Fundamentally, the primary functions of a PTFE lined butterfly valve are to provide reliable shutoff and precise flow control. As a shutoff valve, it completely isolates a section of pipe, creating a leak-proof seal to prevent both internal system leakage and external fugitive emissions. As a flow control valve, its rotating disc allows for the modulation of fluid passing through the system.

The core purpose of a PTFE lined butterfly valve is not just to control flow, but to do so reliably within highly corrosive, high-temperature, or high-purity environments. The PTFE lining acts as a protective shield, isolating the valve's structural components from aggressive media that would rapidly degrade standard valves.

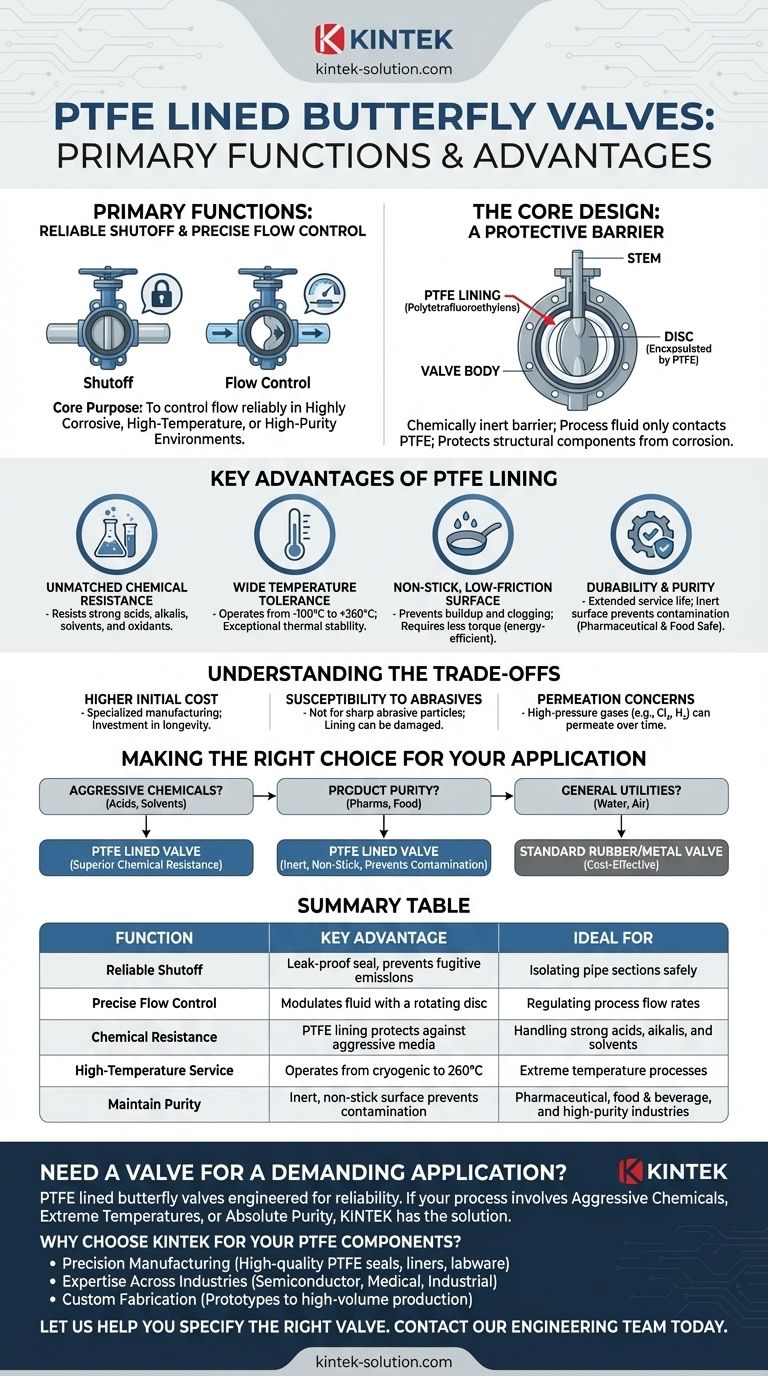

The Core Design: A Protective Barrier

The Basic Butterfly Valve Mechanism

A butterfly valve consists of a valve body, which is essentially a ring, and a disc mounted on a central stem. A ninety-degree rotation of this stem moves the disc from a position parallel to the flow (fully open) to a position perpendicular to the flow (fully closed).

The Critical Role of the PTFE Lining

The defining feature is the PTFE (polytetrafluoroethylene) that lines the entire wetted interior surface of the valve body and often encapsulates the disc. This lining creates a chemically inert barrier, ensuring that the process fluid only ever comes into contact with the PTFE, not the metal valve body or components.

This design effectively protects the valve's structural materials from corrosion and chemical attack.

Key Advantages of the PTFE Lining

Unmatched Chemical Resistance

PTFE is renowned for its resistance to a vast range of chemicals, including strong acids, alkalis, oxidants, and organic solvents. This makes it an ideal choice for the most aggressive chemical processing applications where other materials would fail.

Wide Temperature Tolerance

These valves demonstrate exceptional thermal stability. They can operate effectively in high-temperature services, typically up to 200-260°C, while also maintaining their properties at cryogenic temperatures as low as -100°C.

Non-Stick, Low-Friction Surface

The non-stick nature of PTFE is a significant operational advantage. It prevents media from building up on the valve's internal surfaces, which is crucial when handling slurries, viscous fluids, or media that could otherwise clog the mechanism.

This low coefficient of friction also means less torque is required to operate the valve, allowing for smaller, more energy-efficient actuators.

Durability and Purity

The PTFE lining prevents wear and tear on the core valve components, significantly extending the valve's service life and reducing maintenance requirements. Because it is inert, it also ensures that the process media is not contaminated by the valve materials, a critical factor in pharmaceutical and food production.

Understanding the Trade-offs and Limitations

Higher Initial Cost

The specialized manufacturing process and the cost of the PTFE material itself make these valves more expensive upfront than standard rubber-lined or unlined metal butterfly valves. This investment is justified by their longevity in harsh environments.

Susceptibility to Abrasives

While excellent for corrosive fluids, PTFE is a relatively soft material. It is not the ideal choice for services containing sharp, abrasive particles, which can physically damage the lining over time and compromise its integrity.

Permeation Concerns

In certain high-pressure gas applications, smaller molecules (like chlorine or hydrogen) can slowly permeate through the PTFE lining. This is a specific engineering consideration that must be evaluated for the intended service.

Making the Right Choice for Your Application

Selecting the correct valve requires understanding the specific demands of your process.

- If your primary focus is handling aggressive chemicals (acids, solvents): The superior chemical resistance of a PTFE lined valve makes it the safest and most reliable choice.

- If your primary focus is product purity (pharmaceuticals, food & beverage): The inert, non-stick surface prevents contamination and buildup, making it an ideal solution.

- If your primary focus is general utilities (water, air, non-corrosive fluids): A PTFE lined valve is likely overkill; a more cost-effective standard rubber-lined or metal valve would be sufficient.

Ultimately, selecting a PTFE lined butterfly valve is a strategic decision driven by the chemical and thermal hostility of your process environment, not just the basic need for flow control.

Summary Table:

| Function | Key Advantage | Ideal For |

|---|---|---|

| Reliable Shutoff | Leak-proof seal, prevents fugitive emissions | Isolating pipe sections safely |

| Precise Flow Control | Modulates fluid with a rotating disc | Regulating process flow rates |

| Chemical Resistance | PTFE lining protects against aggressive media | Handling strong acids, alkalis, and solvents |

| High-Temperature Service | Operates from cryogenic to 260°C | Extreme temperature processes |

| Maintain Purity | Inert, non-stick surface prevents contamination | Pharmaceutical, food & beverage, and high-purity industries |

Need a Valve for a Demanding Application?

PTFE lined butterfly valves are engineered for reliability where standard valves fail. If your process involves aggressive chemicals, extreme temperatures, or requires absolute product purity, KINTEK has the solution.

Why choose KINTEK for your PTFE components?

- Precision Manufacturing: We specialize in high-quality PTFE seals, liners, labware, and custom components.

- Expertise Across Industries: We serve the semiconductor, medical, laboratory, and industrial sectors, understanding your unique challenges.

- Custom Fabrication: From initial prototypes to high-volume production runs, we deliver components tailored to your exact specifications.

Let us help you specify the right valve for your system. Contact our engineering team today to discuss your application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability