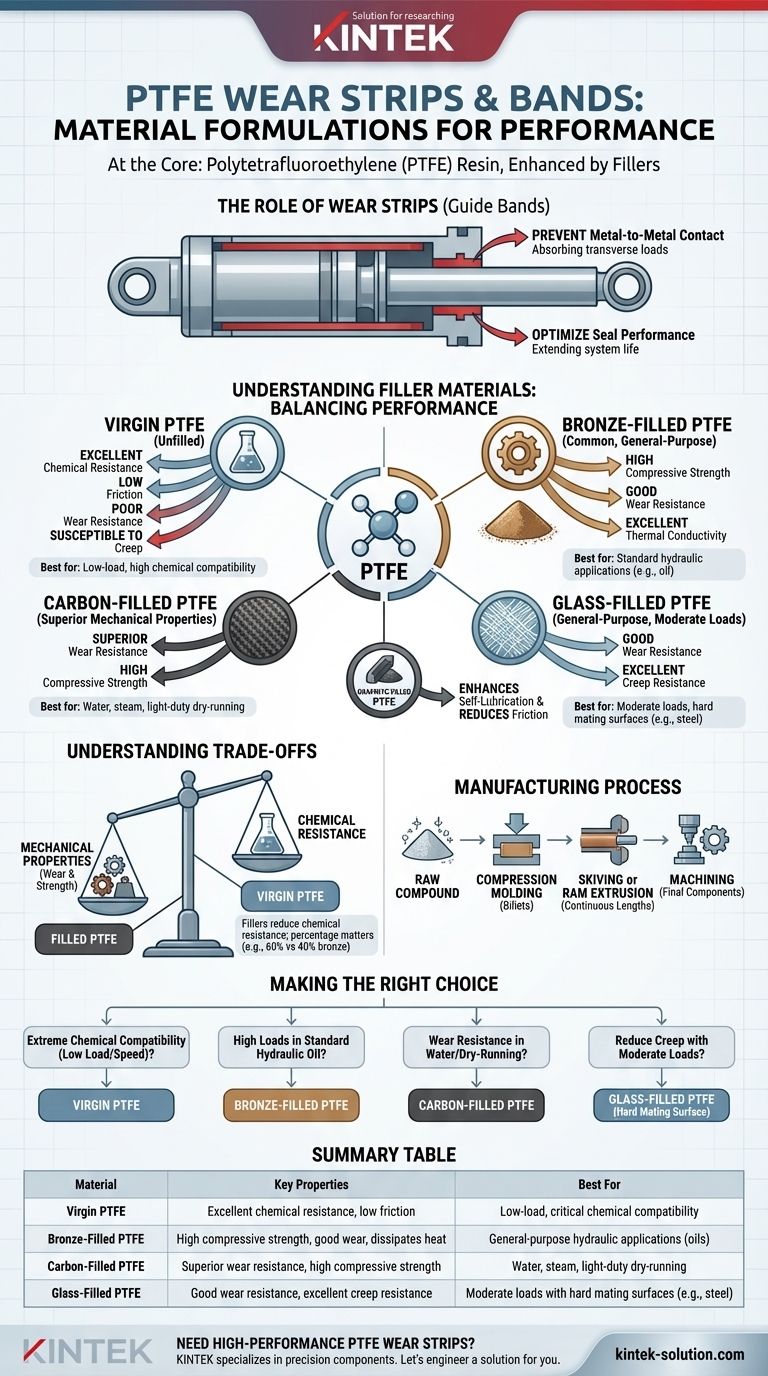

At its core, PTFE wear strips and bands are manufactured from Polytetrafluoroethylene (PTFE) resin. However, to enhance performance for specific applications, this base resin is almost always blended with filler materials. The most common formulations include Virgin (unfilled) PTFE, Bronze-Filled PTFE, and Carbon-Filled PTFE, along with other specialized grades like glass or graphite-filled PTFE.

The key takeaway is not the base PTFE, but the filler material blended into it. While Virgin PTFE offers exceptional chemical resistance and low friction, fillers are essential for improving critical mechanical properties like wear resistance, compressive strength, and resistance to deformation under load.

The Role of PTFE Wear Strips

Wear strips, also known as guide bands or bearing strips, serve a critical function in dynamic systems like hydraulic and pneumatic cylinders.

Preventing Metal-to-Metal Contact

Their primary purpose is to guide the piston and rod, preventing direct contact between moving metal components. This absorbs transverse loads and protects the system from scoring and premature failure.

Optimizing Seal Performance

By maintaining precise alignment, wear strips ensure that the primary seals (like piston seals and rod seals) operate under optimal conditions, extending the life and reliability of the entire sealing system.

Understanding the Material Formulations

The choice of material is a critical design decision based on the application's operating pressure, temperature, fluid media, and speed.

Virgin PTFE

This is pure, unfilled Polytetrafluoroethylene. It is selected for its unmatched chemical inertness and extremely low coefficient of friction.

However, it has poor wear resistance and is susceptible to creep—the tendency to deform permanently under a sustained load. It is best suited for low-load applications where chemical compatibility is the top priority.

Bronze-Filled PTFE

This is the most common material for general-purpose hydraulic applications. Bronze powder (typically 40% or 60% by weight) is blended with the PTFE resin.

Adding bronze significantly increases compressive strength and thermal conductivity, allowing heat to dissipate from the bearing surface more effectively. This results in higher load-bearing capacity and better wear resistance compared to virgin PTFE.

Carbon-Filled PTFE

Carbon, often in powder or fiber form, is added to PTFE to enhance its mechanical properties.

Carbon-filled grades offer excellent wear resistance and high compressive strength, often superior to bronze-filled variants. They are particularly effective in water, steam, and light-duty dry-running applications where bronze is unsuitable.

Glass-Filled PTFE

Adding glass fibers improves wear properties and provides exceptional resistance to creep. It is a good general-purpose filler for moderate load applications.

However, glass fibers can be abrasive to softer mating surfaces like aluminum or brass, so the hardware's material must be considered during design.

Graphite-Filled PTFE

Graphite is sometimes added, often in combination with other fillers like carbon or glass. Its primary contribution is enhancing the material's self-lubricating properties and reducing the coefficient of friction, especially during initial startup.

Understanding the Trade-offs

Selecting a filled PTFE compound is always an exercise in balancing competing properties. There is no single "best" material for all situations.

The Core Trade-off: Mechanical vs. Chemical Properties

Adding fillers like bronze, carbon, or glass dramatically improves mechanical characteristics such as wear resistance and compressive strength.

However, these fillers almost always reduce the chemical resistance of the compound compared to Virgin PTFE. For instance, bronze-filled PTFE is not suitable for use with certain chemicals or in saltwater applications where bronze can corrode.

Filler Percentage Matters

The percentage of the filler is a key variable. For example, a 60% bronze-filled PTFE will have higher compressive strength and wear resistance than a 40% bronze-filled grade, but it will also be denser and potentially less chemically resistant.

The Manufacturing Process

The raw, blended PTFE compound is transformed into wear strips through processes like compression molding to form billets, followed by skiving (peeling a thin layer from the billet) or ram extrusion to create continuous lengths. These lengths are then cut to size or machined on CNC lathes and mills to produce the final component.

Making the Right Choice for Your Application

Your selection should be guided by the most demanding aspect of your system's operating environment.

- If your primary focus is extreme chemical compatibility: Choose Virgin PTFE, but only for low-load and low-speed applications.

- If your primary focus is high loads in standard hydraulic oil: Bronze-filled PTFE is the industry standard and the most reliable starting point.

- If your primary focus is wear resistance in water or dry-running conditions: Carbon-filled PTFE provides superior performance and avoids the corrosion issues of bronze.

- If your primary focus is reducing creep with moderate loads: Glass-filled PTFE is an excellent choice, provided your mating hardware is a hard material like steel.

Ultimately, selecting the correct wear strip material is a critical step in engineering a reliable and long-lasting mechanical system.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Virgin PTFE | Excellent chemical resistance, low friction | Low-load applications where chemical compatibility is critical |

| Bronze-Filled PTFE | High compressive strength, good wear resistance, dissipates heat | General-purpose hydraulic applications with standard oils |

| Carbon-Filled PTFE | Superior wear resistance, high compressive strength | Water, steam, and light-duty dry-running applications |

| Glass-Filled PTFE | Good wear resistance, excellent creep resistance | Moderate loads with hard mating surfaces (e.g., steel) |

Need High-Performance PTFE Wear Strips?

Selecting the right material is critical for your system's reliability and longevity. KINTEK specializes in manufacturing precision PTFE components, including custom wear strips and bands for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs between chemical resistance, wear, and load capacity to deliver a solution optimized for your specific operating environment—from prototypes to high-volume production.

Let's engineer a solution for you. Contact our experts today to discuss your application requirements.

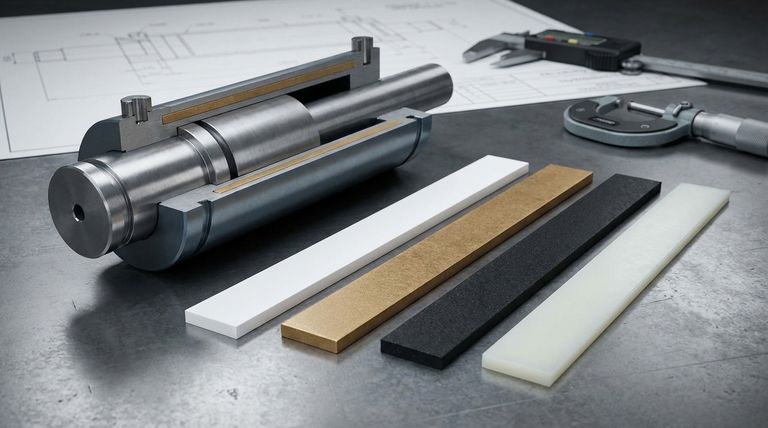

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments