Properly using a Teflon sheet is a simple practice that significantly improves the quality and consistency of heat press applications. The core best practices involve selecting the right size, keeping the sheet clean, storing it flat or rolled to prevent creases, and replacing it when it shows signs of wear like discoloration or tearing.

A Teflon sheet is more than a protective barrier; it is a critical tool for managing heat and protecting your investment. Understanding its properties and limitations is the key to preventing project defects and prolonging the life of both your designs and your equipment.

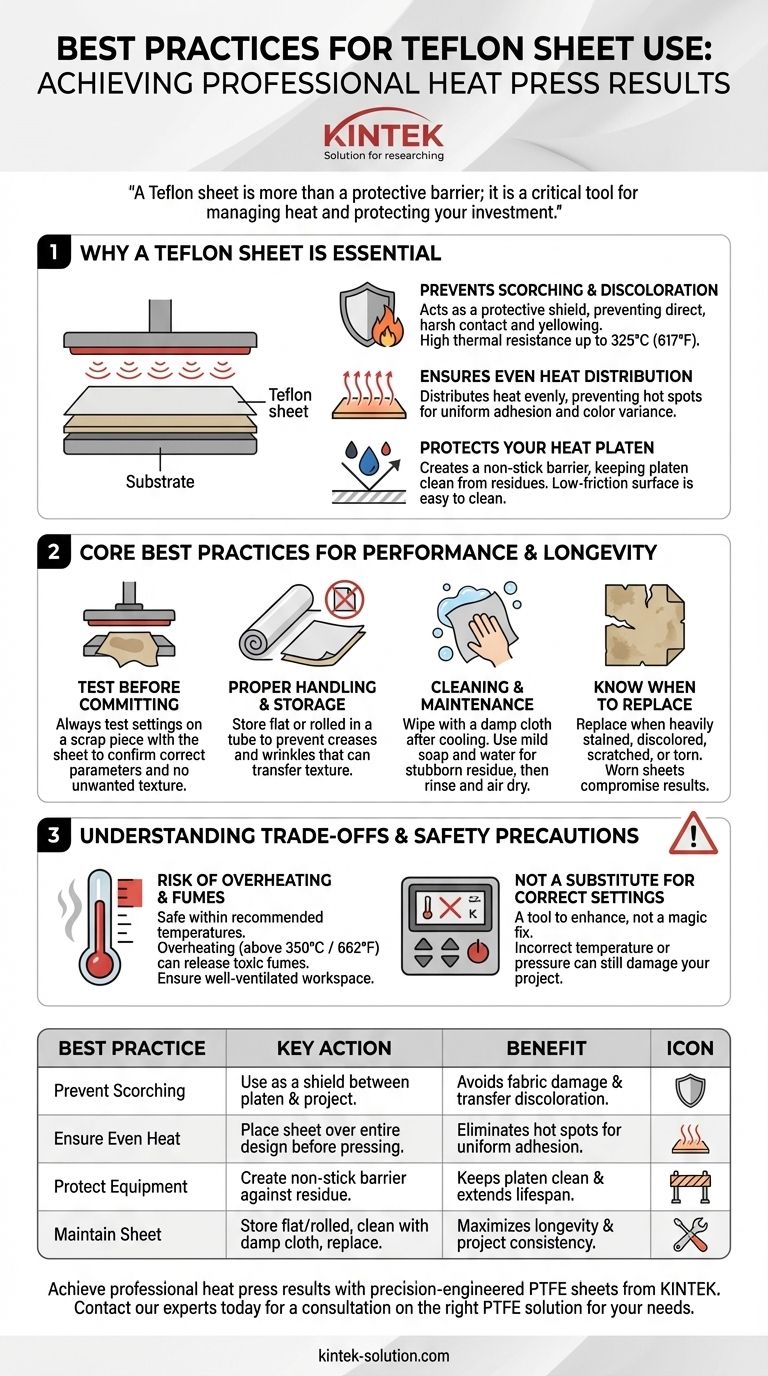

Why a Teflon Sheet is Essential in Heat Applications

Using a Teflon sheet (also known as a PTFE sheet) is not just a suggestion; it's a foundational step for achieving professional-grade results. Its unique properties are directly responsible for solving the most common heat-pressing problems.

It Prevents Scorching and Discoloration

The primary function of the sheet is to act as a protective shield between the hot platen and your project. This prevents direct, harsh contact that can scorch delicate fabrics or yellow the transfer paper.

Because of its high thermal resistance—handling temperatures up to 325°C (617°F)—it effectively moderates the heat transfer.

It Ensures Even Heat Distribution

The sheet helps to distribute the heat from the platen more evenly across the entire surface of your design.

This buffering effect is crucial for preventing hot spots, which can lead to uneven adhesion or color variance in your final transfer.

It Protects Your Heat Platen

The sheet creates a non-stick barrier that stops inks, adhesives, and other residues from transferring onto your heat platen.

A clean platen is essential for future projects, as any residue can easily stain or ruin the next item you press. Teflon's chemical inertness and low-friction surface make it exceptionally easy to clean.

Core Best Practices for Performance and Longevity

To get the most out of your Teflon sheet, integrate these practices into your workflow.

Test Before Committing

Before pressing a final garment or substrate, always test your settings (time, temperature, pressure) with the Teflon sheet on a scrap piece of the same material.

This allows you to confirm that your settings are correct and that the sheet is not imparting any unwanted texture or residue.

Proper Handling and Storage

Creases and wrinkles in your Teflon sheet can transfer an unwanted texture to your design.

To prevent this, store the sheet flat or gently rolled in a tube. Avoid folding it at all costs.

Cleaning and Maintenance

For routine cleaning, simply wipe the sheet with a damp cloth after it has cooled down.

If you have stubborn ink or adhesive residue, use a soft cloth with a small amount of mild soap and water. Rinse thoroughly and allow it to air dry completely before its next use.

Know When to Replace Your Sheet

A Teflon sheet is a consumable item. It needs to be replaced when it becomes heavily stained, discolored, scratched, or develops any tears or wrinkles that cannot be removed.

Using a worn-out sheet compromises your results and can damage your project. A discolored sheet, for example, may no longer distribute heat as evenly.

Understanding the Trade-offs and Safety Precautions

While highly effective, a Teflon sheet is a specific tool with its own limitations and safety considerations.

The Risk of Overheating and Fumes

Teflon (PTFE) is safe within its recommended temperature range. However, if heated far beyond its limit (typically above 350°C / 662°F), it can begin to decompose and release toxic fumes.

Always operate your heat press within the recommended temperature guidelines for your materials and ensure your workspace is well-ventilated. This is a standard safety measure for all heat-related craft and production work.

Not a Substitute for Correct Settings

A Teflon sheet is a tool to enhance a good process; it is not a magic fix for incorrect temperature or pressure.

If your temperature is too high or your pressure is too strong, you can still damage your garment even with a Teflon sheet. It mitigates problems but does not eliminate the need for proper technique.

How to Apply This to Your Project

Use this guidance to align your Teflon sheet practices with your primary goal.

- If your primary focus is achieving the highest quality finish: Keep your sheet immaculately clean and replace it at the very first sign of wear, discoloration, or surface damage.

- If your primary focus is extending the life of your equipment: Make it a non-negotiable rule to always use a Teflon sheet to prevent any ink or adhesive residue from ever touching the heat platen.

- If your primary focus is cost-effectiveness: Invest in a quality, thicker sheet from the start, store it correctly to prevent creases, and clean it gently to maximize its operational lifespan.

By treating your Teflon sheet as a precision tool, you ensure every project meets a professional standard.

Summary Table:

| Best Practice | Key Action | Benefit |

|---|---|---|

| Prevent Scorching | Use as a protective shield between platen and project. | Avoids fabric damage and transfer discoloration. |

| Ensure Even Heat | Place sheet over entire design before pressing. | Eliminates hot spots for uniform adhesion. |

| Protect Equipment | Create a non-stick barrier to block residue transfer. | Keeps heat platen clean and extends its lifespan. |

| Maintain Sheet | Store flat/rolled, clean with damp cloth, replace when worn. | Maximizes sheet longevity and project consistency. |

Achieve professional heat press results with precision-engineered PTFE sheets from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated Teflon components—including seals, liners, and labware—are manufactured to the highest standards of durability and thermal resistance. From prototypes to high-volume orders, we ensure your projects are protected and your equipment lasts longer.

Ready to enhance your process? Contact our experts today for a consultation on the right PTFE solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How is PTFE used in sports rehabilitation and medical devices? Unlock Superior Biocompatibility and Performance

- What tools and coolants are recommended for machining Teflon (PTFE)? Achieve Clean, Precise Cuts

- How is virgin PTFE processed into sheets? A Guide to Purity, Performance, and Trade-offs

- What temperature range can expanded PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- How do PTFE expansion bellows compare to rubber bellows in terms of chemical resistance? PTFE Offers Near-Universal Chemical Resistance

- How can Teflon (PTFE) be processed into parts? A Guide to Compression Molding & CNC Machining

- What are the key properties of EPTFE gaskets? Superior Sealing for Extreme Conditions