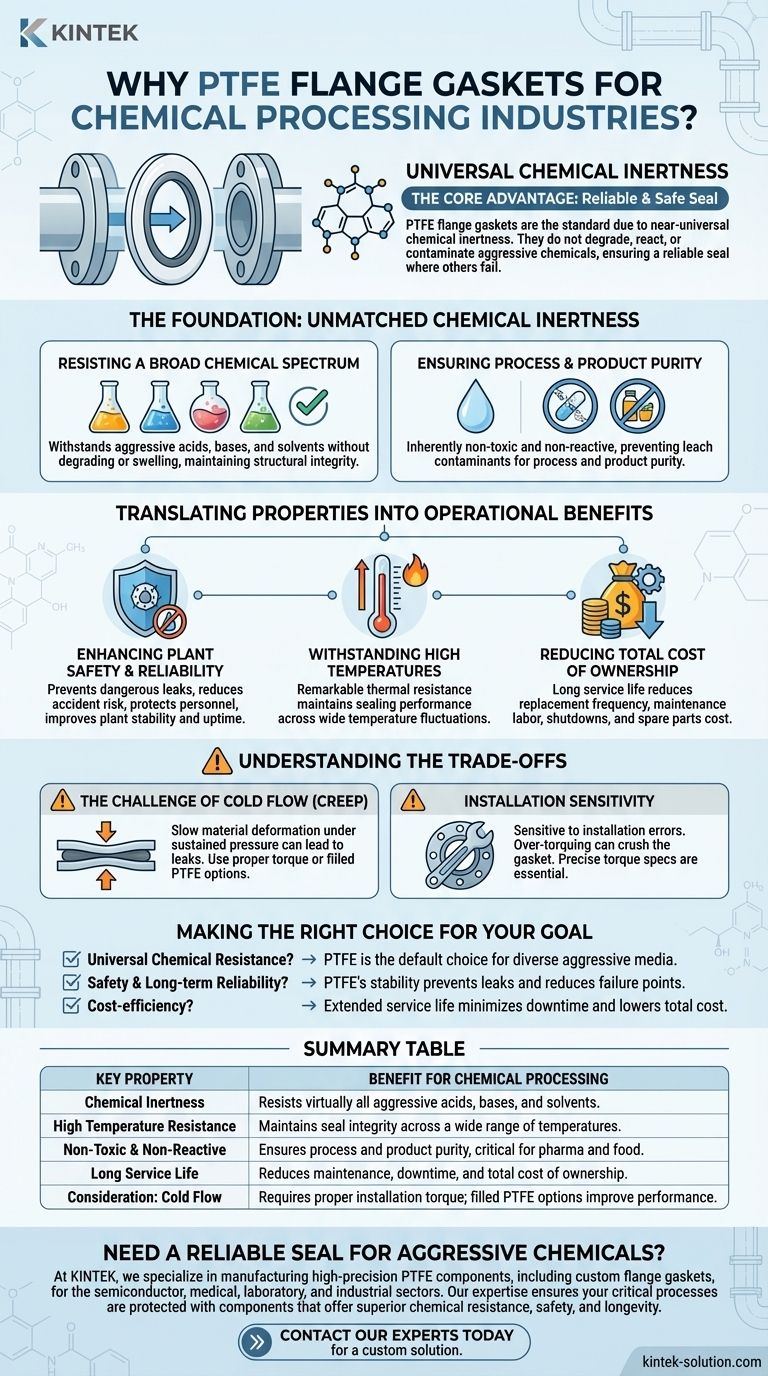

At its core, PTFE flange gaskets are the standard for the chemical processing industry due to their near-universal chemical inertness. This unique property ensures they will not degrade, react with, or contaminate the vast majority of aggressive chemicals, providing a reliable and safe seal where other materials would quickly fail.

The choice of PTFE is not merely about surviving chemical exposure. It is a strategic decision to enhance plant safety, increase operational uptime, and lower the total cost of ownership by preventing leaks and minimizing maintenance.

The Foundation: Unmatched Chemical Inertness

The primary reason for PTFE's dominance in chemical applications is its molecular stability. This translates into tangible benefits for any process involving corrosive or reactive substances.

Resisting a Broad Chemical Spectrum

Polytetrafluoroethylene (PTFE) is a fluoropolymer with exceptionally strong carbon-fluorine bonds, making it non-reactive with most chemicals. It can withstand prolonged exposure to aggressive acids, bases, and solvents without degrading or swelling.

This ensures the gasket maintains its structural integrity and sealing capability, preventing catastrophic failures in critical process lines.

Ensuring Process and Product Purity

Beyond just resisting attack, PTFE is inherently non-toxic and non-reactive. This means the gasket material itself will not leach contaminants into the process media.

This property is crucial not only for chemical processing but also for adjacent industries like pharmaceuticals and food processing, where product purity is a non-negotiable requirement.

Translating Properties into Operational Benefits

A gasket's material properties are only valuable if they improve the plant's performance. PTFE's characteristics directly contribute to a safer and more efficient operation.

Enhancing Plant Safety and Reliability

The most significant operational benefit is enhanced safety. By providing a dependable seal that resists chemical attack and pressure variations, PTFE gaskets prevent dangerous leaks of hazardous materials.

This reliability reduces the risk of unforeseen accidents, protects personnel, and improves the overall stability and uptime of the plant.

Withstanding High Temperatures

PTFE is renowned for its remarkable thermal resistance. It maintains its sealing performance across a wide temperature range common in chemical processes.

This stability under thermal stress is critical for preventing seal failure during temperature fluctuations, a common occurrence in many industrial applications.

Reducing Total Cost of Ownership

While the initial cost is a factor, the true value of PTFE gaskets lies in their long service life. Their resistance to corrosion and high temperatures means they require less frequent replacement.

This durability leads to significant long-term savings by minimizing maintenance labor, reducing shutdown periods, and lowering the overall cost of spare parts inventory.

Understanding the Trade-offs

No material is perfect. A true technical understanding requires acknowledging PTFE's limitations to ensure proper application and prevent failures.

The Challenge of Cold Flow (Creep)

Standard PTFE is a relatively soft material and can be prone to "cold flow," or creep. This is a slow deformation of the material under sustained pressure, which can eventually lead to a loss of sealing force and potential leaks.

This is why proper flange torque and design are critical. In high-pressure or high-temperature applications, filled PTFE (which includes materials like glass or carbon) is often used to improve creep resistance.

Installation Sensitivity

Due to its softness, PTFE gaskets are more sensitive to installation errors than harder gasket materials. Over-torquing is a common mistake that can crush the gasket, causing it to extrude out of the flange and fail prematurely.

Following precise torque specifications is not just a recommendation; it is essential for achieving a reliable, long-lasting seal.

Making the Right Choice for Your Goal

Selecting the right gasket is about matching the material's strengths to your operational priorities.

- If your primary focus is universal chemical resistance: PTFE is the default choice for sealing flanges that handle a wide variety of aggressive media.

- If your primary focus is safety and long-term reliability: PTFE's chemical and thermal stability directly prevents leaks and reduces potential failure points over the equipment's lifecycle.

- If your primary focus is cost-efficiency: The extended service life of PTFE gaskets minimizes maintenance downtime and replacement costs, lowering the total cost of ownership.

By understanding both its unmatched strengths and its specific limitations, you can leverage PTFE to achieve superior operational excellence.

Summary Table:

| Key Property | Benefit for Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. |

| High Temperature Resistance | Maintains seal integrity across a wide range of process temperatures. |

| Non-Toxic & Non-Reactive | Ensures process and product purity, critical for pharma and food. |

| Long Service Life | Reduces maintenance, downtime, and total cost of ownership. |

| Consideration: Cold Flow | Requires proper installation torque; filled PTFE options improve performance. |

Need a reliable seal for aggressive chemicals?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom flange gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your critical processes are protected with components that offer superior chemical resistance, safety, and longevity.

Let us help you enhance your plant's reliability and efficiency. Contact our experts today to discuss your specific application and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does the contact pattern of PTFE seals compare to elastomer seals? The Key to Low-Friction Performance

- What are the advantages of PTFE lined diaphragm valves? Superior Corrosion & Purity Control

- What are the main advantages of using PTFE over rubber in rotary shaft seals? Superior Performance in Extreme Conditions

- What is the purpose of PTFE guide strips? Achieve Smooth, Reliable Motion in Your Systems

- What are the main applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & High-Temp Environments

- In which industries are PTFE rotary shaft lip seals commonly used? Essential for Extreme Conditions

- Why are extruded PTFE rods suitable for high-temperature applications? Superior Heat Resistance for Demanding Industries

- How are PTFE seals used in medical device and life sciences applications? Essential for Sterility & Precision