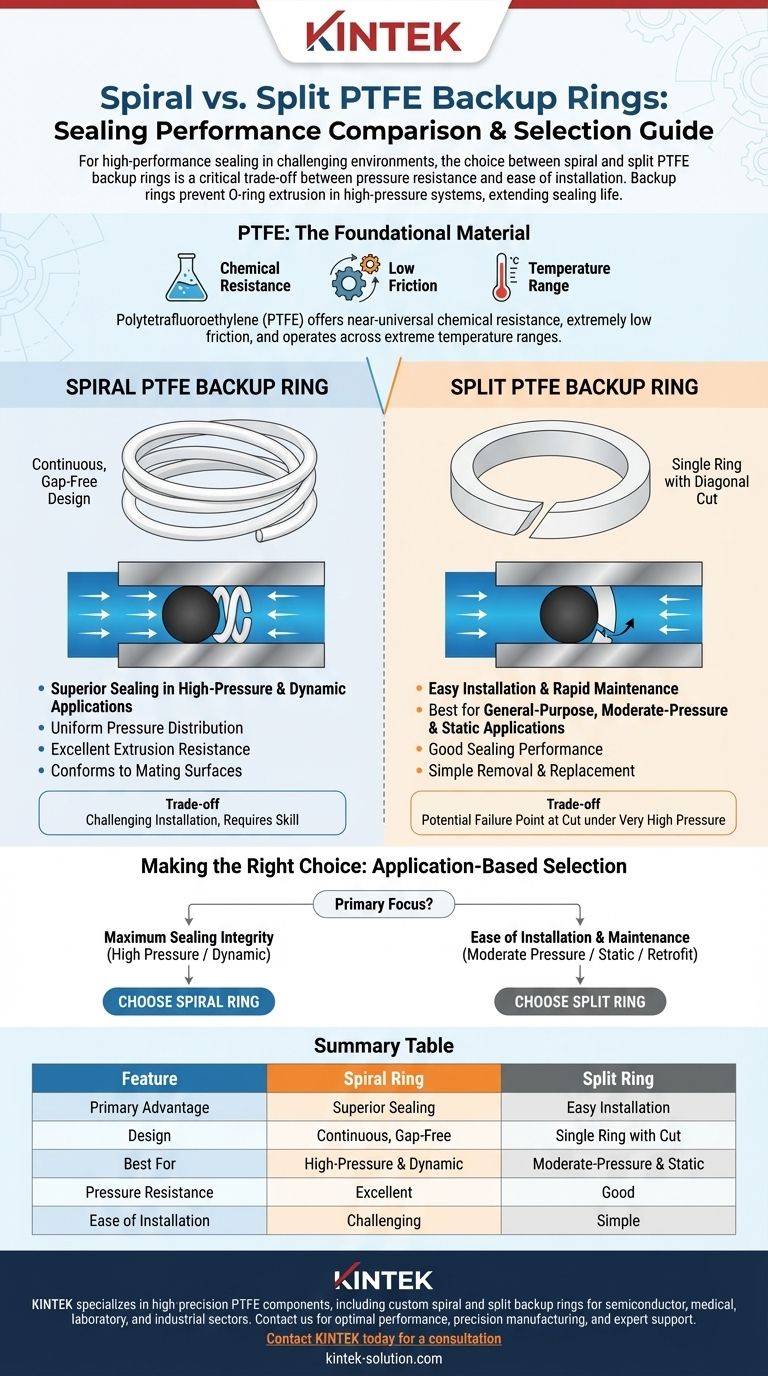

For high-performance sealing, the choice between a spiral and a split PTFE backup ring comes down to a critical trade-off between pressure resistance and ease of installation. Spiral PTFE backup rings provide superior sealing in high-pressure and dynamic applications due to their continuous, gap-free design. Split rings, while offering good performance, are best suited for general-purpose, moderate-pressure situations where installation convenience is a key factor.

The core difference is simple: a spiral ring creates a continuous barrier against O-ring extrusion, making it ideal for demanding environments. A split ring intentionally introduces a gap for easy installation, which can become a potential failure point under very high pressure.

The Foundational Role of PTFE in Sealing

Before comparing the ring types, it's essential to understand why Polytetrafluoroethylene (PTFE) is the material of choice for these components. Its properties make it uniquely suited for challenging sealing environments.

Why PTFE is a Superior Sealing Material

PTFE offers an exceptional combination of characteristics. It has near-universal chemical resistance, an extremely low coefficient of friction, and can operate across a vast temperature range (typically -200°C to +260°C).

These properties ensure the backup ring will not degrade from chemical exposure, will not cause excess friction in dynamic seals, and will maintain its integrity in extreme thermal conditions.

The Purpose of a Backup Ring

A backup ring is not the primary seal. Its job is to support a softer elastomeric seal, like an O-ring, in high-pressure applications.

By sitting in the gland behind the O-ring, it prevents the O-ring from being forced, or extruded, into the clearance gap between moving parts. This extends the life and pressure rating of the entire sealing system.

A Head-to-Head Comparison: Spiral vs. Split

The functional differences between spiral and split rings stem directly from their physical construction.

Design and Construction

A spiral backup ring is constructed from a continuous coil of PTFE wound into a helical shape, typically with two turns. It has no cuts or gaps along its sealing surface.

A split backup ring is a single solid ring with one diagonal cut (a "scarf cut") through its cross-section. This cut allows the ring to be temporarily expanded for installation.

Sealing Mechanism and Performance

The spiral ring's continuous, gap-free design provides uniform pressure distribution along the entire circumference of the O-ring it supports. This seamless barrier is highly effective at preventing extrusion.

The split ring's performance is limited by its cut. While the cut is angled to minimize the gap, it still represents a potential path for the O-ring to extrude through under extreme pressure.

Pressure and Dynamic Capabilities

Because of its seamless construction, the spiral ring is the definitive choice for very high-pressure systems. Its flexibility also allows it to conform perfectly to mating surfaces during dynamic motion, making it ideal for hydraulic cylinders and other moving components.

The split ring is perfectly suitable for moderate pressures and is most effective in static applications where there is no movement between the sealed parts.

Understanding the Practical Trade-offs

The superior sealing performance of a spiral ring comes at a cost, primarily in the complexity of its installation.

Installation and Accessibility

This is the split ring's greatest advantage. The cut allows it to be easily opened and snapped into a groove without significant deformation. This is especially valuable in designs with limited accessibility.

Installing a spiral ring can be challenging. It must be carefully stretched or "wound" over components and into the gland, which requires skill and carries a risk of damaging the ring if done improperly.

Maintenance and Replacement

The ease of installing a split ring directly translates to faster and simpler maintenance. A technician can quickly remove and replace the ring with minimal disassembly of surrounding components.

Replacing a spiral ring can be a more involved process, often requiring more extensive disassembly to gain the access needed to properly install the new ring.

Making the Right Choice for Your Application

Your final decision should be guided by a clear analysis of your system's operational demands and maintenance strategy.

- If your primary focus is maximum sealing integrity under high pressure or dynamic motion: Choose a spiral backup ring for its superior, gap-free extrusion resistance.

- If your primary focus is ease of installation and rapid maintenance: Choose a split backup ring, especially for static or moderate-pressure applications where accessibility is a concern.

- If you are retrofitting or performing a field repair: A split ring is often the more practical choice due to its simpler installation requirements.

By matching the ring's design to the application's specific pressures and serviceability needs, you ensure both long-term system reliability and operational efficiency.

Summary Table:

| Feature | Spiral PTFE Backup Ring | Split PTFE Backup Ring |

|---|---|---|

| Primary Advantage | Superior sealing, high-pressure resistance | Easy installation, maintenance convenience |

| Design | Continuous, gap-free spiral | Single ring with a diagonal cut (scarf cut) |

| Best For | High-pressure & dynamic applications (e.g., hydraulic cylinders) | Moderate-pressure & static applications |

| Pressure Resistance | Excellent | Good |

| Ease of Installation | Challenging, requires skill | Simple and quick |

Need the right PTFE backup ring for your specific pressure and installation requirements?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom spiral and split backup rings. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, we provide the ideal sealing solution—from prototypes to high-volume orders.

We ensure:

- Optimal Performance: The right ring type for your pressure and dynamic needs.

- Precision Manufacturing: Consistent quality and reliability.

- Expert Support: Guidance to select the best component for your system.

Contact KINTEK today for a consultation and let our expertise enhance your sealing system's reliability and efficiency.

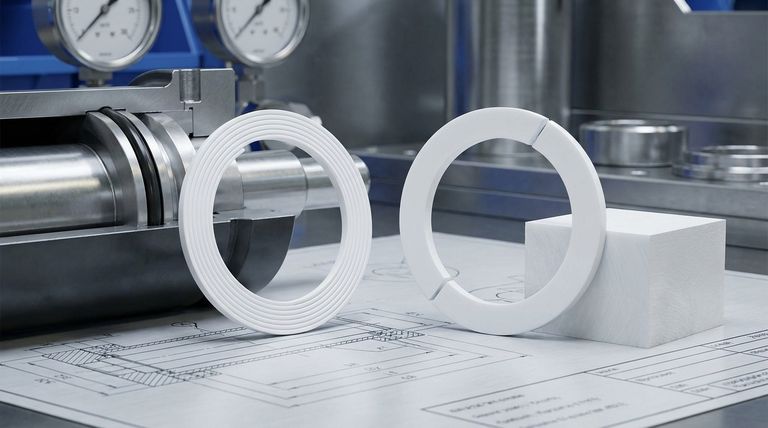

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications