In essence, the flexibility of PTFE expansion bellows is their primary functional benefit, allowing them to absorb multi-directional movements—axial, lateral, and angular—within a piping system. This capability directly protects pipes, flanges, and connected equipment from the damaging stresses caused by thermal expansion, mechanical vibration, and structural misalignment.

The core challenge in any industrial piping system is managing stress. The unique flexibility of a PTFE bellow acts as a purpose-built point of absorption, converting potentially destructive forces into harmless movement, thereby ensuring the system's safety, reliability, and longevity.

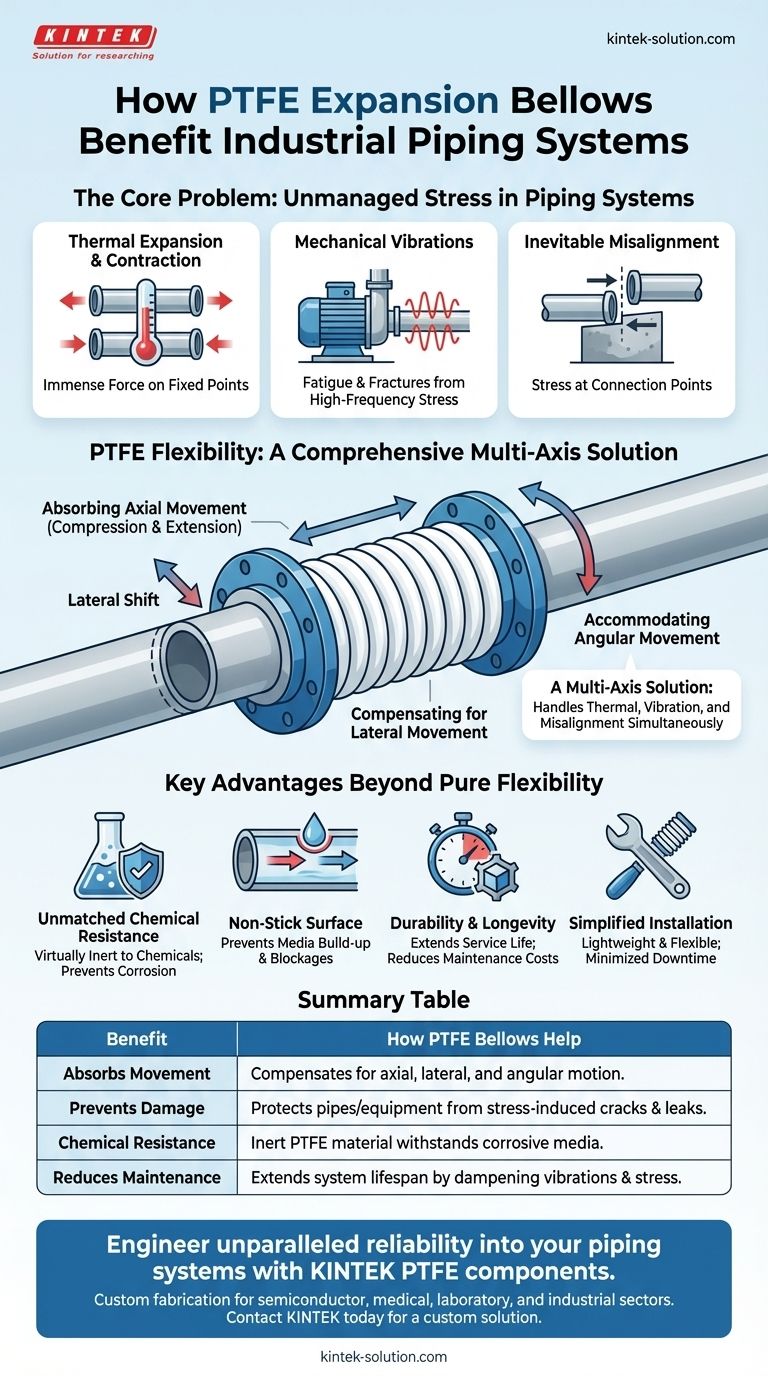

The Core Problem: Unmanaged Stress in Piping Systems

Industrial piping is rarely a static environment. Several constant forces introduce stress that, if left unmanaged, can lead to cracks, leaks, and catastrophic failure.

Thermal Expansion and Contraction

Piping systems expand when heated and contract when cooled. Over long runs, this thermal cycling can exert immense force on fixed points, such as connections to tanks or pumps.

Mechanical Vibrations

Equipment like pumps, compressors, and engines transmit vibrations directly into the piping. These constant, high-frequency stresses can fatigue metal components over time, leading to fractures.

Inevitable Misalignment

Perfect pipe alignment during installation is difficult and costly to achieve. Furthermore, foundations can settle and structures can shift over time, creating stress at connection points.

How PTFE Flexibility Provides a Comprehensive Solution

A PTFE expansion bellow is engineered to be the most flexible point in a rigid system, safely absorbing movement from these various sources. Its value lies in its ability to handle multiple types of motion simultaneously.

Absorbing Axial Movement

This is movement along the centerline of the pipe, either compression (pushing together) or extension (pulling apart). This is the primary motion caused by thermal expansion.

Compensating for Lateral Movement

This refers to a sideways or shearing motion, where one end of the bellow shifts perpendicular to the other. This often occurs due to misalignment or vibrations from connected equipment.

Accommodating Angular Movement

This is a bending or rotational motion, where the flanges of the bellow are no longer parallel. It is critical for absorbing stress from settling foundations or complex thermal growth.

A Multi-Axis Solution

Crucially, these forces rarely occur in isolation. A system might experience thermal expansion (axial) while a pump is running (lateral vibration) in a slightly misaligned section (angular). PTFE's inherent flexibility allows it to compensate for all these movements at once.

Key Advantages Beyond Pure Flexibility

While flexibility is the mechanical benefit, the material properties of PTFE are what make it suitable for demanding industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This prevents corrosion and material degradation, which would otherwise compromise the bellow and the entire system.

Non-Stick Surface

The non-stick properties of PTFE prevent media from building up inside the convolutions of the bellow. This ensures consistent flow rates and prevents blockages, a common problem in slurries or high-purity applications.

Durability and Longevity

By absorbing vibrations and stress, the bellow not only protects the surrounding pipe but also extends its own service life. This reduces the frequency of maintenance cycles and lowers long-term operational costs.

Simplified Installation

PTFE bellows are lightweight and flexible, making them significantly easier and faster to install than their rigid metal counterparts. This reduces labor costs and minimizes system downtime during installation or replacement.

Making the Right Choice for Your Application

Selecting the right component requires matching its strengths to your system's specific challenges.

- If your primary focus is handling aggressive chemicals: The near-universal chemical inertness of PTFE makes it the default choice for protecting your system from corrosive media.

- If your primary focus is absorbing thermal cycles: A PTFE bellow is an ideal solution for isolating sensitive equipment from the stress of pipe expansion and contraction.

- If your primary focus is dampening machine vibration: Placing a PTFE bellow near a pump or motor effectively isolates the rest of the piping from damaging vibrational energy.

Ultimately, integrating a PTFE expansion bellow is a proactive measure to engineer reliability directly into your piping system.

Summary Table:

| Benefit | How PTFE Bellows Help |

|---|---|

| Absorbs Movement | Compensates for axial, lateral, and angular motion. |

| Prevents Damage | Protects pipes and equipment from stress-induced cracks and leaks. |

| Chemical Resistance | Inert PTFE material withstands corrosive media. |

| Reduces Maintenance | Extends system lifespan by dampening vibrations and stress. |

Engineer unparalleled reliability into your piping systems with KINTEK PTFE components.

Our PTFE expansion bellows are precision-manufactured to solve your specific challenges, whether you're in the semiconductor, medical, laboratory, or industrial sector. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for absorbing thermal expansion, dampening vibrations, and resisting aggressive chemicals.

Contact KINTEK today to discuss your application and receive a custom solution that protects your critical infrastructure.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems