In short, PTFE bushes are suitable for high-temperature environments because of their fundamental material properties. They possess a high melting point of around 327°C (621°F) and excellent thermal stability, allowing them to maintain their strength, shape, and low-friction characteristics without degrading under heat that would cause metals to deform or conventional lubricants to fail.

The true advantage of PTFE in high-temperature applications is not just its heat resistance, but its unique combination of thermal stability and inherent self-lubrication. This pairing solves two problems at once: the material endures the heat, and it provides its own lubrication when traditional greases would burn away.

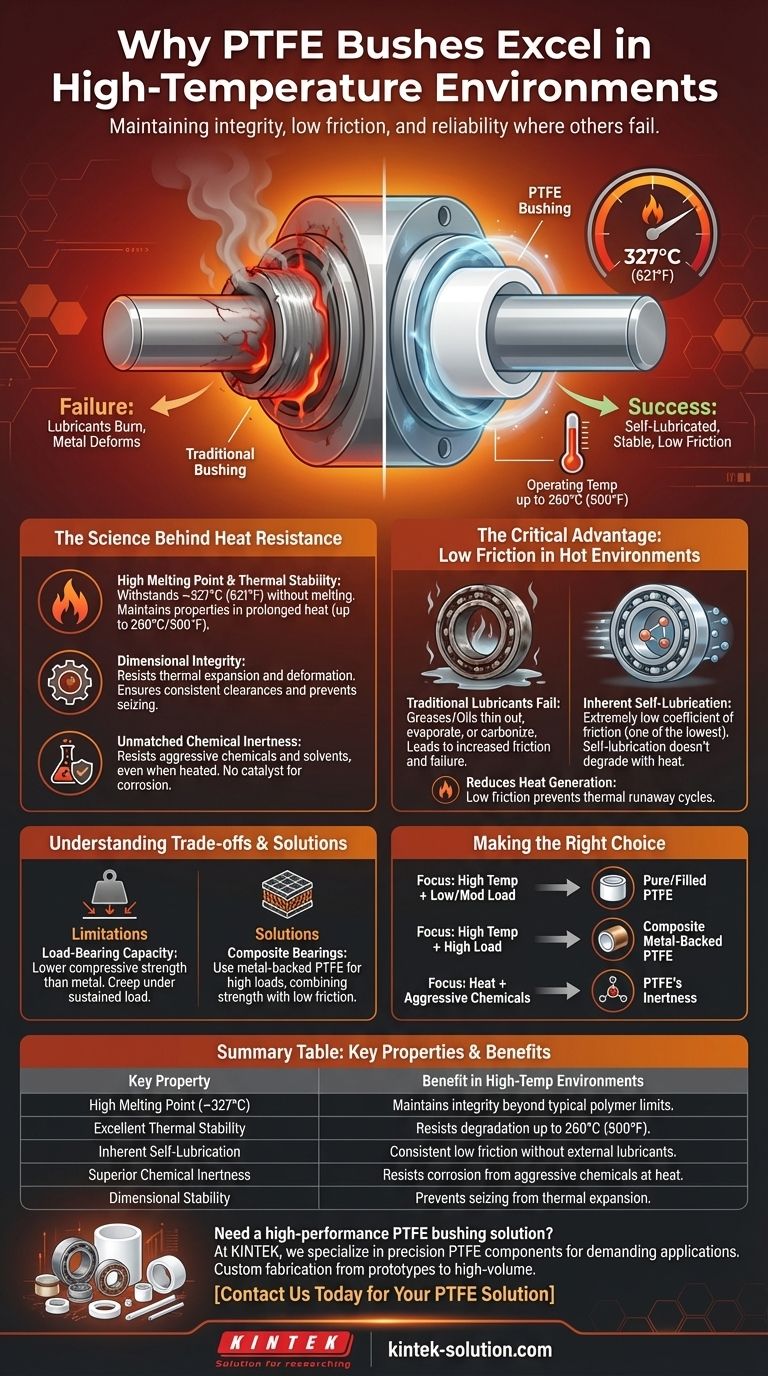

The Science Behind PTFE's Heat Resistance

To understand why PTFE (Polytetrafluoroethylene) excels where other materials falter, we need to look at its core characteristics. Its performance is not based on a single trait but on the interplay of several key properties.

High Melting Point and Thermal Stability

PTFE has a very high melting point for a polymer, approximately 327°C (621°F).

More importantly, it exhibits exceptional thermal stability. This means it can withstand repeated or prolonged exposure to high operating temperatures (typically up to 260°C or 500°F) without breaking down or losing its essential properties.

Maintaining Dimensional Integrity

A common failure point for components in hot environments is thermal expansion. Metals can expand and deform, causing clearances to change and parts to seize.

PTFE maintains its dimensional stability well under thermal stress. This ensures that the bushing continues to function reliably with consistent clearances, preventing failures related to heat-induced deformation.

Unmatched Chemical Inertness

High temperatures often act as a catalyst, accelerating chemical reactions and corrosion.

PTFE is one of the most chemically inert substances known. It resists virtually all industrial chemicals and solvents, a property that does not diminish as temperatures rise, making it ideal for harsh chemical environments that are also hot.

Why Low Friction is a Critical Advantage in Hot Environments

Heat resistance alone is only part of the equation for a good bushing. The way a material manages friction is equally important, especially when it gets hot.

The Failure of Traditional Lubricants

Many standard bushings rely on grease or oil for lubrication. At high temperatures, these lubricants can thin out, evaporate, or carbonize (burn), losing their effectiveness entirely.

This loss of lubrication leads to increased friction, which generates even more heat and can cause catastrophic component failure.

Inherent Self-Lubricating Performance

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. It is self-lubricating.

This property is part of the material itself and does not degrade with heat. The bushing remains low-friction and operational long after traditional lubricants would have failed, drastically reducing maintenance and improving reliability.

Reducing Frictional Heat Generation

Because PTFE creates so little friction, the bushing itself generates less heat during operation.

This prevents a thermal runaway cycle where friction creates heat, which breaks down lubricants, which in turn leads to more friction and more heat.

Understanding the Trade-offs

While exceptional, PTFE is not a universal solution. An objective analysis requires understanding its limitations.

Load-Bearing Capacity

As a polymer, pure PTFE has a lower compressive strength than metal bushes like bronze or steel. It is not suitable for extremely high-load applications on its own.

For such scenarios, composite bearings (e.g., bronze-backed PTFE) are used to combine the strength of a metal shell with the low-friction surface of a PTFE liner.

Creep or "Cold Flow"

Under a sustained load, especially when warm, PTFE can slowly deform over time. This phenomenon, known as creep, must be factored into the design phase for long-term applications under constant pressure.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to the primary demands of your environment.

- If your primary focus is high temperature with low to moderate loads: A pure PTFE or filled-PTFE bushing is an excellent choice, offering superior stability and self-lubrication.

- If your primary focus is high temperature combined with high mechanical loads: You should specify a composite metal-backed PTFE bushing to get the necessary structural strength.

- If your primary focus is a combination of heat and aggressive chemicals: PTFE's chemical inertness makes it one of the few materials that can reliably perform under such demanding conditions.

By understanding these core principles, you can confidently leverage PTFE's unique properties in designs where heat and friction would cause conventional materials to fail.

Summary Table:

| Key Property | Benefit in High-Temperature Environments |

|---|---|

| High Melting Point (~327°C / 621°F) | Maintains integrity and shape far beyond typical polymer limits. |

| Excellent Thermal Stability | Resists degradation and maintains properties up to 260°C (500°F). |

| Inherent Self-Lubrication | Provides consistent low friction without external lubricants that fail. |

| Superior Chemical Inertness | Resists corrosion from aggressive chemicals, even at high temperatures. |

| Dimensional Stability | Prevents seizing and failure due to thermal expansion. |

Need a high-performance PTFE bushing solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom bushings—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver reliable thermal stability, self-lubrication, and chemical resistance, even in the most extreme environments.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications.

Contact us today to discuss how our PTFE solutions can enhance your project's reliability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the flexibility of PTFE expansion bellows benefit industrial piping systems? Absorb Stress, Prevent Failure

- How do PTFE seals contribute to reducing vehicle emissions? Achieve Cleaner, More Efficient Vehicles

- How can Teflon packing be enhanced for specific applications? Tailor PTFE for Superior Performance

- What types of industrial applications are Teflon Bellow Mechanical Seals best suited for? Excel in Harsh Chemical & High-Speed Environments

- What materials are used to manufacture PTFE wear strips and bands? Choose the Right Filler for Your Application

- How can wear and tear in PTFE butterfly valves be addressed? Prevent Failures and Extend Valve Life

- Why are Teflon bushings suitable for food processing applications? Ensure Food Safety and Efficiency

- How easy is it to install expanded PTFE gaskets? Achieve a Perfect Seal with Minimal Effort