In the chemical industry, PTFE (Polytetrafluoroethylene) bars are the material of choice for critical components due to their unparalleled chemical inertness, exceptional thermal stability, and unique low-friction surface. These properties combine to deliver significant advantages in safety, operational efficiency, and long-term cost-effectiveness when handling aggressive or high-purity substances.

The core advantage of PTFE is not just one property, but its rare combination of near-total chemical immunity and robust physical performance across a vast temperature range. This makes it a uniquely reliable material for applications where component failure would be catastrophic.

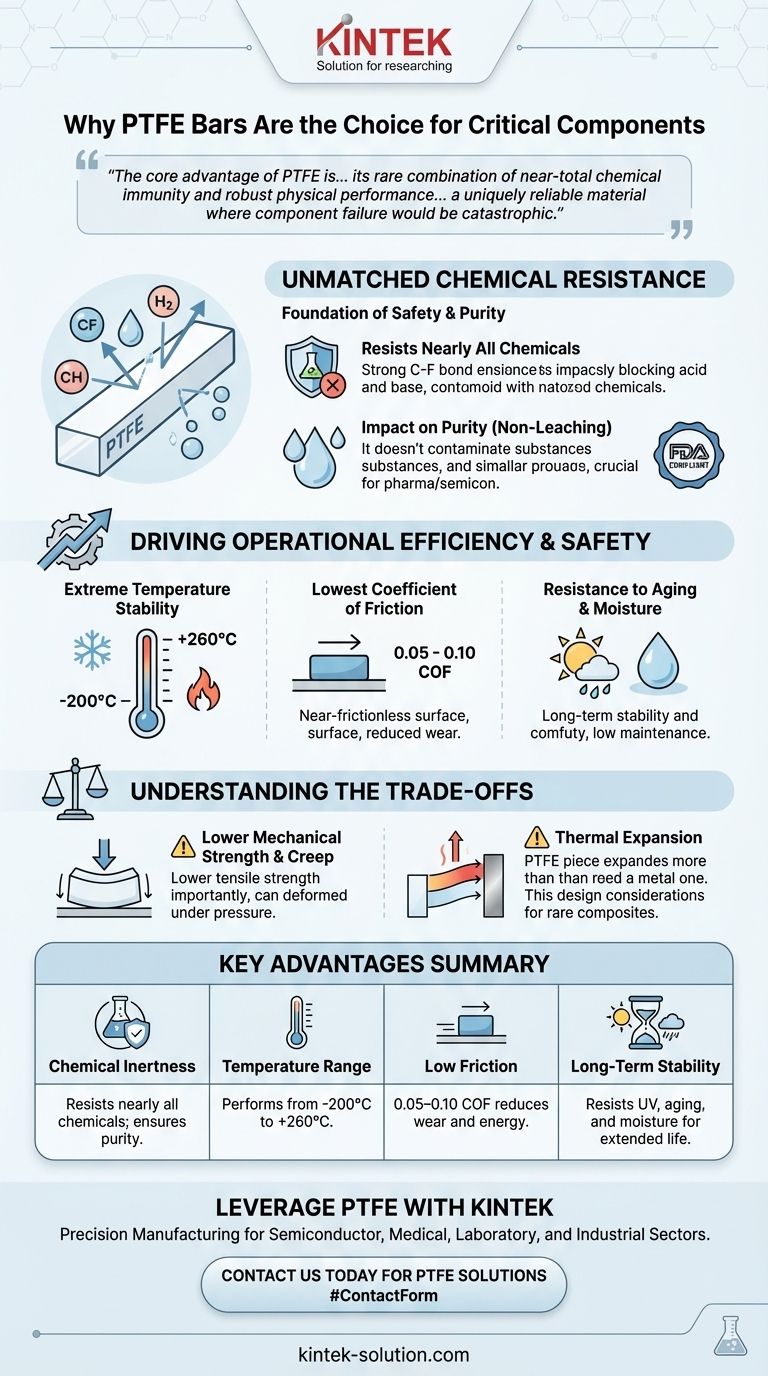

The Foundation: Unmatched Chemical Resistance

The primary reason PTFE is ubiquitous in chemical processing is its ability to withstand nearly any chemical it contacts. This property is fundamental to both safety and product purity.

Why PTFE Resists Corrosion

PTFE's resilience stems from the incredibly strong bonds between its carbon and fluorine atoms. This molecular structure is exceptionally stable and non-reactive.

This means PTFE bars can be used to fabricate components like seals, gaskets, and linings that are directly exposed to highly corrosive acids, solvents, and bases without degrading.

The Impact on Purity

Because PTFE is so inert, it does not leach contaminants into the substances it touches. This is critical in applications requiring high purity, such as in the pharmaceutical or semiconductor industries.

Furthermore, many grades of PTFE are FDA-compliant, making it one of the few high-performance plastics suitable for food-grade or sanitary applications within a chemical processing environment.

Driving Operational Efficiency and Safety

Beyond chemical resistance, PTFE's physical properties directly contribute to smoother, safer, and more efficient plant operations by minimizing maintenance and preventing failure.

Extreme Temperature Stability

PTFE maintains its integrity across an exceptionally wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to perform reliably in processes involving cryogenic fluids or high-temperature reactions without becoming brittle or deforming, a common failure point for lesser materials.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often cited between 0.05 and 0.10.

In practical terms, this creates a near-frictionless, non-stick surface. For components like valve seats, seals, and bearings, this means reduced wear, lower energy consumption, and prevention of the "stick-slip" phenomenon that can cause jerky movements and premature failure.

Resistance to Aging and Moisture

Unlike many other plastics and elastomers, PTFE does not degrade or become brittle with exposure to UV light or weather. It is also hydrophobic, meaning it repels water.

This long-term stability reduces the need for frequent component replacement, leading to less downtime and lower maintenance costs over the asset's lifecycle.

Understanding the Trade-offs

While its benefits are immense, PTFE is not the solution for every problem. An objective assessment requires acknowledging its limitations.

Lower Mechanical Strength

Compared to metals and engineering plastics like PEEK, PTFE is a relatively soft material. It has lower tensile strength and is more susceptible to creep (the tendency to deform slowly under constant stress).

This must be a key consideration in design, especially for high-pressure or high-load structural applications.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. When designing composite parts (e.g., a PTFE seal in a steel housing), this difference must be accounted for to prevent failure during temperature fluctuations.

Higher Initial Cost

The initial procurement cost of PTFE stock is typically higher than that of common plastics or some metals. However, this is often offset by its superior performance-to-price ratio and a lower total cost of ownership due to reduced maintenance and extended service life.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision based on the specific demands of the environment.

- If your primary focus is maximum safety and product purity: PTFE's chemical inertness and FDA-compliant grades make it the definitive choice for handling aggressive or sensitive fluids.

- If your primary focus is reducing maintenance and downtime: The non-stick surface and resistance to aging minimize cleaning cycles and the need for frequent component replacement.

- If your primary focus is performance in dynamic systems: PTFE's ultra-low friction coefficient is ideal for seals, bearings, and slide plates where minimizing wear and energy loss is critical.

Ultimately, choosing PTFE is an investment in operational certainty and long-term reliability for your most demanding chemical applications.

Summary Table:

| Key Advantage | Impact in Chemical Industries |

|---|---|

| Chemical Inertness | Resists nearly all acids, solvents, and bases; ensures product purity and safety. |

| Temperature Range | Performs reliably from -200°C to +260°C, suitable for cryogenic to high-heat processes. |

| Low Friction | Coefficient of 0.05–0.10 reduces wear, energy use, and maintenance in dynamic parts. |

| Long-Term Stability | Resists UV, aging, and moisture for extended service life and lower total cost of ownership. |

Ready to leverage PTFE's superior properties in your chemical applications?

At KINTEK, we specialize in precision manufacturing of PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the highest standards for chemical resistance, purity, and durability, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your operational safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components