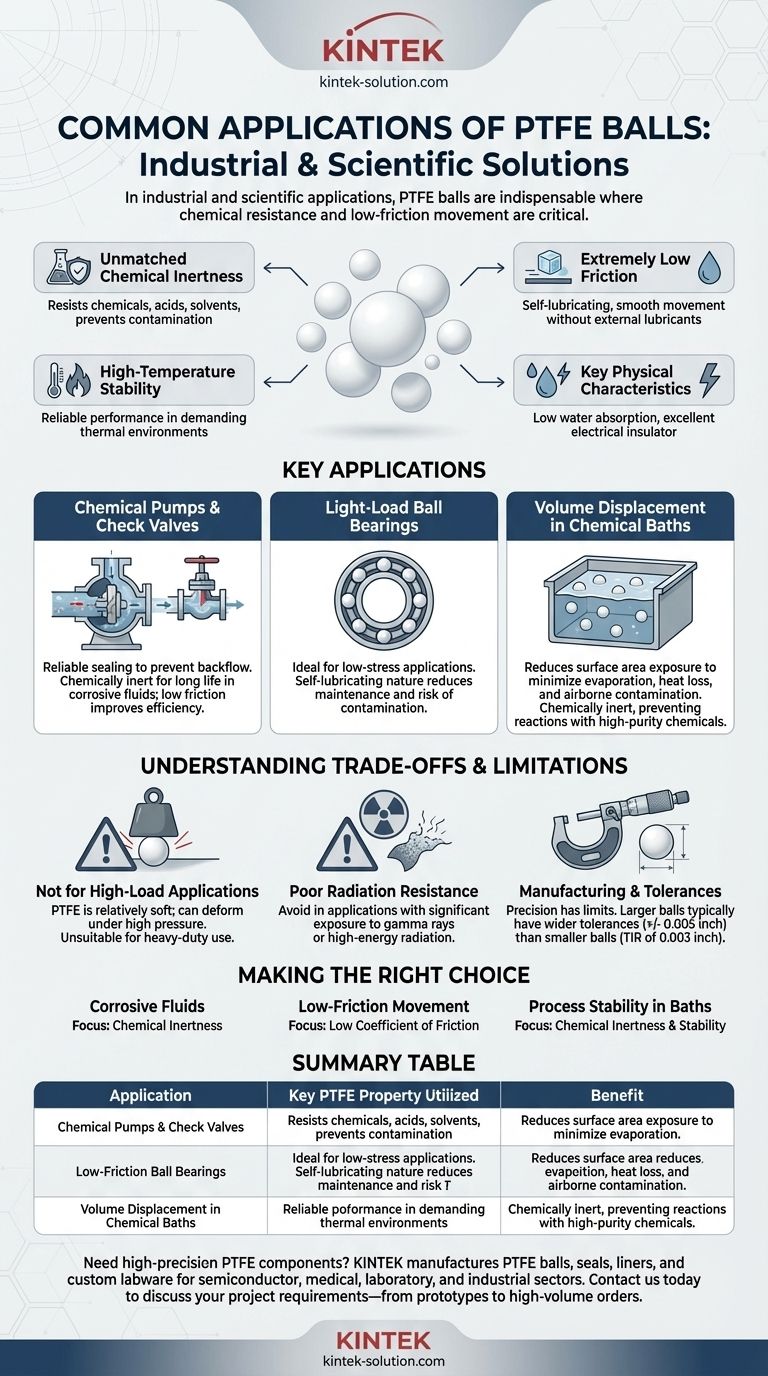

In industrial and scientific applications, PTFE balls are most commonly used in chemical handling pumps, check valves, light-load ball bearings, and as volume displacement media in chemical baths. Their unique material properties make them an indispensable component where chemical resistance and low-friction movement are critical.

The core reason for selecting PTFE balls is their unparalleled combination of chemical inertness and an extremely low coefficient of friction. This makes them ideal for applications involving corrosive fluids or where self-lubrication is a primary design requirement.

The Core Properties Driving PTFE Applications

To understand where PTFE balls excel, we must first look at the fundamental properties of the material itself, Polytetrafluoroethylene. These characteristics directly dictate its most effective uses.

Unmatched Chemical Inertness

The molecular structure of PTFE features incredibly strong carbon-fluorine bonds. This makes the material resistant to nearly all industrial chemicals, acids, and solvents, preventing degradation or contamination.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent lubricity means components can move freely without the need for external lubricants.

High-Temperature Stability

This material maintains its integrity across a wide range of temperatures. It can perform reliably in demanding thermal environments common in industrial processes.

Key Physical Characteristics

PTFE exhibits very low water absorption (around 0.01%), making it stable in moist environments. It also serves as an excellent electrical insulator.

A Closer Look at Key Applications

These fundamental properties translate directly into specific, high-value applications where other materials would quickly fail.

Chemical Pumps and Check Valves

In a check valve, a PTFE ball creates a reliable seal that prevents backflow. Because it is chemically inert, the ball will not swell, soften, or degrade when in constant contact with aggressive fluids, ensuring a long service life and system integrity.

Its low-friction surface allows the ball to move and seal with minimal pressure, improving the valve's efficiency and responsiveness.

Light-Load Ball Bearings

For applications that do not involve heavy mechanical stress, PTFE balls are ideal. Their self-lubricating nature simplifies bearing design, reduces maintenance, and eliminates the risk of contamination from grease or oil.

Volume Displacement in Chemical Baths

Floating a layer of PTFE balls on the surface of a chemical bath serves a critical function. It reduces the liquid's surface area exposed to the air, which minimizes evaporation, cuts heat loss, and prevents airborne contaminants from entering the solution.

The balls' chemical inertness is paramount here, as they will not react with or contaminate the high-purity chemicals in the bath.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Not for High-Load Applications

PTFE is a relatively soft material. Under high mechanical loads, it can deform or "creep," making it unsuitable for heavy-duty bearings or high-pressure structural components. The term "light-load" is a critical distinction.

Poor Radiation Resistance

As noted in its material data, PTFE has poor resistance to radiation. It should not be used in applications with significant exposure to gamma rays or other high-energy radiation, as this will degrade the material's structure.

Manufacturing and Tolerances

Precision is achievable but has limits. While smaller PTFE balls can be manufactured to tight tolerances (TIR of 0.003 inch), larger balls typically have a wider tolerance (around +/- 0.005 inch), which must be factored into engineering designs.

Making the Right Choice for Your Goal

Your specific goal determines whether PTFE is the correct material choice.

- If your primary focus is handling corrosive fluids: PTFE's chemical inertness makes it the superior choice for seals, valve components, and pumps to ensure longevity and prevent contamination.

- If your primary focus is low-friction movement without lubricants: PTFE is ideal for light-load bearings and control valves where smooth, effortless motion is essential.

- If your primary focus is process stability in chemical baths: Use PTFE balls as a floating cover to reduce evaporation and heat loss without risk of chemical reaction.

Ultimately, PTFE balls are the definitive solution when chemical resistance and inherent lubricity are the most critical performance factors for a component.

Summary Table:

| Application | Key PTFE Property Utilized | Benefit |

|---|---|---|

| Chemical Pumps & Valves | Chemical Inertness | Resists corrosion, ensures long service life |

| Light-Load Bearings | Low Coefficient of Friction | Self-lubricating, reduces maintenance |

| Volume Displacement in Baths | Chemical Inertness & Stability | Minimizes evaporation, prevents contamination |

Need high-precision PTFE components for your specialized application? KINTEK manufactures PTFE balls, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures reliable performance in corrosive or low-friction environments. Contact us today to discuss your project requirements—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits