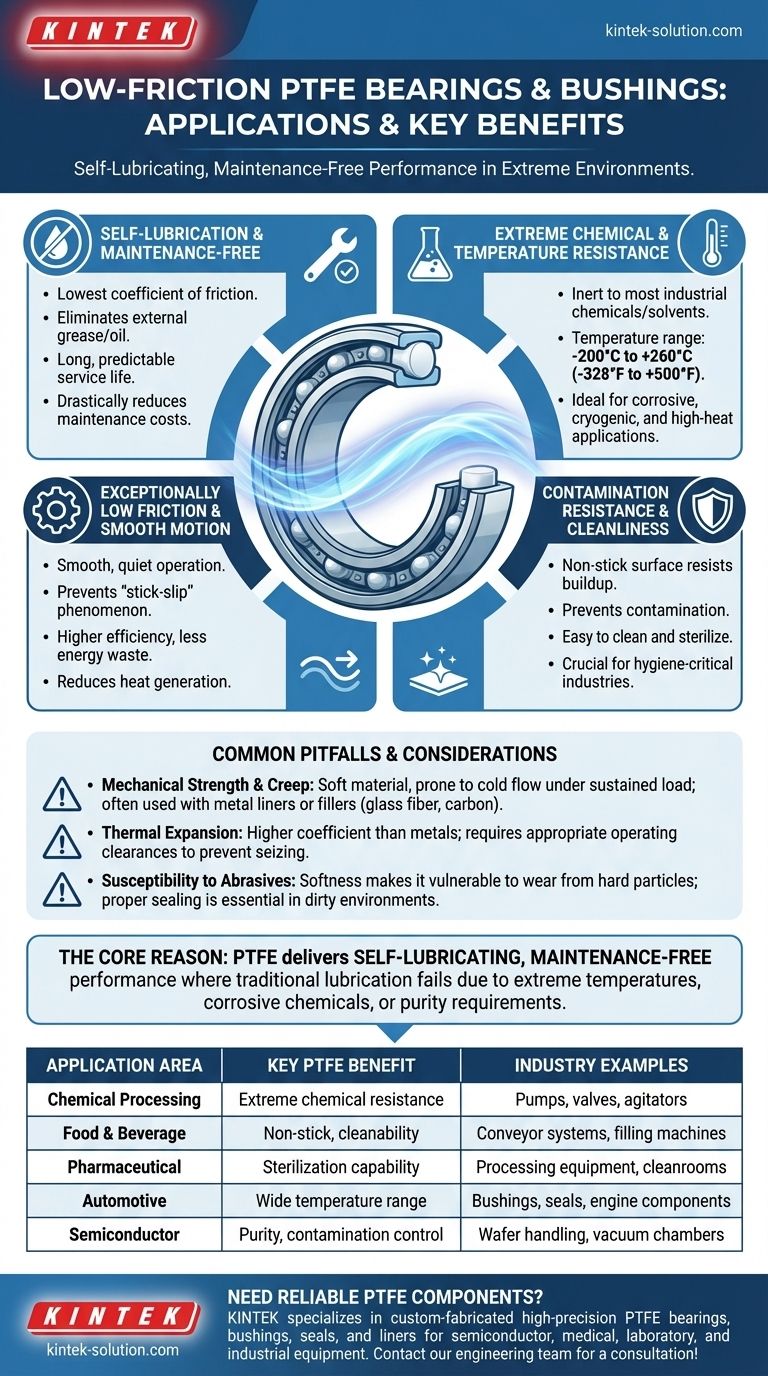

In practice, Polytetrafluoroethylene (PTFE) is a material of choice for bearings and bushings in applications where traditional lubrication is impossible or undesirable. Its key applications include machinery for chemical processing, food and beverage production, and automotive components, as well as uses in pharmaceutical manufacturing and as electrical insulation.

The core reason for using PTFE is not just its low friction, but its unique ability to deliver self-lubricating, maintenance-free performance in environments—defined by extreme temperatures, corrosive chemicals, or purity requirements—where conventional metal bearings would quickly fail.

The Core Properties Driving PTFE Adoption

To understand where to apply PTFE, we must first understand the fundamental properties that set it apart from other bearing materials. These characteristics work in concert to solve specific engineering challenges.

Self-Lubrication and Maintenance-Free Operation

PTFE has one of the lowest coefficients of friction of any solid material, which allows it to function as a self-lubricating surface.

This eliminates the need for external grease or oil, drastically reducing maintenance costs and complexity. The result is a clean, dry-running component with a long and predictable service life.

Extreme Chemical and Temperature Resistance

This material is nearly completely inert, resisting almost all industrial chemicals and solvents. This makes it ideal for equipment that handles corrosive substances.

Furthermore, PTFE maintains its integrity across an exceptionally wide temperature range, from -200°C to +260°C (-328°F to +500°F), enabling its use in cryogenic and high-heat applications.

Exceptionally Low Friction and Smooth Motion

The low-friction surface provides smooth, quiet operation and prevents the "stick-slip" phenomenon, where motion starts and stops abruptly at low speeds.

This consistent performance allows for higher efficiency, as less energy is wasted overcoming friction. This, in turn, reduces heat generation, especially under high loads or at high sliding velocities.

Contamination Resistance and Cleanliness

PTFE features a non-stick surface that resists the buildup of process materials. This is a critical advantage in industries where hygiene is paramount.

This property prevents contamination and makes equipment significantly easier to clean and sterilize, a non-negotiable requirement in food, beverage, and pharmaceutical manufacturing.

Common Pitfalls and Considerations

While PTFE offers significant advantages, it is not a universal solution. Understanding its limitations is critical for successful implementation and avoiding premature failure.

Mechanical Strength and Creep

Pure PTFE is a relatively soft material and can be prone to "cold flow" or creep, where it deforms permanently under a sustained load.

For high-load applications, PTFE is often used as a liner within a more rigid metal housing or blended with fillers like glass fiber, carbon, or bronze to improve its mechanical strength and wear resistance.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This means it expands and contracts more significantly with temperature changes.

Designers must account for this by engineering appropriate operating clearances to prevent the bearing from seizing or becoming too loose within its housing.

Susceptibility to Abrasives

While excellent in clean environments, PTFE's relative softness makes it susceptible to wear from hard, abrasive particles.

In environments with significant contamination (like dirt or grit), proper sealing is essential to protect the bearing surface and ensure a long service life.

Making the Right Choice for Your Application

Selecting the correct bearing material depends entirely on the primary challenge you need to solve.

- If your primary focus is purity or chemical compatibility: PTFE is the definitive choice for food-grade, pharmaceutical, or corrosive chemical applications where lubricant contamination is unacceptable.

- If your primary focus is eliminating maintenance: Use PTFE in inaccessible locations or in machinery where downtime for lubrication is costly and disruptive.

- If your primary focus is smooth motion under load: PTFE bearings excel at providing consistent, stick-slip-free movement at both high and low speeds.

- If your primary focus is extreme temperature resilience: PTFE is one of the few materials that can provide reliable bearing performance in both cryogenic and high-temperature environments.

Ultimately, choosing PTFE is a decision to prioritize clean, consistent, and maintenance-free performance in challenging operational conditions.

Summary Table:

| Application Area | Key PTFE Benefit | Industry Examples |

|---|---|---|

| Chemical Processing | Extreme chemical resistance | Pumps, valves, agitators |

| Food & Beverage | Non-stick, cleanability | Conveyor systems, filling machines |

| Pharmaceutical | Sterilization capability | Processing equipment, cleanrooms |

| Automotive | Wide temperature range | Bushings, seals, engine components |

| Semiconductor | Purity, contamination control | Wafer handling, vacuum chambers |

Need reliable PTFE components for your demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom bearings, bushings, seals, and liners—for semiconductor, medical, laboratory, and industrial equipment. Our expertise ensures you get maintenance-free, chemically resistant solutions that withstand extreme temperatures and purity requirements.

Let us help you solve your most challenging bearing problems with custom-fabricated PTFE components, from prototypes to high-volume production. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments