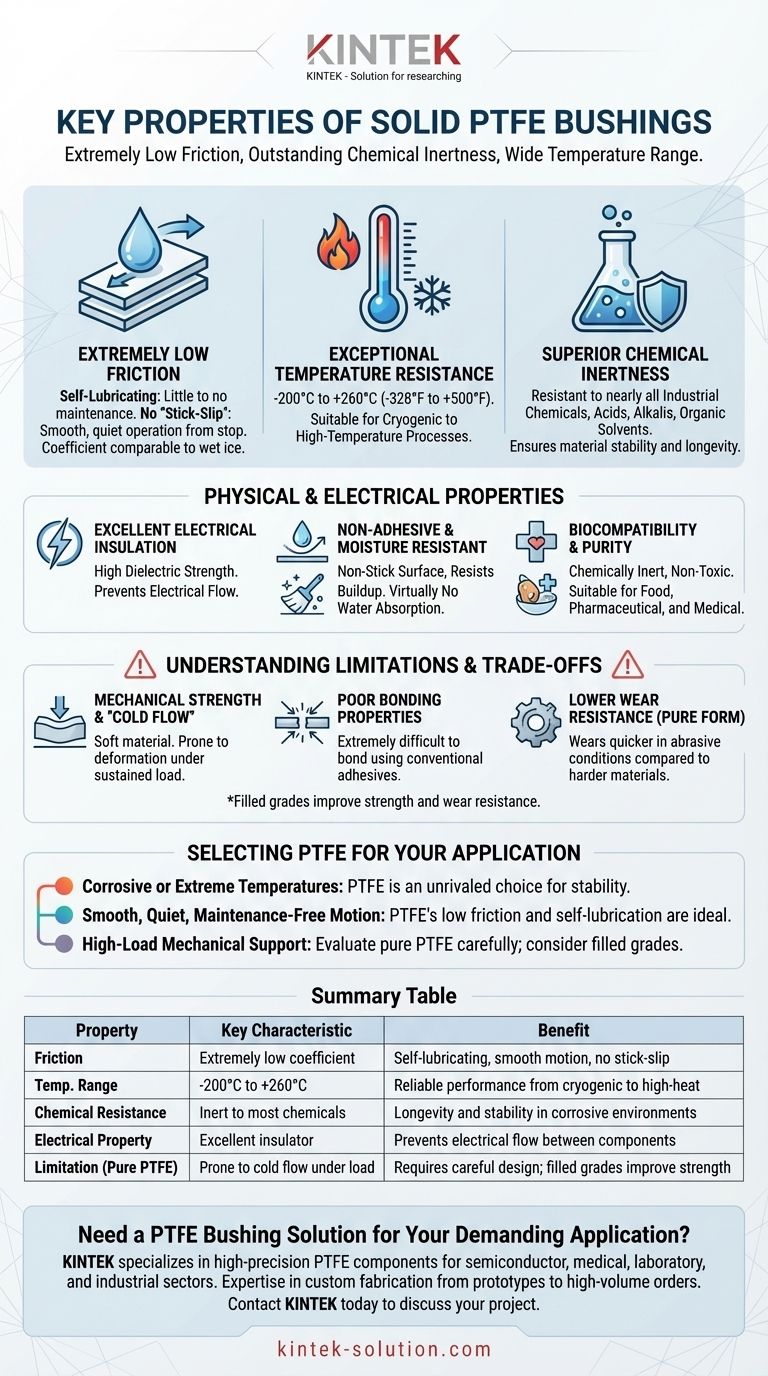

The defining properties of solid PTFE bushings are their extremely low friction, outstanding chemical inertness, and ability to perform across a vast temperature range. Composed of carbon and fluorine, this material is self-lubricating, non-absorbent, and an excellent electrical insulator, making it a specialized solution for demanding operational environments.

PTFE's unique combination of properties makes it a premier choice for applications where smooth motion is required in the presence of extreme temperatures or corrosive chemicals. However, its inherent softness means its mechanical limitations must be clearly understood.

Core Performance Characteristics

The primary advantages of PTFE stem from its unique molecular structure, which results in a set of highly desirable performance traits.

Extremely Low Coefficient of Friction

Solid PTFE has one of the lowest coefficients of friction of any known solid material, comparable to wet ice on wet ice. This results in self-lubricating performance that requires little to no maintenance.

This property also eliminates "stick-slip", the jerky motion that occurs when static friction is higher than dynamic friction, ensuring smooth and quiet operation from a complete stop.

Exceptional Temperature Resistance

PTFE bushings operate reliably across an exceptionally wide temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes them suitable for applications ranging from cryogenic equipment to high-temperature industrial processes where many other materials would fail.

Superior Chemical Inertness

The strong carbon-fluorine bonds in PTFE make it highly unreactive. It is resistant to nearly all industrial chemicals, acids, alkalis, and organic solvents.

This chemical stiffness ensures the bushing will not degrade or swell when exposed to corrosive substances, guaranteeing material stability and longevity.

Physical and Electrical Properties

Beyond its primary performance traits, PTFE possesses other physical characteristics that expand its use cases into sensitive and specialized fields.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength. This makes it an ideal choice for applications where a bushing must prevent the flow of electricity between components.

Non-Adhesive and Moisture Resistant

The material has a non-stick surface that resists contamination and buildup, which also simplifies cleaning.

Furthermore, PTFE has virtually no water absorption, ensuring its dimensions and properties remain stable even in humid or submerged conditions.

Biocompatibility and Purity

Because it is chemically inert, insoluble, and non-toxic, pure PTFE is suitable for sensitive applications. It is frequently used in food production, pharmaceutical, and medical equipment where purity is critical.

Understanding the Limitations and Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Its limitations are primarily mechanical and must be considered during the design phase.

Mechanical Strength and "Cold Flow"

Pure PTFE is a relatively soft material. Under a sustained, heavy load, it can be prone to "cold flow" or creep, meaning it will slowly deform over time.

For high-load structural applications, filled grades of PTFE (which include additives like glass, carbon, or bronze) are often used to improve strength and resistance to deformation.

Poor Bonding Properties

The same non-stick quality that prevents contamination also makes PTFE extremely difficult to bond using conventional adhesives. Its surface must be chemically etched or specially treated to allow for adhesion to other materials.

Lower Wear Resistance (in Pure Form)

While its friction is low, pure PTFE can wear more quickly than harder plastics or metals in abrasive conditions. As with mechanical strength, wear resistance is significantly improved in filled PTFE composites.

Selecting PTFE for Your Application

Choosing the right material depends entirely on the primary demands of your project.

- If your primary focus is performance in corrosive or extreme temperature environments: PTFE is an almost unrivaled choice due to its chemical and thermal stability.

- If your primary focus is smooth, quiet, and maintenance-free motion: PTFE's self-lubricating properties and low-friction coefficient make it an ideal candidate.

- If your primary focus is high-load mechanical support: You must carefully evaluate if pure PTFE is sufficient, or if a filled PTFE composite or an entirely different material is required to prevent deformation.

Ultimately, understanding both the remarkable strengths and the distinct limitations of PTFE is the key to successful engineering.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Friction | Extremely low coefficient | Self-lubricating, smooth motion, no stick-slip |

| Temperature Range | -200°C to +260°C | Reliable performance from cryogenic to high-heat |

| Chemical Resistance | Inert to most chemicals & solvents | Longevity and stability in corrosive environments |

| Electrical Property | Excellent insulator | Prevents electrical flow between components |

| Limitation (Pure PTFE) | Prone to cold flow under load | Requires careful design; filled grades improve strength |

Need a PTFE Bushing Solution for Your Demanding Application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom bushings, for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between PTFE's superior properties and its mechanical limitations.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your operational environment, whether you need pure PTFE for maximum chemical resistance or a filled composite for enhanced strength and wear resistance.

Contact KINTEK today to discuss your project requirements and let our precision engineering deliver the performance and reliability you need.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support