While prized for its exceptional chemical resistance, the primary disadvantages of PTFE in ball valves stem from its physical and mechanical properties. The material is inherently soft, making it susceptible to deformation under pressure (cold flow), and its high rate of thermal expansion limits its effective temperature and pressure range. It is also poorly suited for abrasive media or sustained throttling applications, where the soft seat material can be easily damaged.

The core issue with PTFE is a trade-off: its incredible chemical inertness and low friction come from its nature as a soft polymer. This softness is also the source of its biggest weaknesses—sensitivity to mechanical stress, pressure, and temperature changes—which must be carefully managed in any valve design.

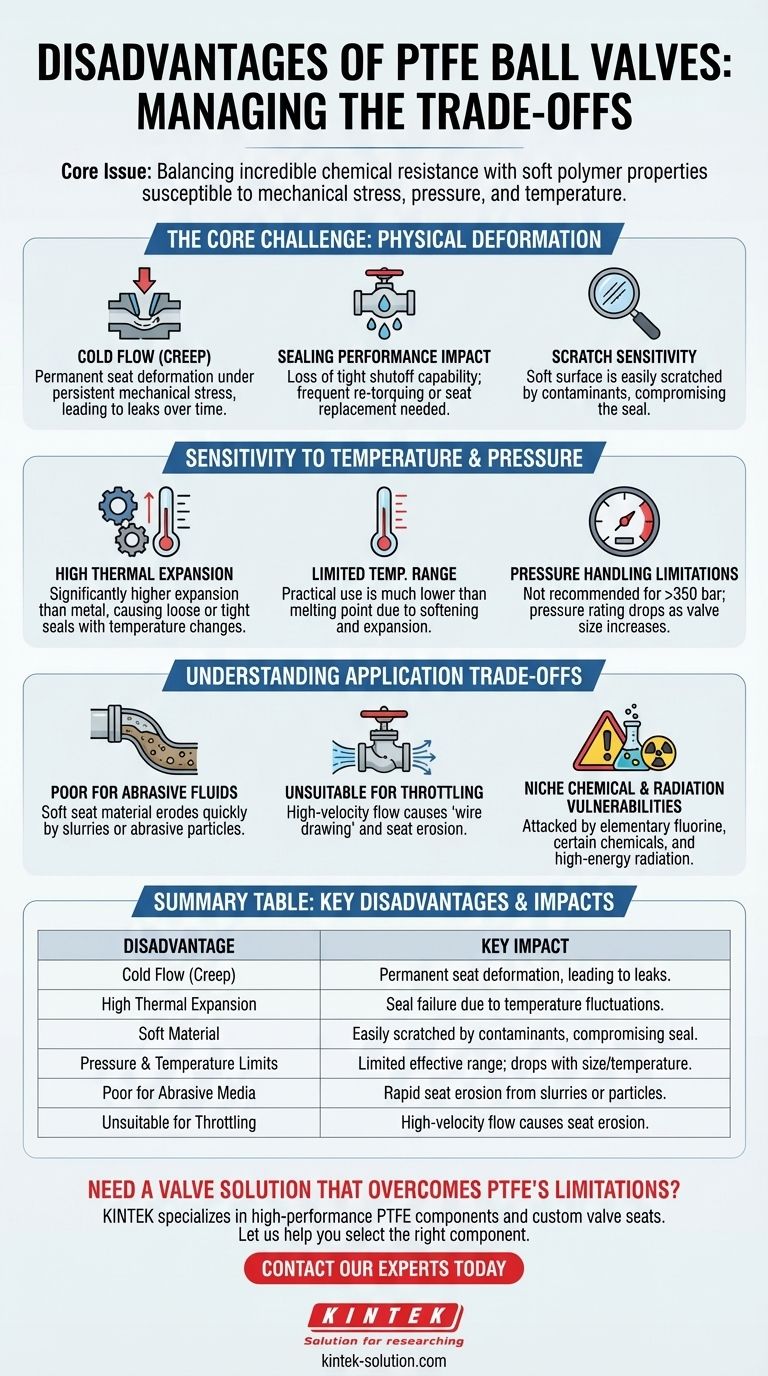

The Core Challenge: Physical Deformation

The most significant limitations of PTFE are not chemical, but mechanical. Its soft, plastic nature creates specific engineering challenges that define its appropriate use.

Understanding "Cold Flow"

Cold flow, or creep, is the tendency of a solid material to deform permanently under persistent mechanical stress. PTFE is particularly susceptible to this phenomenon.

Even at room temperature, the constant pressure from the ball against the valve seat can slowly cause the PTFE to change shape. This can eventually compromise the integrity of the seal.

The Impact on Sealing Performance

This deformation means that over time, a PTFE-seated valve can lose its tight shutoff capability, leading to leaks.

The valve may require re-torquing or seat replacement more frequently than valves with harder seat materials, especially in high-pressure applications.

Why Scratches Are a Critical Failure Point

Because PTFE is soft, its surface can be easily scratched or scored by contaminants in the process fluid.

Even a minor scratch on the sealing surface can create a path for leakage, immediately compromising the valve's performance.

Sensitivity to Temperature and Pressure

PTFE's physical properties change significantly with temperature, which directly impacts its performance envelope as a valve seat material.

The Problem of Thermal Expansion

PTFE has a much higher coefficient of thermal expansion than the metal body of the valve.

This means that as temperatures fluctuate, the PTFE seat will expand or contract far more than the surrounding steel. This can cause the seal to become too loose (causing leaks) or too tight (increasing actuation torque).

Limited Effective Temperature Range

This high thermal expansion is the primary reason PTFE has a limited useful temperature range. While its melting point is high (326°C), its practical use is well below that.

As temperatures rise, the material softens and expands, drastically reducing its ability to withstand pressure without deforming.

Pressure Handling Limitations

PTFE seats are generally not recommended for pressures exceeding 350 bar (around 5,000 psi).

This pressure rating drops significantly as the valve size increases. For a 2-inch valve (DN50), the limit may be closer to 150 bar, as the larger surface area of the seat is more prone to cold flow.

Understanding Application Trade-offs

The physical weaknesses of PTFE make it unsuitable for certain common industrial applications where other valve types excel.

Not Suitable for Abrasive Fluids

PTFE is a poor choice for services containing slurries or other abrasive particles.

The soft seat material will be quickly eroded by the particles, leading to rapid failure of the seal and leakage.

Poor Performance in Throttling

Using a PTFE-seated ball valve for sustained throttling (regulating flow in a partially open position) is not recommended.

The high-velocity flow across the partially exposed seat can cause erosion and damage, a phenomenon known as "wire drawing," which will destroy the seat's ability to provide a bubble-tight seal.

Niche Chemical and Radiation Vulnerabilities

While chemically resistant to most substances, PTFE can be attacked by highly reactive agents like elementary fluorine and certain other chemicals at high temperatures and pressures.

It also has poor resistance to high-energy radiation, which can cause its molecular structure to break down.

Making the Right Choice for Your Application

To select the right valve seat, you must align the material's properties with your system's specific operational demands. Using fillers like glass or carbon can mitigate some of PTFE's weaknesses, but understanding the base material is crucial.

- If your primary focus is broad chemical compatibility in a stable, low-pressure system: Standard PTFE is an excellent and cost-effective choice.

- If your system involves significant temperature cycling or sustained high pressure: Consider a filled PTFE or a harder seat material like PEEK or metal.

- If your application requires throttling or handles abrasive media: A PTFE-seated ball valve is the wrong tool; look for metal-seated or other severe-service valve designs.

Ultimately, understanding these material limitations is the key to designing a reliable and long-lasting fluid control system.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Cold Flow (Creep) | Permanent seat deformation under pressure, leading to leaks. |

| High Thermal Expansion | Seal failure due to temperature fluctuations. |

| Soft Material | Easily scratched by contaminants, compromising the seal. |

| Pressure & Temperature Limits | Limited effective range; pressure rating drops with size/temperature. |

| Poor for Abrasive Media | Rapid seat erosion from slurries or particles. |

| Unsuitable for Throttling | High-velocity flow causes seat erosion (wire drawing). |

Need a valve solution that overcomes PTFE's limitations?

PTFE's weaknesses—like cold flow and sensitivity to abrasives—can be critical failure points in demanding applications. KINTEK specializes in manufacturing high-performance PTFE components, including custom valve seats, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your fluid control system is reliable and long-lasting.

Let us help you select or engineer the right component for your specific pressure, temperature, and chemical requirements.

Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide