When using liquids corrosive to glass with PTFE stopcocks, you must immediately and thoroughly rinse the entire stopcock assembly with water after use. This simple step is critical to prevent the corrosive liquid from evaporating and concentrating at the seal. The resulting high-concentration solution will chemically attack the glass barrel, leading to equipment damage, leaks, and potential safety hazards.

The chemical inertness of PTFE can create a false sense of security. The true risk lies not with the plug itself, but with how corrosive liquids concentrate at the glass-PTFE interface, attacking the glass barrel and ultimately compromising the entire seal.

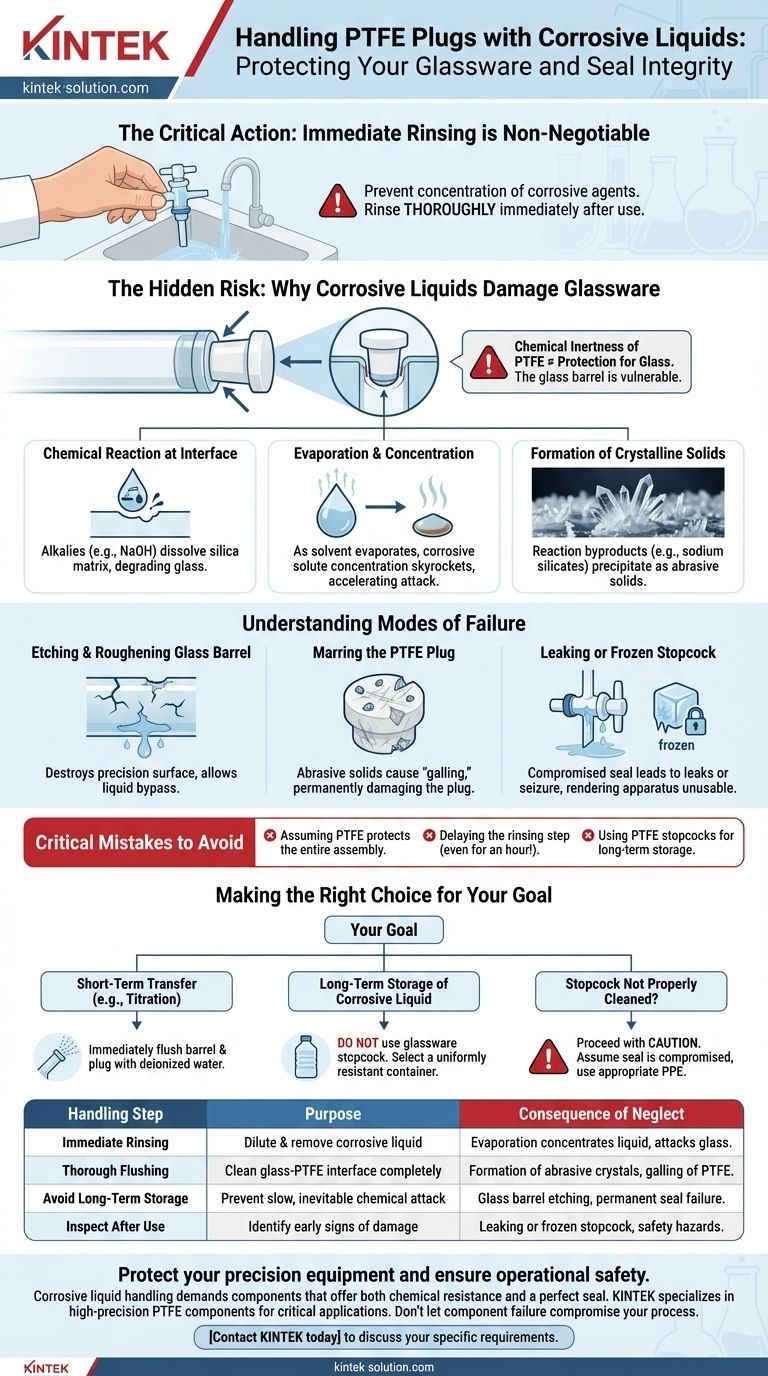

The Hidden Risk: Why Corrosive Liquids Damage Glassware

The Chemical Reaction at the Interface

While the PTFE plug is exceptionally non-reactive, the glass barrel it sits in is not. Borosilicate glass is vulnerable to attack by strong alkaline solutions (alkalies) and other corrosive agents.

This attack is a chemical reaction where the alkali, such as sodium hydroxide, dissolves the silica matrix of the glass. The smooth, polished surface of the barrel begins to degrade on a microscopic level.

The Dangers of Evaporation and Concentration

The most significant damage occurs when the liquid is allowed to sit in the stopcock. As the solvent (e.g., water) evaporates, the concentration of the corrosive solute skyrockets.

A dilute solution that might have a negligible effect over a short period can become intensely corrosive as it concentrates, dramatically accelerating the chemical attack on the glass.

Formation of Crystalline Solids

As the corrosive liquid reacts with the glass and the solvent evaporates, the dissolved salts and reaction byproducts (like sodium silicates) can precipitate out of the solution.

These hard, crystalline solids deposit directly onto the surfaces of both the glass barrel and the PTFE plug.

Understanding the Modes of Failure

Etching and Roughening the Glass Barrel

The primary mode of failure is the chemical etching of the glass barrel. This process destroys the precision-ground, smooth surface required for a liquid-tight seal.

The result is a roughened surface filled with microscopic pits and channels, which allows liquid to bypass the seal.

Marring the PTFE Plug

The crystalline solids that form are often abrasive. When you then attempt to rotate the stopcock, these trapped crystals act like sandpaper.

They grind against the relatively soft surface of the PTFE plug, creating scratches and gouges. This process, known as galling, permanently damages the plug and further compromises the seal.

The Leaking or "Frozen" Stopcock

A stopcock with a roughened glass barrel and a marred PTFE plug can no longer form a perfect seal. This leads to two critical problems.

First, the stopcock will begin to leak, creating a hazardous situation where corrosive chemicals can escape. Second, the combination of a rough glass surface and abrasive crystals can cause the plug to seize, or "freeze," in place, rendering the apparatus unusable.

The Critical Mistake to Avoid

Assuming PTFE Protects the Glass

The most common mistake is assuming the inertness of the PTFE plug extends to the entire assembly. The point of contact between the plug and the barrel is the most vulnerable part of the system when corrosive liquids are present.

Delaying the Rinsing Step

Damage is not instantaneous, but it begins the moment evaporation starts. Waiting even an hour before rinsing can be enough to allow concentration and initiate the chemical attack. Immediate rinsing after use is non-negotiable.

Using PTFE for Long-Term Storage

Glassware with PTFE stopcocks is fundamentally unsuitable for the long-term storage of liquids known to attack glass. The slow but inevitable chemical attack on the barrel's surface will eventually cause the seal to fail. This is a question of when, not if.

Making the Right Choice for Your Goal

To ensure the safety and integrity of your work, your handling procedure must match your application.

- If your primary focus is a short-term transfer (e.g., a titration): Immediately after use, flush the stopcock barrel and plug thoroughly with deionized water to remove any trace of the corrosive agent.

- If your primary focus is long-term storage of a corrosive liquid: Do not use glassware with a stopcock. Select a container made of a uniformly resistant material, such as a suitable polymer bottle with a solid, non-sealing cap.

- If you discover a stopcock that was not properly cleaned: Proceed with extreme caution. Assume the seal is compromised and the plug may be seized. Wear appropriate PPE before attempting to manipulate it.

Proper handling transforms a potential point of failure into a reliable and long-lasting component of your apparatus.

Summary Table:

| Handling Step | Purpose | Consequence of Neglect |

|---|---|---|

| Immediate Rinsing | Dilute and remove corrosive liquid | Evaporation concentrates liquid, attacks glass |

| Thorough Flushing | Clean glass-PTFE interface completely | Formation of abrasive crystals, galling of PTFE |

| Avoid Long-Term Storage | Prevent slow, inevitable chemical attack | Glass barrel etching, permanent seal failure |

| Inspect After Use | Identify early signs of damage | Leaking or frozen stopcock, safety hazards |

Protect your precision equipment and ensure operational safety.

Corrosive liquid handling demands components that offer both chemical resistance and a perfect seal. KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical interface between materials and the importance of durability. Whether you need reliable standard parts or custom-fabricated solutions from prototypes to high-volume orders, our focus on precision production ensures optimal performance and longevity for your demanding applications.

Don't let component failure compromise your process. Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can provide a robust solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key properties of PTFE for sanitary gaskets? Ensuring Purity & Safety in Food & Pharma

- Which chemicals are fully compatible with PTFE filters? Discover Unmatched Chemical Resistance

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What are PTFE silicone septas and their role in the pharmaceutical industry? Ensure Sample Integrity and Accurate Analysis

- What are the advantages of the PTFE bottle's non-stick surface? Ensure Purity and Efficiency in Your Lab

- How do PTFE syringe filters compare to membrane filters? A Guide to Chemical Compatibility

- How can PTFE/silicone septa potentially cause contamination in laboratory analyses? Ensure Sample Integrity with the Right Septa

- Why is consistent performance important in chromatography vials? Ensure Data Integrity and Reproducibility