In short, yes. Expanded PTFE (ePTFE) gaskets are exceptionally easy to install. Their defining characteristics of softness and high compressibility allow them to be cut and shaped on-site with basic tools, conforming easily to a wide variety of flange surfaces without requiring excessive force.

The primary reason expanded PTFE gaskets are so simple to install is their remarkable ability to conform. Unlike rigid gaskets that demand perfect, clean flanges and high bolt loads, ePTFE's soft, malleable structure creates a reliable seal on irregular or even damaged surfaces with minimal installation effort.

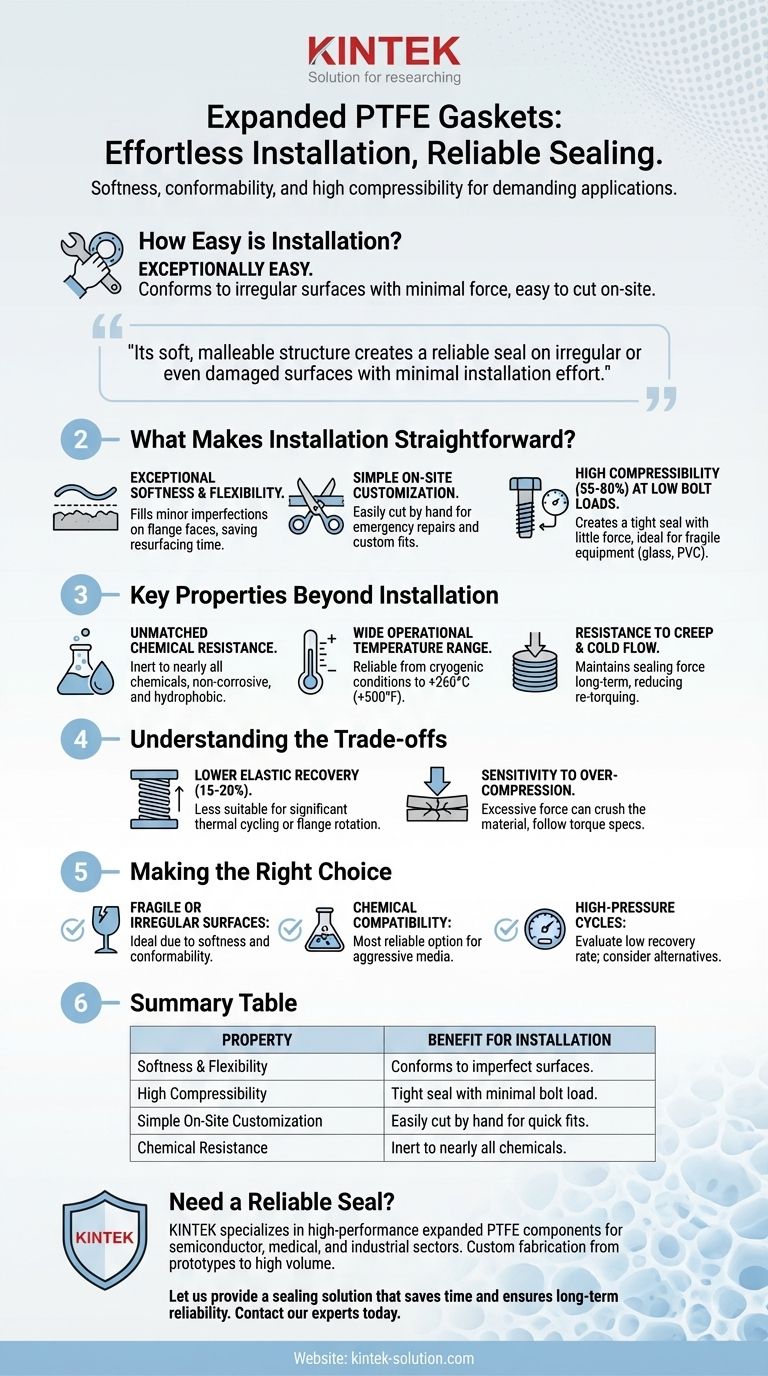

What Makes Expanded PTFE Installation So Straightforward?

The ease of use for ePTFE isn't a single feature but a result of several key material properties working in concert.

Exceptional Softness and Flexibility

Expanded PTFE is a very soft material. This allows it to easily fill in minor imperfections, scratches, and distortions on a flange face, which are common in real-world industrial settings.

This flexibility ensures an effective seal without needing to resurface the equipment, saving significant time and labor during installation or maintenance.

Simple On-Site Customization

Unlike many gasket materials that must be pre-cut to exact specifications, ePTFE can be easily cut by hand or with a simple machine.

This makes it ideal for emergency repairs or for custom-fitting gaskets to non-standard equipment, eliminating the need for precise templates and long lead times.

High Compressibility at Low Bolt Loads

Expanded PTFE has a very high compression ratio, typically between 55% and 80%. This means it can create a tight seal with very little clamping force.

This characteristic is critical when working with fragile equipment, such as glass-lined vessels, PVC piping, or plastic flanges, where excessive bolt torque would cause cracking or damage.

Key Properties Beyond Installation

While easy installation is a major benefit, the underlying properties of ePTFE are what make it a reliable choice for demanding applications.

Unmatched Chemical Resistance

As a synthetic fluoropolymer, ePTFE consists entirely of carbon and fluorine. This stable molecular structure makes it inert to nearly all industrial chemicals.

It is also non-corrosive, non-contaminating, and hydrophobic (water-repelling), making it suitable for high-purity, food-grade, or aggressive chemical services.

Wide Operational Temperature Range

Expanded PTFE performs reliably across an extremely broad temperature spectrum, from cryogenic conditions up to +260°C (+500°F).

This versatility allows it to be specified for a vast range of processes without concern for material degradation due to thermal exposure.

Resistance to Creep and Cold Flow

A significant advantage of expanded PTFE over standard PTFE is its resistance to creep and cold flow.

This means that once compressed, the gasket maintains its sealing force over long periods, reducing the need for re-torquing bolts and ensuring a durable, long-lasting seal.

Understanding the Trade-offs

No material is perfect for every situation. To make an informed decision, it's crucial to understand the limitations of expanded PTFE.

Lower Elastic Recovery

Expanded PTFE has a relatively low elastic recovery rate, typically 15% to 20%.

Once compressed, it does not "spring back" as much as some elastomeric or fiber gaskets. This means it may be less suitable for joints that experience significant thermal cycling or flange rotation, as it may not adapt as well to the changing gap.

Sensitivity to Over-Compression

While it excels at low bolt loads, excessive compression can crush the material's unique internal structure, diminishing its sealing capabilities and long-term stability.

Following the manufacturer's torque specifications is essential to avoid destroying the gasket's effectiveness during installation.

Making the Right Choice for Your Application

Use these guidelines to determine if expanded PTFE is the optimal choice for your specific goal.

- If your primary focus is sealing fragile or irregular surfaces: Expanded PTFE is an ideal choice due to its softness and ability to conform with minimal bolt load.

- If your primary focus is chemical compatibility: The inert nature of ePTFE makes it one of the most reliable options for aggressive or high-purity media.

- If your primary focus is a system with high-pressure cycles or flange movement: Carefully evaluate the low recovery rate; a gasket with higher spring-back, like a spiral wound gasket, may be more appropriate.

Ultimately, understanding both the strengths and limitations of expanded PTFE empowers you to select the right material for a reliable, long-lasting seal.

Summary Table:

| Property | Benefit for Installation |

|---|---|

| Softness & Flexibility | Conforms to imperfect or damaged flange surfaces. |

| High Compressibility | Creates a tight seal with minimal bolt load, protecting fragile equipment. |

| Simple On-Site Customization | Can be easily cut by hand for quick, custom fits. |

| Chemical Resistance | Inert to nearly all industrial chemicals, ensuring reliability. |

Need a reliable, easy-to-install seal for your application?

At KINTEK, we specialize in manufacturing high-performance expanded PTFE components, including gaskets, seals, and liners. Our precision-engineered PTFE products are ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the perfect seal for your specific needs—whether you're working with fragile glass-lined reactors, aggressive chemicals, or irregular flange surfaces.

Let us provide you with a sealing solution that saves time and ensures long-term reliability. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some real-world applications of PTFE coatings? Solve Friction, Corrosion & Contamination

- What advantages do PTFE bars offer in chemical industries? Ensure Safety and Efficiency in Demanding Applications

- What are the main challenges when machining Teflon (PTFE)? Overcome Softness, Heat, and Precision Issues

- How does the heat resistance of Teflon sheets benefit industrial applications? Unlock Performance Under Thermal Stress

- In what types of air compressors are PTFE oil scraper rings commonly used? A Guide to High-Performance Sealing

- What temperature range can welded PTFE bellow seals withstand? Unmatched Performance from -200°C to +260°C

- How can dimensional stability be maintained in machined PTFE parts? Master Precision Machining & Stress Relief

- What are the general properties and applications of Teflon industrial coatings? Solve Complex Engineering Challenges