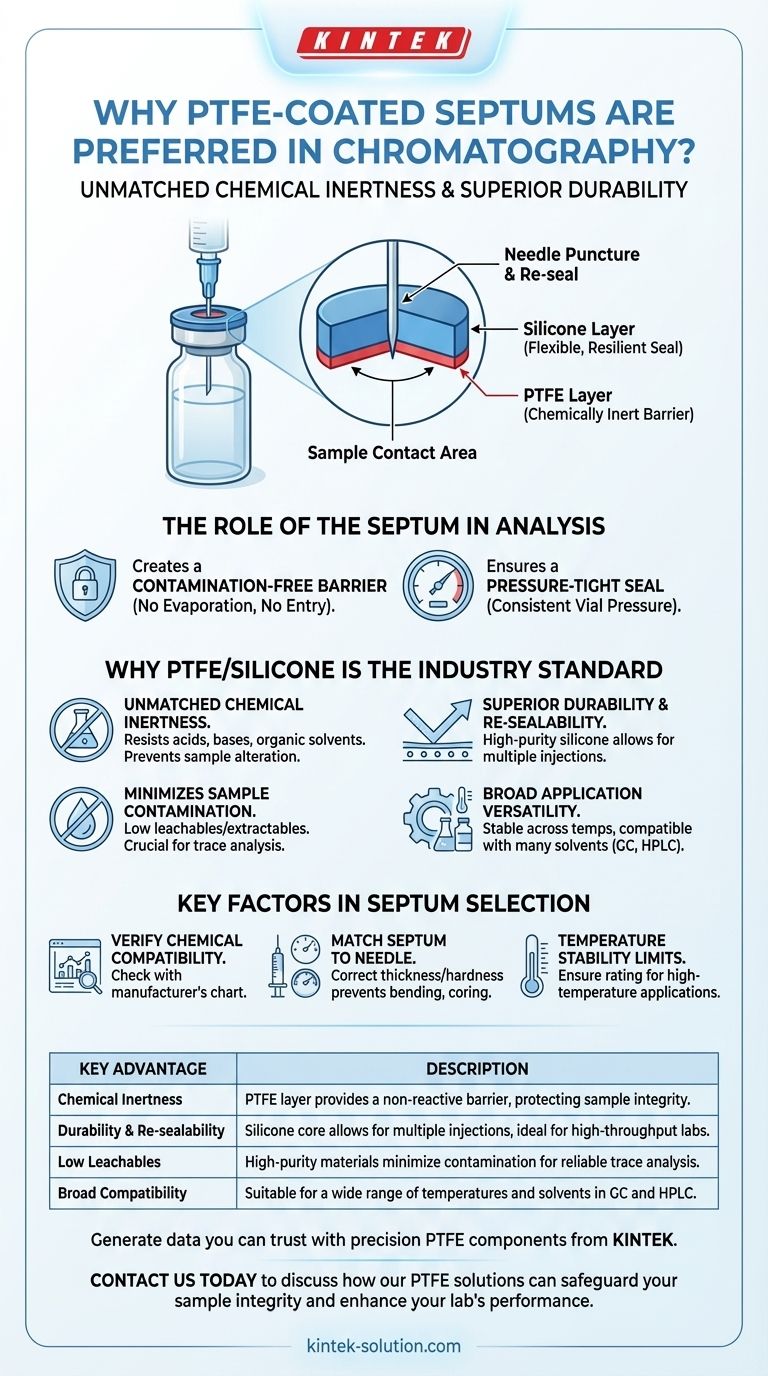

At its core, PTFE-coated septums are preferred in chromatography because their unique two-part construction provides exceptional chemical inertness while maintaining the physical durability and re-sealability required for modern analytical instruments. The PTFE layer acts as a chemically pure barrier protecting the sample, while the silicone layer provides the flexible, resilient seal.

The decision to use a PTFE-coated septum is not merely about closing a vial; it's a critical measure to safeguard sample integrity, prevent contamination, and ensure the accuracy and reproducibility of your analytical results.

The Role of the Septum in Analysis

A septum's job seems simple: to create a seal on a sample vial that a syringe needle can pierce for sample injection. However, this small component is central to maintaining the controlled environment necessary for high-precision chromatography.

Creating a Contamination-Free Barrier

The primary function is to isolate the sample from the outside environment. It must prevent both sample evaporation and the entry of atmospheric contaminants.

Ensuring a Pressure-Tight Seal

In many applications, particularly gas chromatography (GC), maintaining consistent pressure inside the vial is essential. A reliable septum ensures the system remains pressurized after injection.

Why PTFE/Silicone is the Industry Standard

The combination of Polytetrafluoroethylene (PTFE) and silicone creates a septum that excels in virtually every critical performance area. The two materials work in concert, each providing a distinct advantage.

Unmatched Chemical Inertness

The sample only ever makes contact with the PTFE layer. This material is renowned for its extreme chemical resistance, refusing to react with acids, bases, or the vast majority of organic solvents. This inertness is crucial for preventing the septum from altering the sample's chemical composition, which would compromise the analysis.

Superior Durability and Re-sealability

The bulk of the septum is made of high-purity silicone. This material provides excellent elasticity, allowing it to re-seal effectively after being punctured by a needle. This robustness allows for multiple injections from the same vial, a vital feature for high-throughput labs and automated systems.

Minimizing Sample Contamination

A poorly designed septum can introduce contaminants into your sample through a process called leaching or extractables. The high-purity materials used in PTFE/silicone septums are designed to minimize this risk, ensuring that the only peaks you see in your chromatogram come from your sample, not your vial cap. This is especially critical in trace analysis.

Broad Application Versatility

This composite structure is stable across a wide range of temperatures and compatible with countless solvents. This makes it the go-to choice for an array of techniques, from high-temperature GC to various High-Performance Liquid Chromatography (HPLC) methods.

Key Factors in Septum Selection

While PTFE/silicone is the default choice for most applications, understanding the nuances of selection ensures optimal performance and prevents costly failures.

Verifying Chemical Compatibility

Despite its excellent resistance, you should always verify that PTFE is compatible with the specific, and potentially aggressive, chemicals used in your analysis. A compatibility chart from the manufacturer is the best resource for this.

Matching Septum to Needle

The thickness and hardness of the septum should be appropriate for the needle gauge of your autosampler or syringe. Using too thick a septum or too fine a needle can lead to needle bending, poor sealing, or coring (where a piece of the septum is sheared off into the vial).

Temperature Stability Limits

Every septum has an operational temperature range. For high-temperature GC applications, ensure the selected septum is rated to withstand the temperatures of your inlet without degrading, which could lead to system contamination.

Making the Right Choice for Your Analysis

Your specific analytical goal should guide your final selection.

- If your primary focus is high-throughput screening: Prioritize a septum known for its durability and reliable re-sealability to accommodate many repeated injections without failure.

- If your primary focus is trace-level analysis: Select a septum certified for low leachables and extractables to guarantee the highest level of sample purity.

- If your primary focus is methods development: A general-purpose PTFE/silicone septum offers the widest versatility for experimenting with different solvents and temperature conditions.

Choosing the correct septum is a foundational step in generating data you can trust.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | PTFE layer provides a non-reactive barrier, protecting sample integrity. |

| Durability & Re-sealability | Silicone core allows for multiple injections, ideal for high-throughput labs. |

| Low Leachables | High-purity materials minimize contamination for reliable trace analysis. |

| Broad Compatibility | Suitable for a wide range of temperatures and solvents in GC and HPLC. |

Generate data you can trust with precision PTFE components from KINTEK.

The right septum is critical for accurate chromatography. As a leading manufacturer of high-purity PTFE components for the semiconductor, medical, and laboratory industries, we understand these precision needs. We offer custom fabrication of PTFE seals, liners, and labware—from prototypes to high-volume orders—to ensure your analytical processes are protected from contamination.

Contact us today to discuss how our PTFE solutions can safeguard your sample integrity and enhance your lab's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- How should PTFE plugs be handled with corrosive liquids? Prevent Costly Glassware Damage

- Why is temperature stability important for PTFE silicone septas in pharmaceutical processes? Ensure Data Integrity & Sample Safety

- What medical applications does Teflon have? Unlocking Biocompatibility and Performance

- Why should PTFE plugs not be used for long-term storage of liquids that attack glass? Avoid Dangerous Seal Failure

- What are PTFE stirring shafts and what styles are available? Select the Right Impeller for Your Lab

- What types of PTFE labware are commonly available? Find the Right Tools for Your Lab

- How is PTFE used in laboratory settings? Essential for Chemical Resistance and Sample Purity

- How does the transparency feature of PTFE vials aid in laboratory work? Enhance Visibility and Efficiency