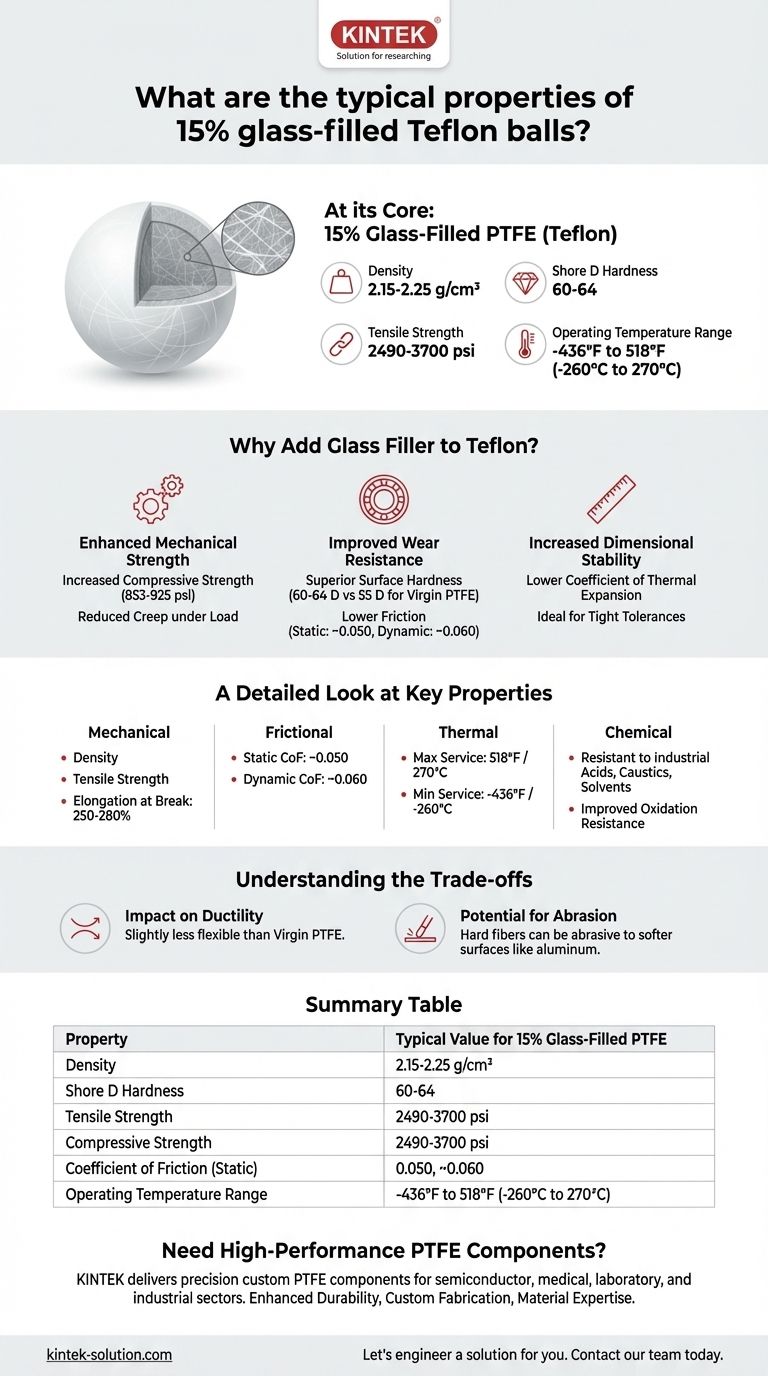

At its core, 15% glass-filled Teflon (PTFE) is a composite material designed to enhance the mechanical properties of virgin Teflon. These balls typically have a density of 2.15-2.25 g/cm³, a Shore D hardness of 60-64, a tensile strength between 2490-3700 psi, and an exceptionally low coefficient of friction. They retain Teflon's signature chemical inertness and wide operating temperature range, from -436°F to 518°F (-260°C to 270°C).

The fundamental reason to choose 15% glass-filled Teflon is to gain significant improvements in compressive strength, wear resistance, and dimensional stability over standard Teflon, making it suitable for demanding mechanical applications where virgin PTFE would fail.

Why Add Glass Filler to Teflon?

Virgin Teflon is renowned for its chemical inertness and low friction but is mechanically soft. Adding glass fibers is a common engineering solution to overcome these mechanical limitations without sacrificing Teflon's primary benefits.

Enhanced Mechanical Strength

Glass fibers act as a reinforcement within the PTFE matrix. This dramatically increases the material's compressive strength (853-925 psi) and reduces its tendency to deform or "creep" under a sustained load.

Improved Wear Resistance

The addition of glass significantly increases the surface hardness to a Shore D of 60-64, compared to around 55D for virgin PTFE. This enhancement, combined with a lower coefficient of friction, results in superior wear and abrasion resistance over the material's service life.

Increased Dimensional Stability

A common issue with plastics is thermal expansion and contraction. Glass-filled PTFE has a lower coefficient of thermal expansion, meaning its size remains more stable across its wide operating temperature range. This is critical for parts that require tight tolerances.

A Detailed Look at Key Properties

Understanding the specific values helps in qualifying this material for a precise engineering application.

Mechanical Specifications

The material's density is 2.15-2.25 g/cm³. Its tensile strength, or the force required to pull it apart, ranges from 2490 to 3700 psi. The elongation at break, a measure of ductility, is high at 250-280%.

Frictional Characteristics

Glass-filled Teflon has an exceptionally low coefficient of friction. The static coefficient (resistance to initial movement) is approximately 0.050, and the dynamic coefficient (resistance during motion) is 0.060.

Thermal Performance

This material operates effectively across an enormous temperature spectrum. Its maximum continuous service temperature is 518°F (270°C), and it remains functional down to -436°F (-260°C).

Chemical Resistance

Like virgin PTFE, the 15% glass-filled variant is resistant to virtually all known industrial acids, caustics, and solvents. The glass filler can also offer slightly improved resistance to oxidation.

Understanding the Trade-offs

While glass filler provides significant benefits, it's important to understand the associated compromises.

Impact on Ductility

While strength and hardness are increased, the material is slightly less flexible than virgin PTFE. The glass fibers reduce the polymer's natural ductility, though it remains a very tough material.

Potential for Abrasion

The hard glass fibers within the PTFE can be abrasive to softer mating surfaces, such as aluminum or other plastics. This must be considered when designing systems where the ball will be in dynamic contact with other components.

Comparison to Other Fill Grades

Higher concentrations of glass filler, such as 25%, will further increase hardness and compressive strength. However, this often comes at the expense of other properties, such as a higher coefficient of friction and reduced ductility. The 15% fill is often considered an excellent balance of properties.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the demands of your specific environment.

- If your primary focus is wear resistance and stability under load: 15% glass-filled Teflon is the superior choice over virgin PTFE for bearings, seals, and rollers.

- If your primary focus is extreme chemical inertness in a low-stress environment: Virgin Teflon may be sufficient and more cost-effective if enhanced mechanical strength is not a requirement.

- If your primary focus is a balance of mechanical performance and chemical resistance: The 15% glass-filled variant provides a significant upgrade in durability without compromising Teflon's core benefits.

Ultimately, selecting 15% glass-filled Teflon is a strategic engineering decision to enhance mechanical durability where virgin PTFE falls short.

Summary Table:

| Property | Typical Value for 15% Glass-Filled PTFE |

|---|---|

| Density | 2.15 - 2.25 g/cm³ |

| Shore D Hardness | 60 - 64 |

| Tensile Strength | 2490 - 3700 psi |

| Compressive Strength | 853 - 925 psi |

| Coefficient of Friction (Static) | ~0.050 |

| Operating Temperature Range | -436°F to 518°F (-260°C to 270°C) |

Need High-Performance PTFE Components?

When your application demands the superior mechanical properties of glass-filled Teflon, KINTEK delivers precision. We manufacture custom PTFE components—including seals, liners, labware, and balls—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Enhanced Durability: Components with improved wear resistance and dimensional stability.

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: The right PTFE composite for your specific mechanical and chemical environment.

Let's engineer a solution for you. Contact our team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance