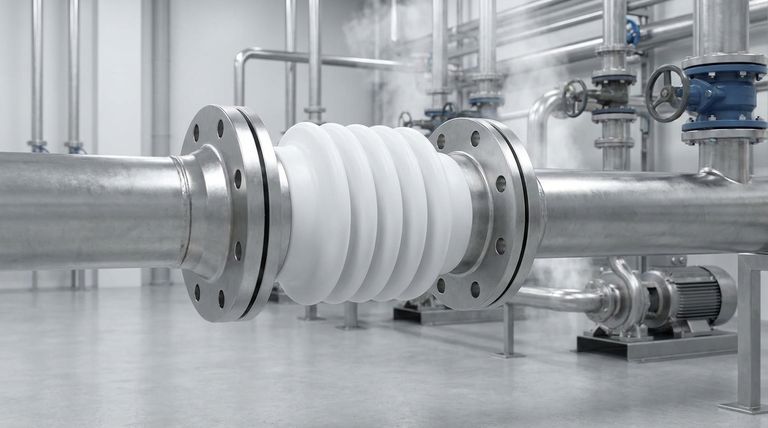

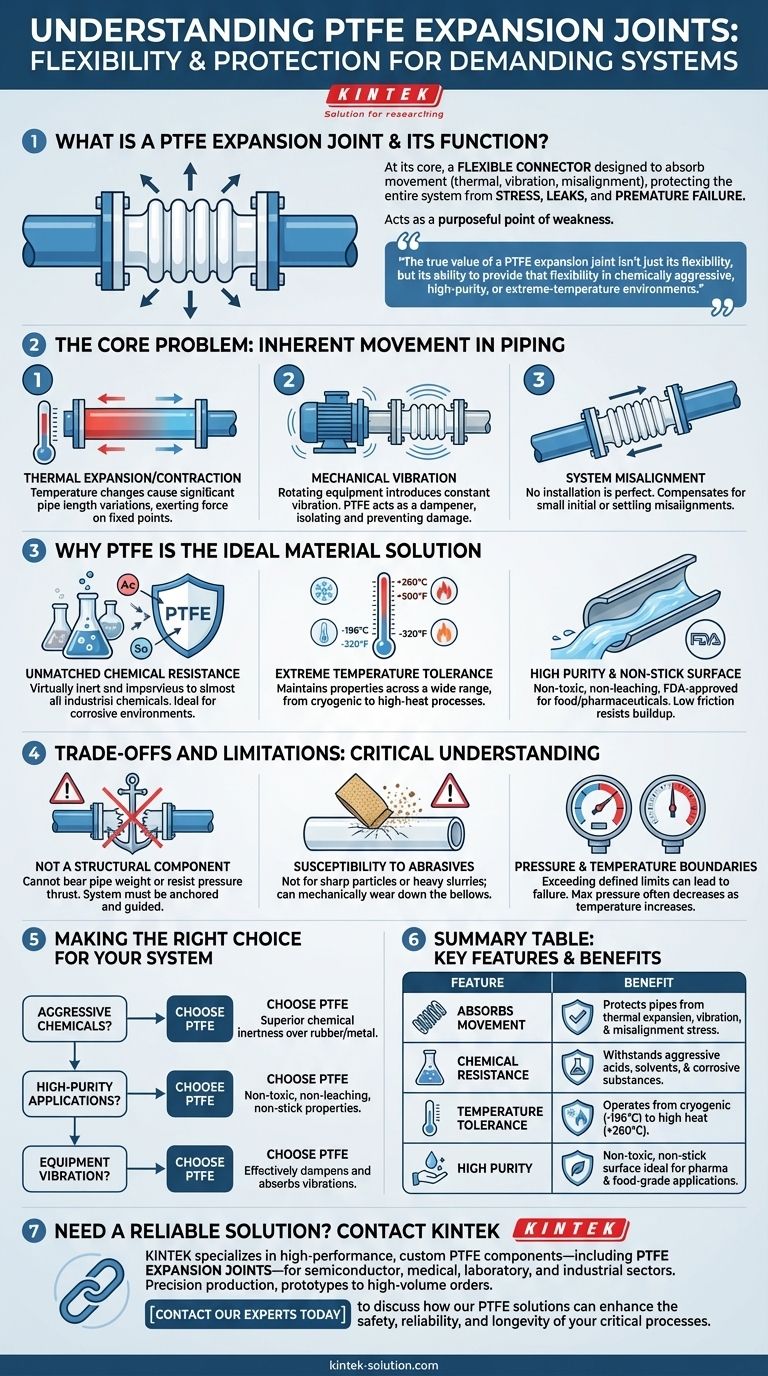

At its core, a PTFE expansion joint is a flexible connector designed to be the point of purposeful weakness within a rigid piping system. Its primary function is to absorb movement—such as thermal expansion and contraction, mechanical vibrations, and slight misalignments—thereby protecting the integrity of the entire system from stress, leaks, and premature failure.

The true value of a PTFE expansion joint isn't just its flexibility, but its ability to provide that flexibility in chemically aggressive, high-purity, or extreme-temperature environments where metal or rubber alternatives would corrode and fail.

The Core Problem: Inherent Movement in Piping Systems

Industrial piping may look static, but it is in a constant state of subtle movement. Unmanaged, this movement concentrates stress at the weakest points, leading to catastrophic failure. Expansion joints are engineered to absorb these forces safely.

Thermal Expansion and Contraction

As process fluids or ambient temperatures change, pipes expand when heated and shrink when cooled. Over a long pipe run, this change in length can be significant, exerting immense force on fixed points like nozzles and flanges.

Mechanical Vibration

Pumps, compressors, and other rotating equipment introduce constant vibration into a piping system. A PTFE expansion joint acts as a dampener, isolating this vibrational energy and preventing it from propagating down the pipeline and damaging sensitive equipment.

System Misalignment

No installation is perfect. Small, unavoidable misalignments between two pieces of equipment or pipe runs can create significant residual stress. An expansion joint compensates for this initial or settling misalignment.

Why PTFE is the Ideal Material Solution

The choice of Polytetrafluoroethylene (PTFE) is deliberate. Its unique molecular properties make it exceptionally suited for creating a durable, flexible seal in the most demanding industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert and impervious to almost all industrial chemicals, acids, and solvents. This makes it the default material for systems in chemical processing, pharmaceuticals, and other industries handling corrosive substances.

Extreme Temperature Tolerance

PTFE maintains its properties across an exceptionally wide temperature range, typically from -196°C to +260°C (-320°F to +500°F). It can handle cryogenic applications and high-temperature processes without becoming brittle or degrading.

High Purity and Non-Stick Surface

The material is non-toxic, does not leach contaminants, and is often FDA-approved for food and pharmaceutical contact. Its famously low coefficient of friction creates a non-stick surface that resists material buildup, ensuring clean and efficient flow.

Understanding the Trade-offs and Limitations

While powerful, PTFE expansion joints are not a universal solution. Understanding their limitations is critical for proper application and system safety.

Not a Structural Component

An expansion joint is designed exclusively to absorb movement and vibration. It cannot bear the weight of the pipe or resist the internal pressure thrust. The piping system must still be properly anchored and guided to direct movement into the joint.

Susceptibility to Abrasives

While chemically robust, PTFE is a relatively soft material. It is not recommended for services containing sharp, abrasive particles or heavy slurries, which can mechanically wear down the flexible bellows over time.

Pressure and Temperature Boundaries

Every expansion joint has a defined pressure and temperature limit. Exceeding these specifications can lead to failure. The maximum allowable pressure often decreases as the operating temperature increases.

Making the Right Choice for Your System

Selecting the correct component requires matching the material's strengths to the system's primary challenge.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness makes it the superior choice over rubber or metal joints that would corrode.

- If your primary focus is high-purity applications: PTFE's non-toxic, non-leaching, and non-stick properties ensure the integrity of food-grade or pharmaceutical products.

- If your primary focus is isolating equipment vibration: A PTFE expansion joint effectively dampens and absorbs vibrations from pumps and motors, protecting the wider piping network.

By understanding these principles, you can confidently specify the right component to ensure the long-term safety and reliability of your entire piping system.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Absorbs Movement | Protects pipes from thermal expansion, vibration, and misalignment stress. |

| Chemical Resistance | Withstands aggressive acids, solvents, and corrosive substances. |

| Temperature Tolerance | Operates from cryogenic (-196°C) to high heat (+260°C). |

| High Purity | Non-toxic, non-stick surface ideal for pharmaceutical and food-grade applications. |

Need a reliable solution for your demanding piping system?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and PTFE expansion joints—for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance the safety, reliability, and longevity of your critical processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability