While PTFE expansion bellows have a higher initial purchase price, their reputation as a cost-effective long-term investment is built on a foundation of superior durability, drastically lower maintenance needs, and enhanced operational reliability. This combination significantly reduces the total cost of ownership compared to less resilient rubber or metal alternatives.

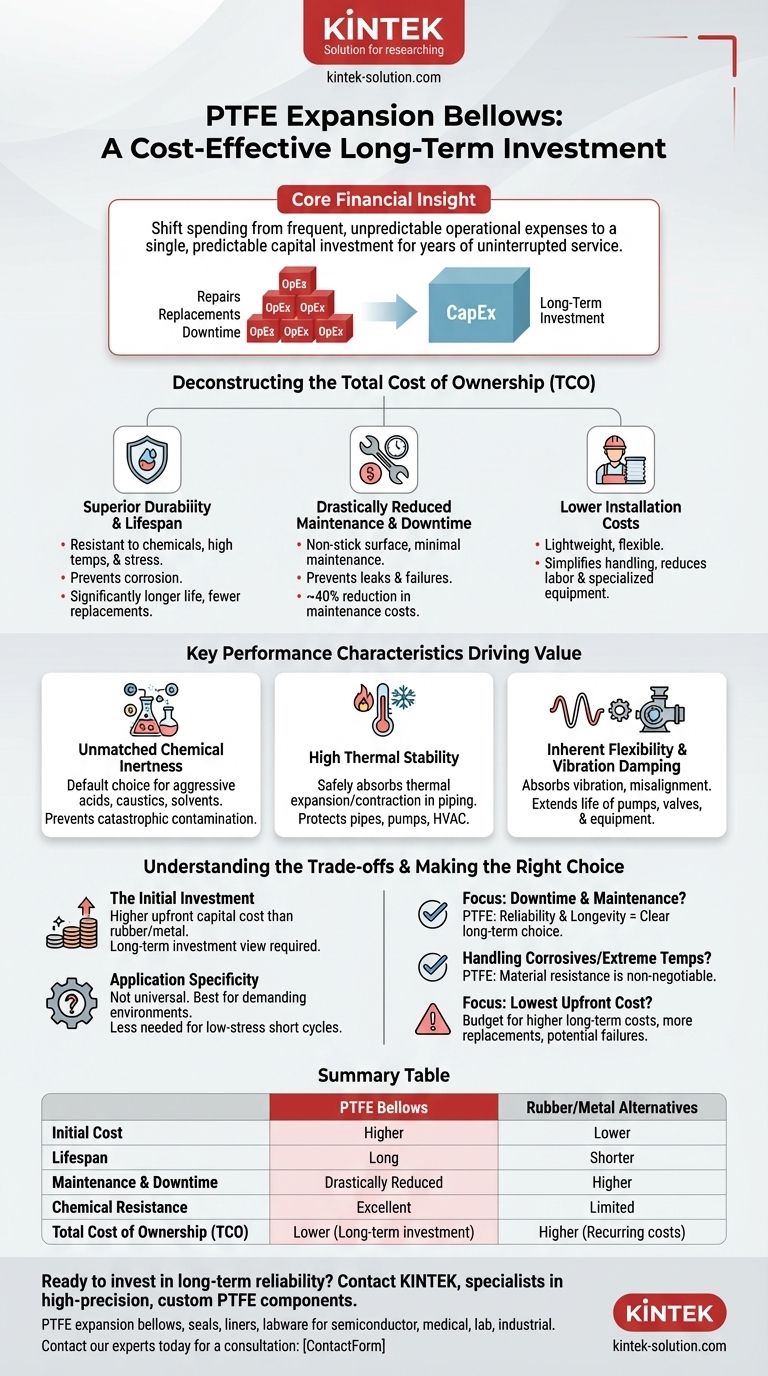

The core financial insight is simple: PTFE bellows shift your spending from frequent, unpredictable operational expenses (repairs, replacements, downtime) to a single, predictable capital investment that pays dividends through years of uninterrupted service.

Deconstructing the Total Cost of Ownership

To understand the value of PTFE, you must look beyond the initial invoice. The true cost of an industrial component is measured over its entire lifecycle, including installation, maintenance, and the cost of failure.

Superior Durability and Lifespan

PTFE is exceptionally resistant to nearly all industrial chemicals, high temperatures, and physical stress. This chemical inertness prevents the corrosion and degradation that cause rubber and metal bellows to fail prematurely.

This inherent toughness means PTFE bellows last significantly longer, minimizing the frequency and cost of replacement cycles.

Drastically Reduced Maintenance and Downtime

The non-adhesive, "non-stick" surface of PTFE prevents material buildup, which simplifies cleaning and inspection. More importantly, their resilience means they require minimal preventative maintenance.

For any industrial operation, unplanned downtime is the most significant hidden cost. By preventing leaks and failures, PTFE bellows enhance system reliability, directly reducing costly production stoppages. One chemical plant, for instance, reported a 40% reduction in maintenance costs after making the switch.

Lower Installation Costs

Compared to metal expansion joints, which are often heavy and rigid, PTFE bellows are lightweight and flexible. This simplifies handling and positioning during installation.

This ease of installation translates directly to lower costs by reducing the labor hours and eliminating the need for specialized heavy-lifting equipment.

Key Performance Characteristics Driving Value

The financial benefits of PTFE are a direct result of its unique material properties. These characteristics ensure the component not only lasts longer but also protects the entire system it's a part of.

Unmatched Chemical Inertness

PTFE's ability to withstand aggressive acids, caustics, and solvents makes it the default choice for chemical processing, pharmaceutical, and food-grade applications where contamination or corrosion would lead to catastrophic failure.

High Thermal Stability

Piping systems expand and contract with temperature changes. PTFE bellows safely absorb this thermal movement, preventing stress and potential damage to pipes, pumps, and vessels, which is critical in systems like HVAC.

Inherent Flexibility and Vibration Damping

PTFE bellows effectively absorb system vibration and pipeline misalignment. This protects connected equipment from damaging mechanical stress, extending the life of more expensive components like pumps and valves.

Understanding the Trade-offs

An objective analysis requires acknowledging the primary consideration that gives decision-makers pause.

The Initial Investment

There is no question that the upfront capital cost of PTFE bellows is higher than that of many rubber or metal options. It is not the cheapest component you can buy at the outset.

This requires a shift in perspective from viewing the bellows as a disposable part to seeing it as a long-term investment in system stability and safety.

Application Specificity

While incredibly versatile, PTFE is not a universal solution for every possible scenario. In low-stress, non-corrosive systems with a short expected lifecycle, a less expensive alternative might be sufficient. The superior properties of PTFE are most valuable in demanding environments.

Making the Right Choice for Your System

Your decision should be guided by your operational priorities and the demands of your specific application.

- If your primary focus is minimizing operational downtime and maintenance: The reliability and longevity of PTFE make it the clear long-term choice.

- If you are handling corrosive chemicals or extreme temperatures: The material resistance of PTFE is a non-negotiable requirement for system safety and integrity.

- If your primary focus is the lowest possible upfront capital expense: Be prepared to budget for higher long-term costs related to maintenance, more frequent replacements, and the potential for costly system failures.

Ultimately, choosing PTFE expansion bellows is an investment in your system's long-term stability, safety, and financial efficiency.

Summary Table:

| Factor | PTFE Bellows | Rubber/Metal Alternatives |

|---|---|---|

| Initial Cost | Higher | Lower |

| Lifespan | Long (Superior durability) | Shorter (Prone to degradation) |

| Maintenance & Downtime | Drastically Reduced | Higher (Frequent repairs/replacements) |

| Chemical Resistance | Excellent (Inert to most chemicals) | Limited (Varies by material) |

| Total Cost of Ownership | Lower (Long-term investment) | Higher (Due to recurring costs) |

Ready to invest in long-term system reliability and reduce your total cost of ownership?

At KINTEK, we specialize in manufacturing high-precision, custom PTFE components—including expansion bellows, seals, liners, and labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that delivers superior performance and durability, protecting your entire system from costly downtime and failures.

Let us help you make a cost-effective investment in your operation's future. Contact our experts today for a consultation on your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary functions of PTFE lined butterfly valves? Achieve Reliable Flow Control in Hostile Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the steps involved in PTFE isostatic pressing? A Guide to Uniform, Complex Parts

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the disadvantages of PTFE ball valves? Key Limitations in Chemical & Industrial Applications

- What are some best practices for using a Teflon sheet? Ensure Flawless Heat Press Results Every Time

- What are some key applications of low-friction PTFE in bearings and bushings? Achieve Maintenance-Free Performance

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments