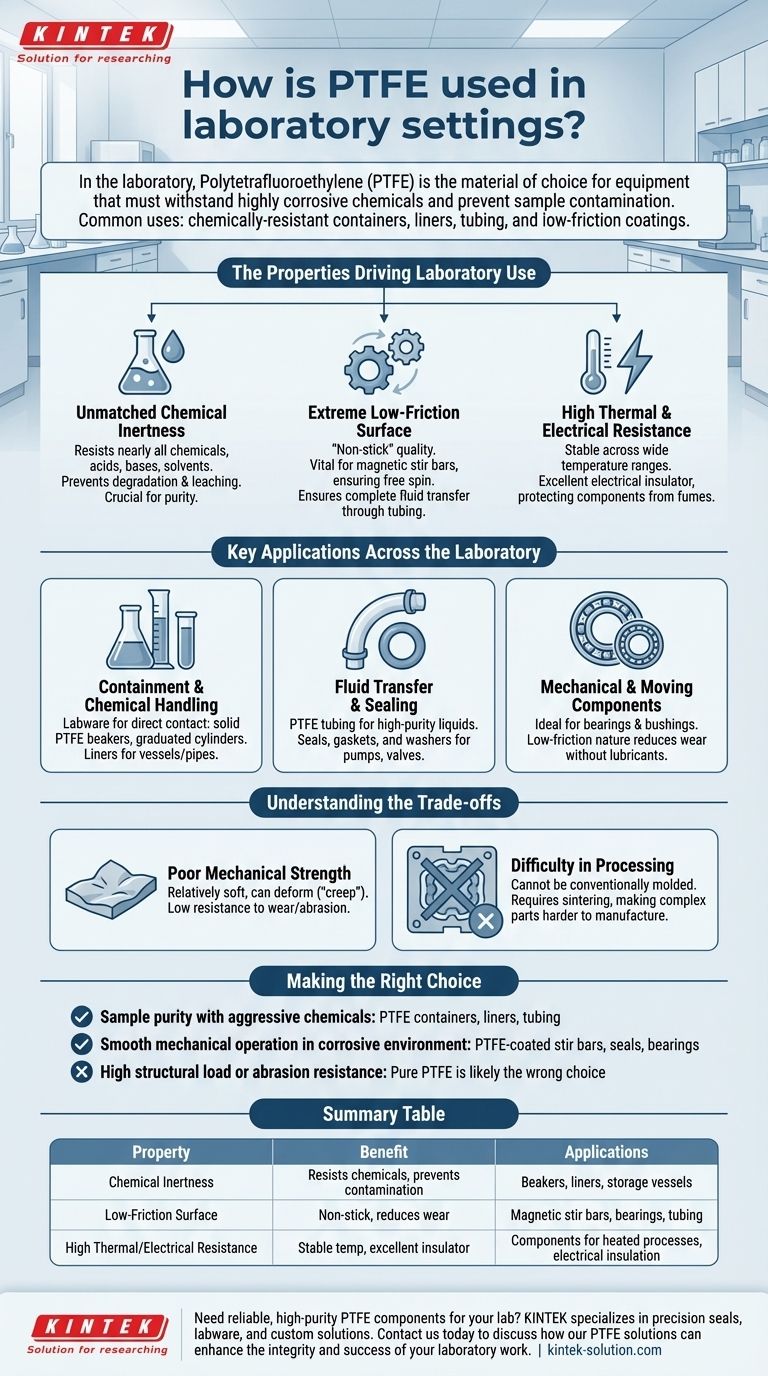

In the laboratory, Polytetrafluoroethylene (PTFE) is the material of choice for equipment that must withstand highly corrosive chemicals and prevent sample contamination. It is most commonly found in chemically-resistant containers like beakers, liners for vessels, tubing for fluid transfer, and as low-friction coatings on components like magnetic stir bars.

The core reason PTFE is indispensable in a lab setting is its unique combination of near-total chemical inertness and an extremely low-friction, non-stick surface. This ensures that experiments remain pure and equipment remains functional, even when exposed to the most aggressive substances.

The Properties Driving Laboratory Use

To understand PTFE's role, we must first look at the fundamental properties that make it so uniquely suited for demanding scientific environments. These characteristics solve common laboratory challenges related to reactivity, purity, and equipment failure.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all chemicals, including aggressive acids, bases, and organic solvents. This property is its single most important attribute for lab work.

This inertness prevents the material from degrading or leaching contaminants into a sample, which is critical for maintaining the purity and accuracy of an experiment. This is why it is used to construct or line beakers, flasks, and storage vessels.

Extreme Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality.

In the lab, this is crucial for components like magnetic stir bars, allowing them to spin freely without grabbing or sticking. It also ensures the complete and easy transfer of fluids through PTFE tubing, minimizing sample loss.

High Thermal and Electrical Resistance

PTFE remains stable across a very wide range of temperatures, making it suitable for both cryogenic applications and heated processes.

Furthermore, it is an excellent electrical insulator. This makes it a valuable material in laboratory instruments where electrical components might be exposed to corrosive chemical fumes.

Key Applications Across the Laboratory

These core properties translate directly into specific, critical applications that are common in almost any chemistry, biology, or materials science lab.

Containment and Chemical Handling

The most visible use of PTFE is in labware designed for direct contact with chemicals. This includes solid PTFE beakers, graduated cylinders, and funnels.

More commonly, it is used as a liner for vessels or pipes. This provides the chemical resistance of solid PTFE at a lower cost and with the structural integrity of an outer material like steel or glass.

Fluid Transfer and Sealing

PTFE tubing is standard for transferring high-purity or corrosive liquids and gases. Its flexibility and non-reactive surface ensure that the substance being moved is not contaminated.

Within equipment like pumps, valves, and fittings, PTFE is used for seals, gaskets, and washers. Its softness allows it to create a tight seal, while its chemical resistance prevents it from being destroyed by the materials it contacts.

Mechanical and Moving Components

For equipment with moving parts, such as mixers, pumps, or centrifuges, PTFE serves as an ideal material for bearings and bushings.

Its low-friction nature reduces wear and allows for smooth operation without lubricants, which could otherwise become a source of contamination.

Understanding the Trade-offs

No material is perfect, and relying on PTFE requires an understanding of its limitations. Acknowledging these trade-offs is essential for proper application and avoiding experimental failure.

Poor Mechanical Strength

PTFE is a relatively soft material. It can deform under constant pressure (a phenomenon known as "creep") and has low resistance to wear and abrasion compared to harder plastics.

This makes it unsuitable for high-load structural applications unless it is reinforced with other materials like glass fiber or carbon.

Difficulty in Processing

PTFE cannot be processed using conventional melt-extrusion or injection molding techniques that are common for other thermoplastics.

It must be compressed and sintered from a powder, which makes the manufacturing of complex parts more difficult and expensive.

Making the Right Choice for Your Goal

Selecting the correct material is fundamental to successful and repeatable science. Your choice should be guided by the primary demand of your application.

- If your primary focus is sample purity with aggressive chemicals: PTFE containers, liners, and tubing are the industry standard and the safest choice.

- If your primary focus is smooth mechanical operation in a corrosive environment: Use PTFE-coated stir bars and PTFE seals, gaskets, or bearings in your equipment.

- If your primary focus is high structural load or abrasion resistance: Pure PTFE is likely the wrong choice; consider a reinforced PTFE composite or an entirely different polymer.

By understanding its core properties and limitations, you can leverage PTFE as a powerful tool for ensuring the integrity and success of your laboratory work.

Summary Table:

| Property | Benefit in the Lab | Common Applications |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents contamination | Beakers, liners, storage vessels |

| Low-Friction Surface | Non-stick, reduces wear on moving parts | Magnetic stir bars, bearings, tubing |

| High Thermal/Electrical Resistance | Stable across wide temperature ranges; excellent insulator | Components for heated processes, electrical insulation |

Need reliable, high-purity PTFE components for your lab?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures your equipment meets the highest standards for chemical resistance and contamination control.

Contact us today to discuss how our PTFE solutions can enhance the integrity and success of your laboratory work.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the benefits of using a PTFE safety cover? Enhance Safety, Cut Costs & Mitigate Hazards

- What are the key properties of PTFE that make it suitable for chromatography septums? Ensure Sample Integrity and Reliable Results

- How does the manufacturer's reputation and quality assurance impact the choice of a PTFE-coated septum? Ensure Data Integrity

- What are some specific applications of PTFE shovels in the laboratory? Ensure Sample Purity and Safety

- What steps are involved in selecting the proper PTFE filter? A 4-Step Guide to Optimal Filtration

- What are the advantages of using PTFE stirrers and shafts in corrosive applications? Ensure Purity and Reliability

- How do PTFE and silicone septa compare in terms of temperature range? Choosing the Right Septa for Your Lab

- What is the advantage of using PTFE ferromagnetic support discs? Achieve Flawless, Efficient Sample Preparation