Enhancing Teflon packing is a matter of strategic reinforcement. Pure Polytetrafluoroethylene (PTFE), known commercially as Teflon, offers exceptional chemical resistance and a low-friction surface. However, to optimize it for specific industrial challenges, it is commonly blended with other materials like graphite or constructed in specialized multi-yarn weaves to improve properties like heat dissipation and structural integrity.

Standard PTFE packing provides a superior chemical seal but can struggle under high pressure, high speed, or in abrasive conditions. Enhancing it involves adding fillers or structural components that compensate for PTFE's inherent limitations, allowing you to tailor the packing's performance to a specific operational environment.

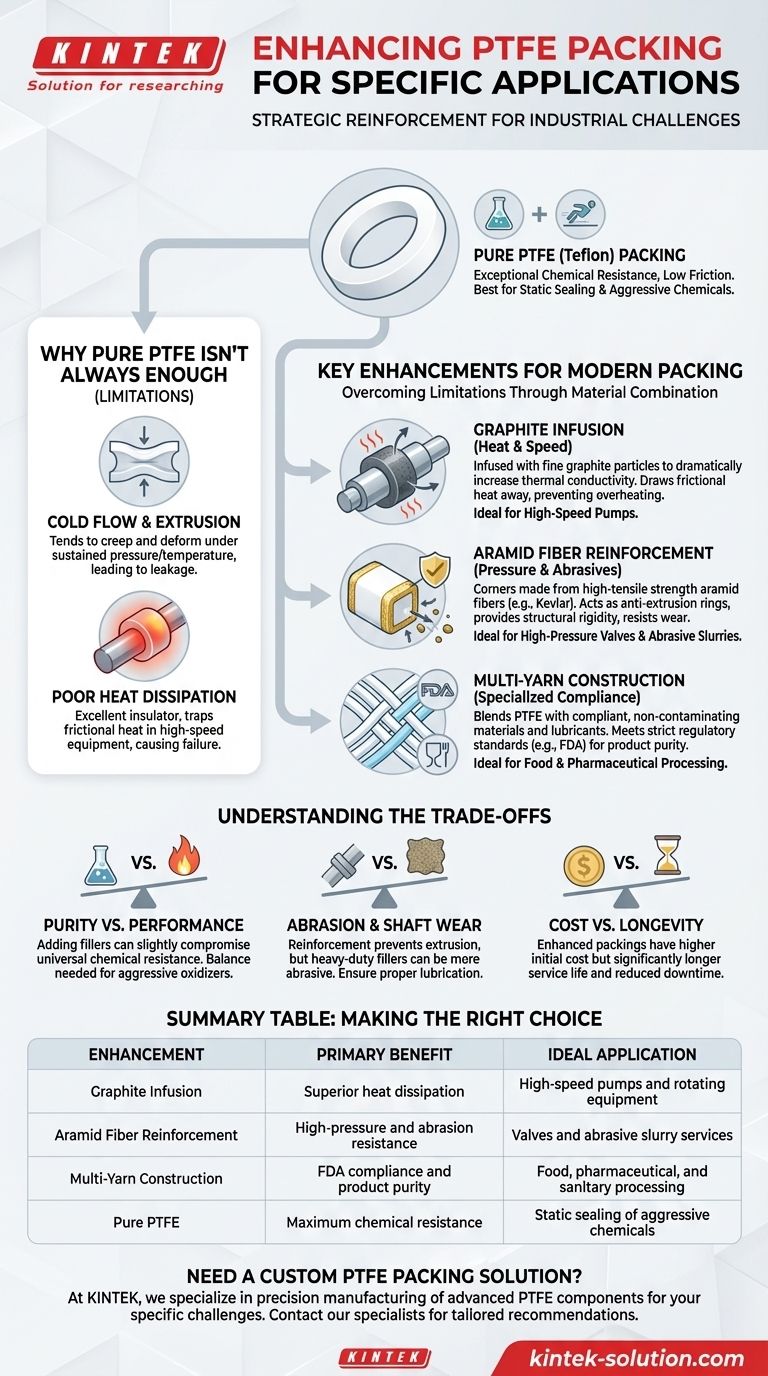

Why Pure PTFE Packing Isn't Always Enough

Pure PTFE is a remarkable material, but understanding its natural limitations is key to knowing when and why an enhanced version is necessary.

The Benefit: Unmatched Chemical Inertness

Pure PTFE packing is virtually immune to chemical attack across the entire 0-14 pH range, with the exception of molten alkali metals and elemental fluorine. This makes it a default choice for sealing aggressive chemicals in pipes, valves, and food processing equipment.

The Challenge: "Cold Flow" and Extrusion

A primary limitation of pure PTFE is its tendency to "cold flow," or creep. Under sustained pressure and temperature, the material can deform and extrude out of the stuffing box, leading to a loss of sealing pressure and eventual leakage.

The Problem: Poor Heat Dissipation

PTFE is an excellent insulator, which is a disadvantage in high-speed rotating equipment like pumps. It traps frictional heat at the shaft, which can cause the packing to expand, harden, or burn, leading to premature failure and potential shaft damage.

Key Enhancements for Modern Packing

To overcome these limitations, PTFE is combined with other materials. Each addition is chosen to impart a specific, desirable characteristic.

Graphite Infusion: For Heat and Speed

By infusing the PTFE fibers with fine graphite particles, the packing's thermal conductivity is dramatically increased. This enhancement is critical for high-speed pump applications.

Graphite acts as a pathway to draw frictional heat away from the rotating shaft and dissipate it through the stuffing box housing. This prevents overheating, reduces the need for extensive flush water, and extends the life of both the packing and the shaft.

Aramid Fiber Reinforcement: For Pressure and Abrasives

For high-pressure applications or when sealing abrasive slurries, PTFE packing is often constructed with corners made from aramid fibers (such as Kevlar).

These high-tensile strength fibers act as anti-extrusion rings. They provide structural rigidity, preventing the softer PTFE body from being forced out of the gland and providing superior resistance to wear from abrasive particles.

Multi-Yarn Construction: For Specialized Compliance

In sensitive industries like food processing and pharmaceuticals, packing must meet strict regulatory standards, such as those from the FDA.

Multi-yarn packings are designed to meet these requirements. They may blend PTFE with other compliant, non-contaminating materials and lubricants to ensure product purity while still delivering a reliable, long-lasting seal.

Understanding the Trade-offs

Choosing an enhanced packing involves balancing performance gains against other factors. There is no single "best" packing, only the right packing for the job.

Purity vs. Performance

Adding fillers like graphite can slightly compromise the universal chemical resistance of pure PTFE. While still highly resistant, a graphite-infused packing may not be suitable for extremely aggressive oxidizers that pure PTFE could handle.

Abrasion and Shaft Wear

While aramid corners prevent extrusion, some heavy-duty fillers like carbon fiber (another common enhancement) can be more abrasive than pure PTFE. Care must be taken to ensure proper lubrication and break-in procedures to avoid scoring a soft shaft sleeve.

Cost vs. Longevity

Enhanced packings are more expensive than their pure PTFE counterparts. However, this initial cost is often justified by significantly longer service life, reduced maintenance downtime, and less frequent damage to equipment.

Making the Right Choice for Your Application

Selecting the correct packing requires a clear understanding of your primary operational challenge.

- If your primary focus is high-speed pumps: Choose a graphite-infused PTFE packing to effectively manage heat buildup and prevent premature failure.

- If your primary focus is high-pressure valves or abrasive media: Select a packing with aramid-reinforced corners to prevent extrusion and resist wear.

- If your primary focus is food or pharmaceutical processing: Use a multi-yarn or pure PTFE packing specifically certified to meet FDA or other relevant sanitary standards.

- If your primary focus is static sealing of aggressive chemicals at low pressures: Pure, un-filled PTFE packing often remains the most reliable and cost-effective solution.

By matching the material's properties to the application's demands, you engineer a more reliable and resilient sealing system.

Summary Table:

| Enhancement | Primary Benefit | Ideal Application |

|---|---|---|

| Graphite Infusion | Superior heat dissipation | High-speed pumps and rotating equipment |

| Aramid Fiber Reinforcement | High-pressure and abrasion resistance | Valves and abrasive slurry services |

| Multi-Yarn Construction | FDA compliance and product purity | Food, pharmaceutical, and sanitary processing |

| Pure PTFE | Maximum chemical resistance | Static sealing of aggressive chemicals |

Need a custom PTFE packing solution for your specific challenge?

At KINTEK, we specialize in the precision manufacturing of advanced PTFE components, including custom packings, seals, and liners. Whether you're battling extreme pressures, abrasive slurries, or require FDA-compliant materials for sanitary applications, our experts can tailor a solution that enhances performance, extends equipment life, and reduces downtime.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact our sealing specialists today to discuss your application requirements and receive a tailored recommendation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What environmental concerns are associated with Teflon packing? The Hidden Cost of a Non-Biodegradable Seal

- What are the key properties of EPTFE gaskets? Superior Sealing for Extreme Conditions

- How do PTFE seals and rings contribute to environmental compliance? Ensure Leak-Proof Operations

- What makes PTFE lip seals suitable for aerospace applications? Unmatched Performance in Extreme Conditions

- What role does temperature stability play in PTFE coated fasteners? Ensuring Reliability in Extreme Environments

- What is the shelf life of PTFE O-rings? Unlock the Secret to Indefinite Storage Stability

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation

- What are the applications of PTFE in the chemical industry? A Guide to Superior Corrosion Resistance