PTFE gaskets are a preferred sealing solution in demanding environments because of their unique combination of near-total chemical inertness, an exceptionally wide operating temperature range, and remarkable mechanical conformability. These properties ensure a reliable, long-lasting seal where other materials would quickly degrade or fail, making them indispensable in critical industrial applications.

The true value of PTFE is not just its resistance to harsh conditions, but its ability to physically adapt to imperfect sealing surfaces. This combination of chemical, thermal, and mechanical resilience is what provides an unparalleled level of sealing integrity.

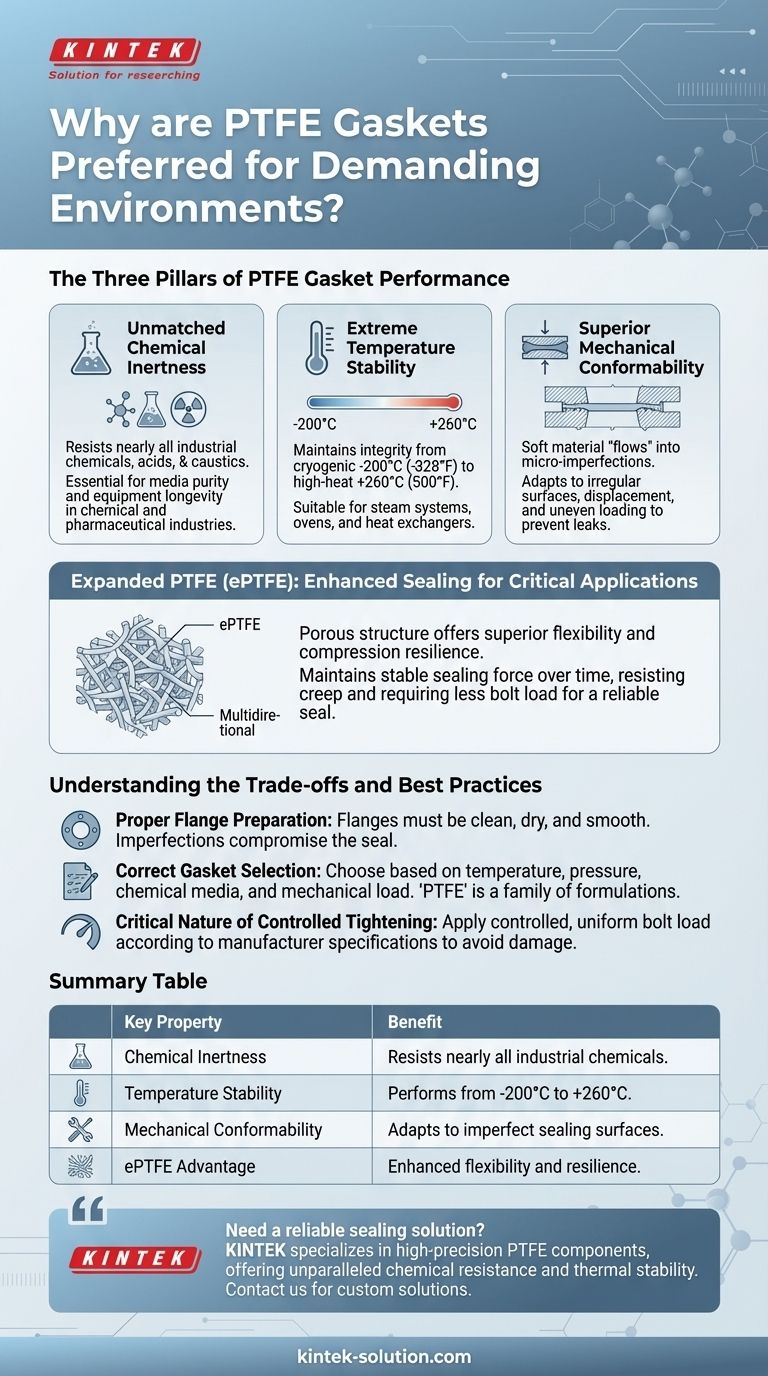

The Three Pillars of PTFE Gasket Performance

To understand why PTFE is so trusted, we must examine its core characteristics. These three properties work in concert to create a robust and reliable seal.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This makes it an essential material in industries where media purity and equipment longevity are paramount.

This level of chemical resistance is critical in chemical processing, pharmaceutical manufacturing, and electronics, where corrosive substances would rapidly destroy conventional gasket materials.

Extreme Temperature Stability

PTFE gaskets maintain their integrity and sealing properties across an exceptionally broad temperature spectrum, from cryogenic conditions at -200°C (-328°F) up to high-heat applications at +260°C (500°F).

This makes them suitable for a wide variety of equipment, including steam systems, industrial ovens, and heat exchangers, where the material must withstand significant thermal stress and cycling without becoming brittle or degrading.

Superior Mechanical Conformability

Unlike rigid gaskets, PTFE is soft and has a high compression ratio. This allows the material to "flow" and conform to the micro-imperfections present on flange surfaces.

This ability to embed into fine cracks and compensate for minor flange irregularities, displacement, or uneven bolt loading is what actively prevents leaks and ensures a tight seal.

Expanded PTFE (ePTFE): Enhanced Sealing for Critical Applications

Expanded PTFE (ePTFE) is a specialized form of PTFE engineered for even greater sealing performance by introducing a porous microstructure.

The Advantage of a Porous Structure

The manufacturing process creates a multidirectional fibrous structure within the PTFE. This gives ePTFE gaskets superior flexibility and compression resilience compared to standard solid PTFE.

They adapt more readily to irregular or damaged flange surfaces while requiring less bolt load to achieve a seal.

Maintaining Stable Sealing Force

A key benefit of ePTFE is its ability to maintain a stable bolt tightening force over time. It effectively compensates for flange deformation caused by temperature and pressure fluctuations.

This characteristic ensures a durable, low-maintenance seal that resists creep and maintains its integrity, which is paramount in environments where sealing failure is not an option.

Understanding the Trade-offs and Best Practices

While highly effective, the performance of a PTFE gasket is directly tied to its correct selection and installation. Its unique properties are not a substitute for sound engineering practices.

The Importance of Proper Flange Preparation

The conformability of PTFE helps compensate for minor imperfections, but it cannot overcome poorly prepared surfaces. For a reliable seal, flanges must be clean, dry, and as smooth as possible.

Any significant scratches, warping, or leftover debris on the flange face can compromise the integrity of the seal, regardless of the gasket material.

The Role of Correct Gasket Selection

"PTFE" is not a single material but a family of formulations. You must select the appropriate gasket based on the specific temperature, pressure, chemical media, and mechanical load requirements of your application.

Using the wrong type of PTFE can lead to premature failure. For example, a formulation designed for chemical resistance may not have the mechanical properties needed for a high-pressure system.

The Critical Nature of Controlled Tightening

Achieving an effective seal depends on applying a controlled and uniform bolt load. This ensures the gasket is compressed evenly across the entire flange face.

Uneven or excessive tightening can damage the gasket, crush its structure, and create leak paths. Always follow manufacturer specifications for torque values and tightening patterns.

Making the Right Choice for Your Goal

Selecting the right gasket comes down to identifying the most critical challenge in your specific application.

- If your primary focus is chemical purity or resistance: PTFE is the default choice for aggressive media and high-purity processes found in the chemical and pharmaceutical industries.

- If your primary focus is sealing imperfect or older equipment: Expanded PTFE (ePTFE) is ideal, as its superior conformability and resilience can create a reliable seal on less-than-perfect flange surfaces.

- If your primary focus is extreme temperature cycling: PTFE's unmatched stability from cryogenic lows to high-heat highs makes it a uniquely reliable performer where other materials would fail.

Ultimately, choosing PTFE is a decision to prioritize long-term reliability and integrity in your most demanding sealing applications.

Summary Table:

| Key Property | Benefit |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and caustics. |

| Temperature Stability | Performs from -200°C to +260°C (-328°F to 500°F). |

| Mechanical Conformability | Adapts to imperfect sealing surfaces to prevent leaks. |

| ePTFE Advantage | Enhanced flexibility and resilience for critical applications. |

Need a reliable sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, gaskets, liners, and custom labware. Our expertise ensures you get a component that delivers unparalleled chemical resistance, thermal stability, and sealing integrity for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key properties of PTFE that make it suitable for mechanical seals? Unlock Superior Sealing Performance

- How can PTFE be modified to enhance its sealing properties? Boost Durability & Performance

- What factors affect PTFE seal performance? Optimize Your System for Reliability & Longevity

- How do PTFE Liners contribute to patient safety? Ensuring Biocompatibility and Minimizing Trauma

- What industries benefit from the chemical resistance of PTFE lined butterfly valves? Key Applications & Selection Guide

- What are the applications of expanded PTFE? Unlock Versatility for Demanding Seals & Filters

- What are the typical properties of 15% glass-filled Teflon balls? Enhanced Durability for Demanding Applications

- What is an important characteristic of a high-quality PTFE liner? It's All About Compressive Strength