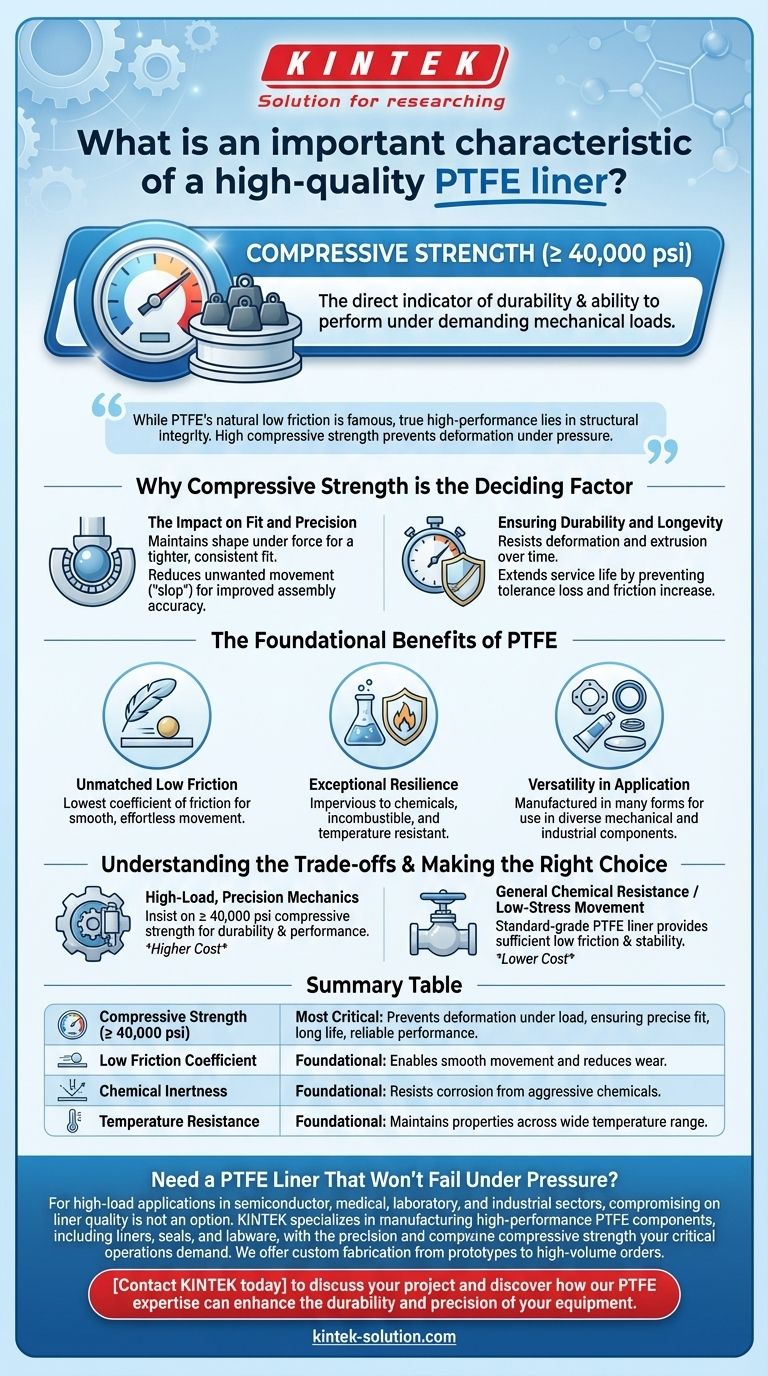

When evaluating a high-quality PTFE liner, the single most important characteristic to consider is its compressive strength. An exceptionally good liner should have a minimum compressive strength of 40,000 psi, as this figure is a direct indicator of its durability and ability to perform under demanding mechanical loads.

While PTFE's natural low friction is its most famous trait, the true measure of a high-performance liner is its structural integrity. High compressive strength is what translates PTFE's potential into reliable, long-term performance by preventing deformation under pressure.

Why Compressive Strength is the Deciding Factor

The quality of a PTFE liner is not inherent to the material alone; it is determined by how well it resists physical forces in its intended application. This is where compressive strength becomes the critical benchmark.

The Impact on Fit and Precision

A high compressive strength allows the liner to maintain its shape under significant force. This ensures a tighter, more consistent fit between mechanical components, such as the ball and race in a bearing.

This precision is crucial for reducing unwanted movement or "slop," which directly improves the overall performance and accuracy of the assembly.

Ensuring Durability and Longevity

Liners with lower compressive strength can deform or "extrude" under load over time. This leads to a loss of tolerance, increased friction, and ultimately, premature failure of the component.

A liner with at least 40,000 psi of compressive strength resists this degradation. It provides a stable, durable surface that significantly extends the service life of the entire assembly.

The Foundational Benefits of PTFE

Compressive strength distinguishes a high-quality liner, but the choice of PTFE as the base material is due to its unique combination of inherent properties.

Unmatched Low Friction

PTFE, commonly known by the brand name Teflon, has the lowest coefficient of friction of any known solid material. This makes it an ideal choice for applications where smooth, effortless movement is required.

Exceptional Resilience

The material is virtually impervious to chemical attack and is incombustible. It maintains its properties across a wide range of temperatures, making it suitable for use in harsh industrial environments.

Versatility in Application

PTFE can be manufactured in many forms and shapes. This versatility allows it to be used as a liner in a vast array of mechanical and industrial components.

Understanding the Trade-offs

While aiming for the highest quality is always a good goal, it's essential to match the material specification to the application's true needs.

Cost vs. Performance

Achieving a high compressive strength of 40,000 psi often involves specialized manufacturing processes or formulations. Consequently, these high-performance liners typically carry a higher cost than standard-grade alternatives.

The Importance of Application Matching

For a high-load, precision joint, investing in a high-strength liner is non-negotiable. However, for a low-load or less critical application, a standard PTFE liner may provide sufficient performance at a lower cost. Over-specifying can lead to unnecessary expense.

Making the Right Choice for Your Goal

Selecting the correct liner requires balancing performance requirements with practical considerations.

- If your primary focus is high-load, precision mechanics: Insist on a PTFE liner with a certified minimum compressive strength of 40,000 psi to guarantee durability and performance.

- If your primary focus is general chemical resistance or low-stress movement: A standard-grade PTFE liner will likely provide all the necessary benefits of low friction and material stability.

Ultimately, understanding that compressive strength is the key to durability empowers you to select a liner that will perform reliably for its intended lifespan.

Summary Table:

| Characteristic | Importance for a High-Quality PTFE Liner |

|---|---|

| Compressive Strength (≥ 40,000 psi) | Most Critical: Prevents deformation under load, ensuring a precise fit, long service life, and reliable performance. |

| Low Friction Coefficient | Foundational: Enables smooth movement and reduces wear. |

| Chemical Inertness | Foundational: Resists corrosion from aggressive chemicals. |

| Temperature Resistance | Foundational: Maintains properties across a wide temperature range. |

Need a PTFE Liner That Won't Fail Under Pressure?

For high-load applications in the semiconductor, medical, laboratory, and industrial sectors, compromising on liner quality is not an option. KINTEK specializes in manufacturing high-performance PTFE components, including liners, seals, and labware, with the precision and compressive strength your critical operations demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a solution tailored to your exact specifications and performance requirements.

Contact KINTEK today to discuss your project and discover how our PTFE expertise can enhance the durability and precision of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability