of the operating environment.

- If your primary focus is sealing in aggressive chemicals or extreme temperatures: Teflon is often the only viable choice, as common elastomers would chemically degrade or physically fail.

- If your primary focus is reducing friction and wear in a dynamic system: Teflon's low-friction, non-stick surface provides superior durability and longevity for moving parts.

- If your primary focus is a simple static seal in a standard environment: A flexible elastomer like Nitrile, EPDM, or Viton will likely provide a more reliable, forgiving, and cost-effective seal.

Ultimately, choosing a Teflon O-ring is a decision to prioritize chemical and thermal resilience above the flexibility and sealing ease of a standard elastomer.

Summary Table:

| Property | Teflon (PTFE) O-Rings | Common Elastomers (e.g., Nitrile, Viton) |

|---|---|---|

| Chemical Resistance | Excellent (inert to most chemicals) | Good to Fair (varies by type) |

| Temperature Range | -250°C to +260°C (-418°F to +500°F) | Typically -40°C to 200°C (-40°F to 400°F) |

| Friction / Wear | Extremely Low | Moderate to High |

| Elasticity / Memory | Low (Rigid) | High (Flexible) |

| Best For | Harsh chemical, extreme temperature, and high-wear dynamic applications | Standard environments requiring a flexible, forgiving seal |

Need a sealing solution for harsh environments?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision Teflon O-rings, seals, liners, and custom labware. Our expertise is critical for industries where chemical resistance, extreme temperatures, and low friction are non-negotiable, such as:

- Semiconductor manufacturing

- Medical and pharmaceutical equipment

- Laboratory and analytical instrumentation

- Industrial chemical processing

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal your application demands.

Let our experts help you solve your toughest sealing challenges. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability