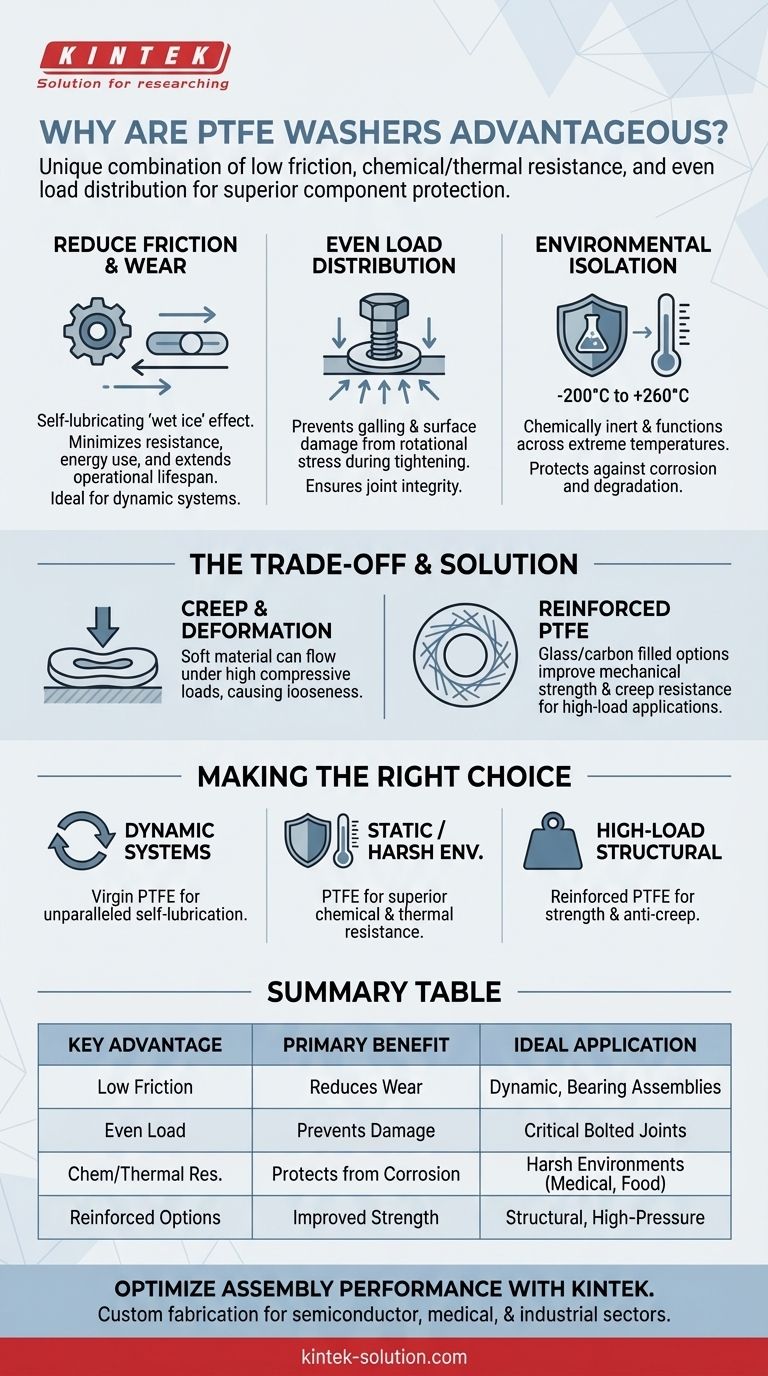

In short, PTFE washers are advantageous for their unique combination of an extremely low-friction surface, exceptional chemical and thermal resistance, and their ability to evenly distribute clamping loads. This allows them to protect mating surfaces, reduce operational wear, and ensure joint integrity in environments where traditional metal washers would fail.

The core value of a PTFE washer is not just in being a spacer, but in acting as a self-lubricating, protective barrier. It simultaneously isolates components from rotational stress during tightening and from harsh environmental conditions during operation.

The Core Functions of a PTFE Washer

To understand why PTFE (polytetrafluoroethylene) is so effective, it's best to break down its primary functions within a mechanical assembly. Each property solves a distinct engineering challenge.

Reducing Friction and Wear

The most well-known property of PTFE is its extremely low coefficient of friction. This makes its surface incredibly slippery, almost like wet ice.

In mechanical systems, this self-lubricating nature is a significant advantage. It allows moving or rotating parts, such as those in bearing assemblies, to operate with minimal resistance.

This directly translates to reduced wear and tear on contact surfaces, lower energy consumption, and an extended operational lifespan for the entire assembly. It is particularly valuable where external lubricants are impractical or could cause contamination, such as in food processing or medical equipment.

Ensuring Even Load Distribution

When you tighten a bolt or screw, a significant amount of rotational force (torque) is generated. A standard metal washer can transfer this twisting stress directly to the underlying component surface.

This can cause galling, scratching, or other damage, compromising the surface finish and the integrity of the joint.

PTFE washers create a low-friction barrier between the bolt head and the component. This allows the fastener to turn and achieve its proper clamping force without transferring damaging rotational stress to the surface below, ensuring a clean and even distribution of the load.

Providing Environmental Isolation

Beyond its mechanical properties, PTFE is a highly inert polymer. It offers exceptional resistance to a vast range of chemicals, acids, and solvents.

It also performs reliably across an extreme temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows PTFE washers to function as effective seals and isolators in harsh chemical or high-temperature environments, protecting the joint from corrosion and degradation where metal washers would quickly fail.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its primary limitation stems from one of its core material properties.

The Challenge of Material Softness

Compared to metals, PTFE is a relatively soft material. Under very high compressive loads, it can be prone to deformation or "creep," where the material slowly flows out from under the load over time.

This can lead to a loss of preload in critical bolted joints, potentially causing the assembly to loosen.

The Solution: Reinforced PTFE

To counteract this, manufacturers offer reinforced or filled PTFE washers. By adding fillers like glass fiber or carbon, the material's mechanical strength and resistance to creep are dramatically improved.

These composite washers retain the desirable low-friction and chemical resistance of PTFE while providing the compressive strength needed for more demanding, high-load applications.

Making the Right Choice for Your Assembly

Selecting the right washer depends entirely on the specific demands of your application.

- If your primary focus is dynamic systems with moving parts: Choose a virgin PTFE washer for its unparalleled self-lubricating properties to minimize wear and energy use.

- If your primary focus is static joints in harsh environments: Use a PTFE washer for its superior chemical and thermal resistance, which will protect the integrity of the fastener and joint.

- If your primary focus is high-load structural applications: Specify a glass- or carbon-filled PTFE washer to prevent material creep and ensure long-term clamping force.

Ultimately, a PTFE washer is an engineering tool designed to solve problems of friction, corrosion, and surface damage that other materials cannot.

Summary Table:

| Key Advantage | Primary Benefit | Ideal Application |

|---|---|---|

| Low Friction & Self-Lubricating | Reduces wear, lowers energy use | Dynamic systems, bearing assemblies |

| Even Load Distribution | Prevents surface damage, ensures joint integrity | Critical bolted joints, precision equipment |

| Chemical & Thermal Resistance | Protects against corrosion, functions from -200°C to +260°C | Harsh environments (chemical, medical, food processing) |

| Reinforced Options Available | Improved strength & creep resistance for high-load applications | Structural applications, high-pressure systems |

Optimize your assembly's performance and longevity with precision-engineered PTFE washers from KINTEK.

Whether your application is in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom PTFE fabrication ensures you get the perfect component—from prototypes to high-volume orders. We prioritize precision production to deliver seals, liners, labware, and washers that meet your exact specifications.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications