PTFE-lined plug valves are the definitive choice for applications that demand both exceptional chemical resistance and reliable, bubble-tight sealing. They are specifically engineered for systems handling corrosive or high-purity fluids, particularly under low-to-medium pressure and temperature conditions where preventing leaks and contamination is paramount.

The core value of a PTFE-lined plug valve lies in a powerful combination: the simple, robust sealing mechanism of a plug valve design married with the near-universal chemical inertness of a Polytetrafluoroethylene (PTFE) liner. This makes it a specialized tool for safely controlling challenging fluids.

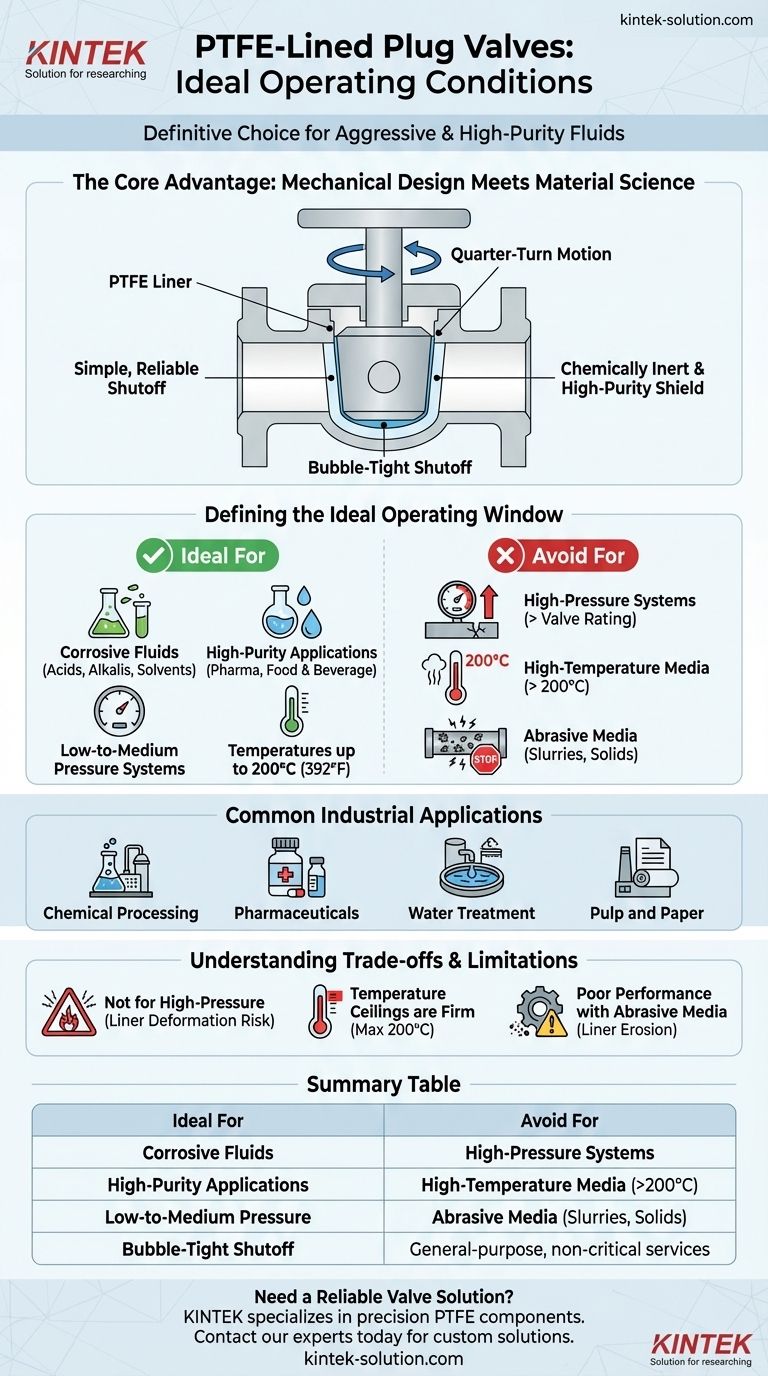

The Core Advantage: Mechanical Design Meets Material Science

To understand where these valves fit, you must first appreciate how their two key components work together. The synergy between the valve's structure and its lining material defines its capabilities.

The Plug Valve: Simple, Reliable Shutoff

A plug valve operates with a simple quarter-turn motion. This rotates a cylindrical or tapered "plug" with a bore in it to align with or block the flow path.

This design provides a large sealing area between the plug and the valve body. When properly engineered, this results in a very secure, leak-free seal known as bubble-tight shutoff.

The PTFE Liner: A Shield Against Corrosion and Contamination

The entire wetted surface of the valve—the body and the plug—is coated with a thick layer of PTFE. This polymer is renowned for its unique properties.

PTFE is one of the most chemically inert substances known, making it resistant to nearly all industrial chemicals, acids, and alkalis. It is also a high-purity material, meaning it will not leach contaminants into the process fluid, a critical factor in pharmaceutical and food production.

Defining the Ideal Operating Window

A PTFE-lined plug valve is not a universal solution. It is a precision instrument designed to excel within specific operational boundaries.

Fluid Compatibility: Where PTFE Excels

These valves are ideal for managing aggressive or sensitive liquids. Their application is driven by the liner's ability to resist chemical attack and maintain purity.

This includes fluids such as strong acids, alkalis, solvents, and chemical disinfectants found in water treatment. They are also standard in pharmaceutical and food & beverage industries for handling high-purity water, syrups, and other sensitive materials.

Pressure and Temperature Boundaries

The primary constraints for these valves are pressure and temperature. The term "relatively low" is key.

PTFE as a material can typically handle temperatures up to 200°C (392°F). However, the valve's maximum operating pressure is often interdependent with its temperature, and it is generally best suited for low-to-medium pressure applications.

Common Industrial Applications

The combination of leak-free performance and chemical resistance makes these valves prevalent across several industries:

- Chemical Processing: Handling aggressive reagents and intermediates.

- Pharmaceuticals: Transferring high-purity fluids where no contamination is tolerable.

- Water Treatment: Dosing chlorine, sodium hypochlorite, and other corrosive disinfectants.

- Pulp and Paper: Managing bleaching agents and other chemical additives.

Understanding the Trade-offs and Limitations

True expertise requires knowing not just what a tool does well, but also what it does not. Acknowledging the limitations of PTFE-lined plug valves is critical for proper selection.

Not for High-Pressure Systems

While excellent for low-to-medium pressure sealing, the PTFE liner can be compromised under very high-pressure conditions. Extreme pressures can risk deforming the liner or forcing fluid behind it, leading to premature failure.

Temperature Ceilings are Firm

The 200°C temperature limit is a significant ceiling. For applications involving high-temperature steam or other processes that exceed this threshold, you must turn to all-metal valve designs without polymeric liners.

Poor Performance with Abrasive Media

PTFE is a relatively soft material. It is not designed to handle fluids containing abrasive solids, such as slurries or mining tailings. Abrasive particles will quickly erode the liner, destroying the integrity of the seal and leading to valve failure.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE-lined plug valve is the correct technical solution for your specific operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE-lined plug valve is an excellent choice due to its near-universal chemical inertness and reliable shutoff.

- If your primary focus is maintaining fluid purity: This valve design is ideal for food, beverage, and pharmaceutical applications where preventing contamination is non-negotiable.

- If your system involves high pressures or abrasive solids: You should immediately explore other valve types, such as metal-seated ball valves or knife gate valves designed for these harsh conditions.

Ultimately, selecting the right valve is about matching the technology to the precise demands of the system.

Summary Table:

| Ideal For | Avoid For |

|---|---|

| Corrosive Fluids (acids, alkalis, solvents) | High-Pressure Systems (> valve rating) |

| High-Purity Applications (pharma, food & beverage) | High-Temperature Media (> 200°C / 392°F) |

| Low-to-Medium Pressure systems | Abrasive Media (slurries, solids) |

| Bubble-Tight Shutoff requirements | General-purpose, non-critical services |

Need a reliable valve for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-fabricated seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a valve solution that delivers exceptional chemical resistance and contamination-free performance, tailored to your specific operational requirements—from prototypes to high-volume orders.

Contact our experts today to discuss your application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications