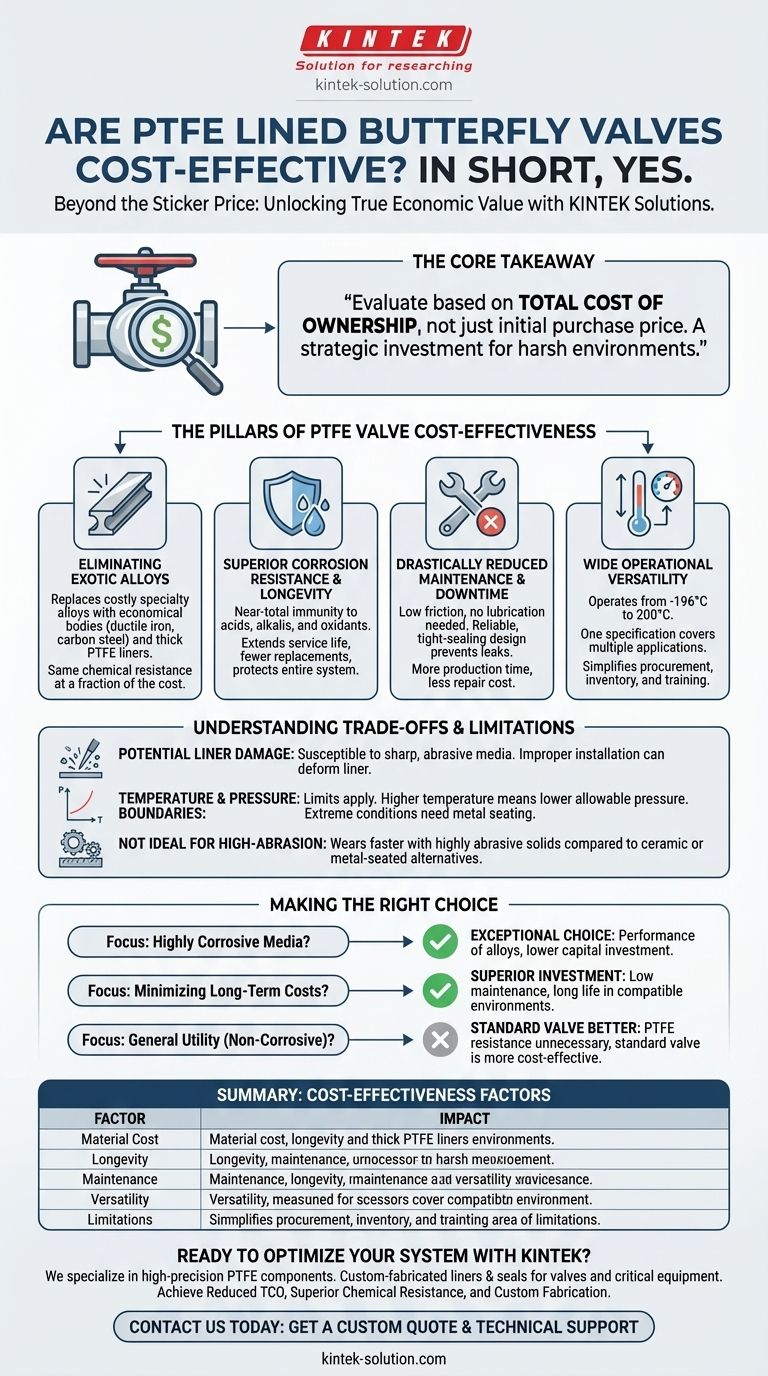

In short, yes. PTFE lined butterfly valves are a highly cost-effective solution, but their true economic value is not in the initial purchase price. Their cost-effectiveness comes from their ability to deliver the performance of expensive specialty alloy valves in corrosive applications, combined with a significant reduction in long-term maintenance and replacement costs.

The core takeaway is that you should evaluate PTFE lined butterfly valves based on their total cost of ownership, not just their sticker price. They represent a strategic investment to control costs in harsh industrial environments where standard valves would quickly fail.

Beyond the Price Tag: The Pillars of PTFE Valve Cost-Effectiveness

To understand the financial case for these valves, we must look at how their specific engineering solves expensive operational problems. Their value is built on replacing more costly alternatives and minimizing ongoing expenses.

Eliminating the Need for Exotic Alloys

A primary driver of cost is the material required to resist corrosive media. A valve made entirely of a specialty alloy like Hastelloy can be prohibitively expensive.

PTFE lining allows for a more economical valve body, such as ductile iron or carbon steel, to be used. The thick, inert PTFE liner provides the necessary chemical resistance, offering a similar performance profile to an exotic alloy valve at a fraction of the cost.

Superior Corrosion Resistance and Longevity

Constant replacement of failed equipment is a major hidden cost in any industrial process. PTFE's near-total immunity to strong acids, alkalis, and oxidants directly translates to a longer service life.

This extended lifespan means fewer valve replacements over time. It also protects other metal components in the system from chemical attack, preventing cascading failures and reducing overall plant maintenance costs.

Drastically Reduced Maintenance and Downtime

PTFE has an extremely low coefficient of friction, which means the valve disc can turn easily without requiring lubrication. This eliminates a recurring maintenance task.

Furthermore, their reliable, tight-sealing design prevents leaks, which are a source of product loss, safety hazards, and environmental compliance issues. Less downtime for repairs or clean-ups means more production time and higher output.

Wide Operational Versatility

These valves operate effectively across an impressive temperature range, typically from cryogenic temperatures (-196°C) up to 200°C.

This versatility allows a single valve specification to cover numerous applications within a facility. This simplifies procurement, reduces the need to stock multiple types of spare parts, and streamlines maintenance training.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. An objective assessment requires acknowledging their limitations to avoid costly misapplication.

Potential for Liner Damage

The PTFE liner, while durable, is not as mechanically robust as a solid metal body. It can be susceptible to damage from sharp, abrasive particles in the media, such as in heavy slurries.

Improper installation, particularly over-tightening flange bolts, can also deform or damage the liner, leading to premature failure.

Temperature and Pressure Boundaries

Every valve operates within a pressure-temperature (P-T) curve. While the operational range of PTFE is wide, it has firm limits.

As temperatures increase, the maximum allowable pressure for a PTFE lined valve decreases. In applications exceeding these limits, a metal-seated valve is the necessary, albeit more expensive, choice.

Not Ideal for High-Abrasion Service

For media containing highly abrasive solids, a PTFE liner can wear down more quickly than specialized alternatives like ceramic or metal-seated valves designed for slurry service. The cost-effectiveness diminishes if the valve requires frequent replacement due to abrasive wear.

Making the Right Choice for Your Application

To determine if a PTFE lined valve is the right financial decision for you, analyze your primary operational goal.

- If your primary focus is handling highly corrosive media: These valves are an exceptional choice, offering the performance of exotic alloys for a significantly lower capital investment.

- If your primary focus is minimizing long-term operational costs: The low maintenance requirements and long service life in compatible environments make them a superior long-term investment.

- If your primary focus is general utility service with non-corrosive media: A standard, unlined butterfly valve is almost always the more cost-effective option, as the advanced chemical resistance of PTFE is unnecessary.

Ultimately, viewing the valve as a long-term asset for managing challenging conditions, rather than just an upfront expense, is the key to unlocking its true economic value.

Summary Table:

| Factor | Impact on Cost-Effectiveness |

|---|---|

| Material Cost | Replaces expensive exotic alloys with a cost-effective body and PTFE liner. |

| Longevity | Near-total chemical resistance leads to a longer service life and fewer replacements. |

| Maintenance | Low friction eliminates lubrication needs; tight-sealing design prevents leaks. |

| Versatility | Wide temperature range (-196°C to 200°C) simplifies procurement and inventory. |

| Limitations | Not ideal for highly abrasive slurries or extreme pressure/temperature conditions. |

Ready to optimize your fluid handling system's performance and cost?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated liners and seals for valves and other critical equipment. Our expertise ensures you get a solution perfectly tailored to the demands of the semiconductor, medical, laboratory, and industrial sectors.

We help you achieve:

- Reduced Total Cost of Ownership: Our durable PTFE components extend equipment life and minimize maintenance.

- Superior Chemical Resistance: Protect your systems from even the most aggressive media.

- Custom Fabrication: From prototypes to high-volume orders, we deliver the exact specifications you need.

Contact us today via the form below to discuss your application and discover how our PTFE solutions can enhance your operational efficiency and bottom line. Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials