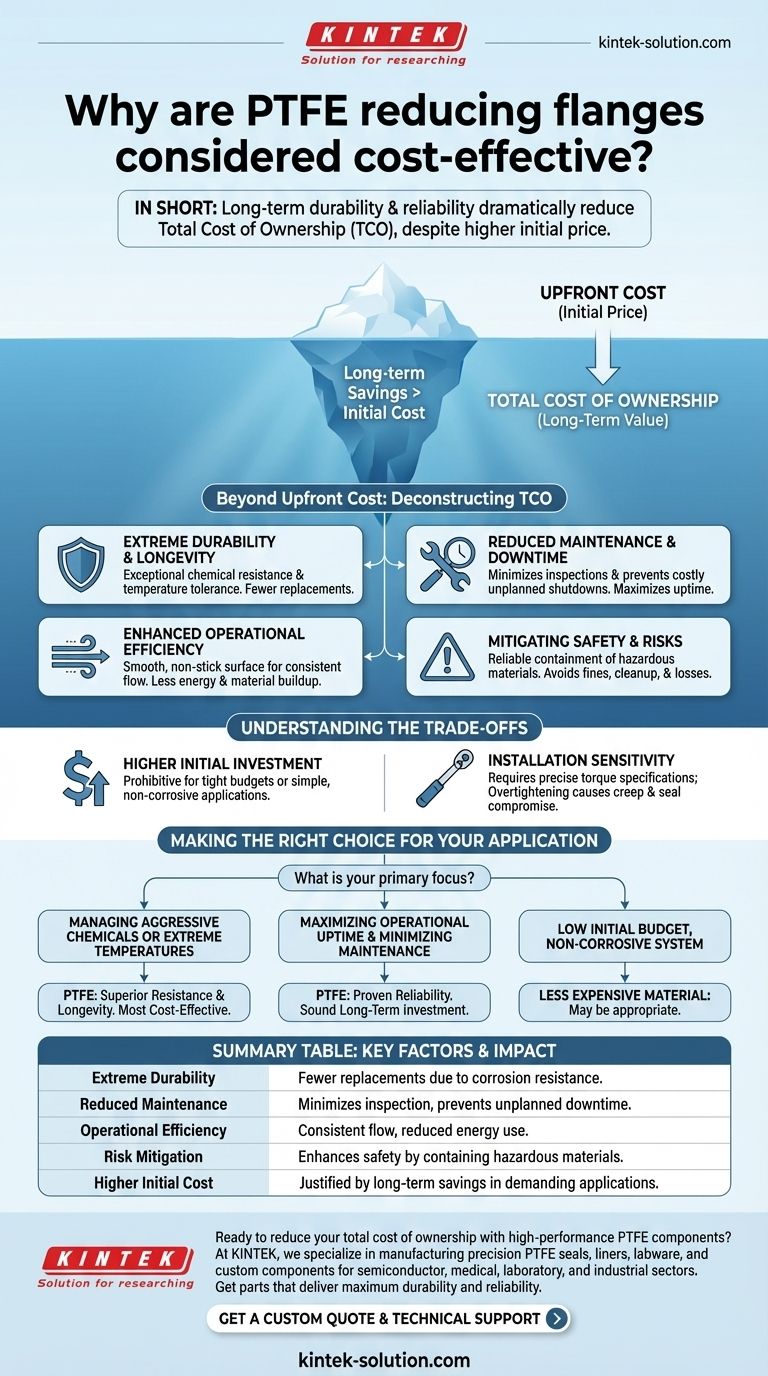

In short, PTFE reducing flanges are considered cost-effective because their long-term durability and reliability dramatically reduce the total cost of ownership. While their initial purchase price is often higher than that of other materials, they provide significant savings over the life of a piping system by minimizing the need for replacement, maintenance, and costly operational downtime.

The decision to use PTFE reducing flanges is an exercise in evaluating total cost of ownership, not just upfront price. Their value is realized through superior performance in demanding environments, which prevents the cascading costs of component failure, maintenance, and lost productivity.

Beyond Upfront Cost: Deconstructing Total Cost of Ownership

To understand the cost-effectiveness of PTFE, you must look beyond the initial invoice. The true financial impact of a component is measured over its entire operational life, especially within critical industrial processes.

Extreme Durability and Longevity

PTFE's material properties are the primary driver of its long-term value. It exhibits exceptional chemical resistance, meaning it will not corrode, degrade, or become brittle when exposed to aggressive acids, bases, or solvents.

This resilience, combined with its tolerance for a wide range of temperatures, means the flange will not fail prematurely. This directly translates to fewer replacements over the system's lifespan.

Reduced Maintenance and Downtime

A failed flange doesn't just cost the price of a replacement part; it forces a system shutdown. Unplanned downtime is often the single largest cost associated with component failure.

Because PTFE resists chemical attack and degradation, the need for frequent inspection and preventative maintenance is significantly reduced. This reliability allows for more predictable maintenance schedules and, more importantly, maximizes operational uptime.

Enhanced Operational Efficiency

PTFE has an extremely smooth, non-stick surface. In a piping system, this property is crucial for maintaining consistent and efficient flow.

Less friction means less energy is required to move fluid through the system. Furthermore, the non-stick quality helps prevent the buildup of process materials, which could otherwise restrict flow, reduce output, and diminish overall process productivity.

Mitigating Safety and Environmental Risks

In systems handling hazardous materials, a leak is not just an operational problem—it's a critical safety and environmental incident.

The reliability of a PTFE flange in containing corrosive substances enhances plant safety. This mitigates the immense financial risks associated with leaks, which can include cleanup costs, regulatory fines, and production losses.

Understanding the Trade-offs

No material is a perfect solution for every scenario. Acknowledging the trade-offs is key to making an informed decision.

The Higher Initial Investment

The most significant factor working against PTFE is its higher upfront cost compared to standard metal or other polymer flanges. For projects with extremely tight initial capital budgets, this can be a prohibitive barrier.

This higher cost means PTFE is often unjustifiable for simple, non-corrosive applications like basic water transport, where a cheaper material would suffice.

Installation Sensitivity

While installation is straightforward, PTFE is a softer material than metal. Proper torque specifications must be followed precisely during installation to create a reliable seal without damaging the flange.

Overtightening can cause the material to "creep" or deform, compromising the seal and negating its long-term benefits. This requires well-trained installation personnel.

Making the Right Choice for Your Application

Ultimately, the cost-effectiveness of a PTFE reducing flange is entirely dependent on the specific demands of your system.

- If your primary focus is managing aggressive chemicals or extreme temperatures: PTFE is almost certainly the most cost-effective choice due to its superior material resistance and longevity.

- If your primary focus is maximizing operational uptime and minimizing maintenance: The proven reliability of PTFE significantly reduces the risk of costly unplanned shutdowns, making it a sound long-term investment.

- If your primary focus is a low initial project budget for a non-corrosive system: A less expensive material may be more appropriate, as the advanced properties of PTFE would be underutilized.

By evaluating your needs against the total cost of ownership, you can determine if the long-term benefits of PTFE justify its initial investment.

Summary Table:

| Key Factor | Impact on Cost-Effectiveness |

|---|---|

| Extreme Durability | Resists corrosion and degradation, leading to fewer replacements. |

| Reduced Maintenance | Minimizes inspection needs and prevents unplanned downtime. |

| Operational Efficiency | Non-stick surface ensures consistent flow and reduces energy use. |

| Risk Mitigation | Enhances safety by reliably containing hazardous materials. |

| Higher Initial Cost | Justified by long-term savings in demanding applications. |

Ready to reduce your total cost of ownership with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get parts that deliver maximum durability and reliability, protecting your operations from costly downtime.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific application challenges. Contact us today to discuss how our PTFE solutions can enhance your system's efficiency and profitability.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Which chemicals react negatively with PTFE? Identify the Few Substances That Can Compromise Its Integrity

- What are the primary functions of washers in mechanical assemblies? Ensure Joint Reliability & Prevent Damage

- What are PTFE expansion joints and what is their primary function? Protect Your Piping System from Stress and Failure

- How do spiral and split PTFE backup rings compare in terms of sealing performance? High-Pressure vs. Easy Installation

- What are the longevity and durability benefits of PTFE gaskets? Achieve Reliable, Long-Lasting Sealing Performance

- In which industries is porous PTFE applied? Solve Harsh Environment Challenges with KINTEK

- Why are PTFE gaskets considered a preferred sealing solution? Ensure Reliability in Demanding Environments

- What are some common applications of PTFE balls? Essential Uses in Chemical & Low-Friction Systems