At its core, the heat resistance of Teflon is not a standalone feature but a critical enabler. This property allows Polytetrafluoroethylene (PTFE) sheets to maintain their exceptional chemical inertness, mechanical strength, and non-stick surface at continuous operating temperatures up to 500°F (260°C). This unique combination makes Teflon indispensable for industrial applications where performance and reliability under intense thermal stress are non-negotiable.

Teflon's true value in industry isn't just its ability to endure heat; it's the fact that heat doesn't compromise its other elite properties. This unique stability—maintaining chemical resistance and a non-stick surface at high temperatures—is what solves critical engineering challenges.

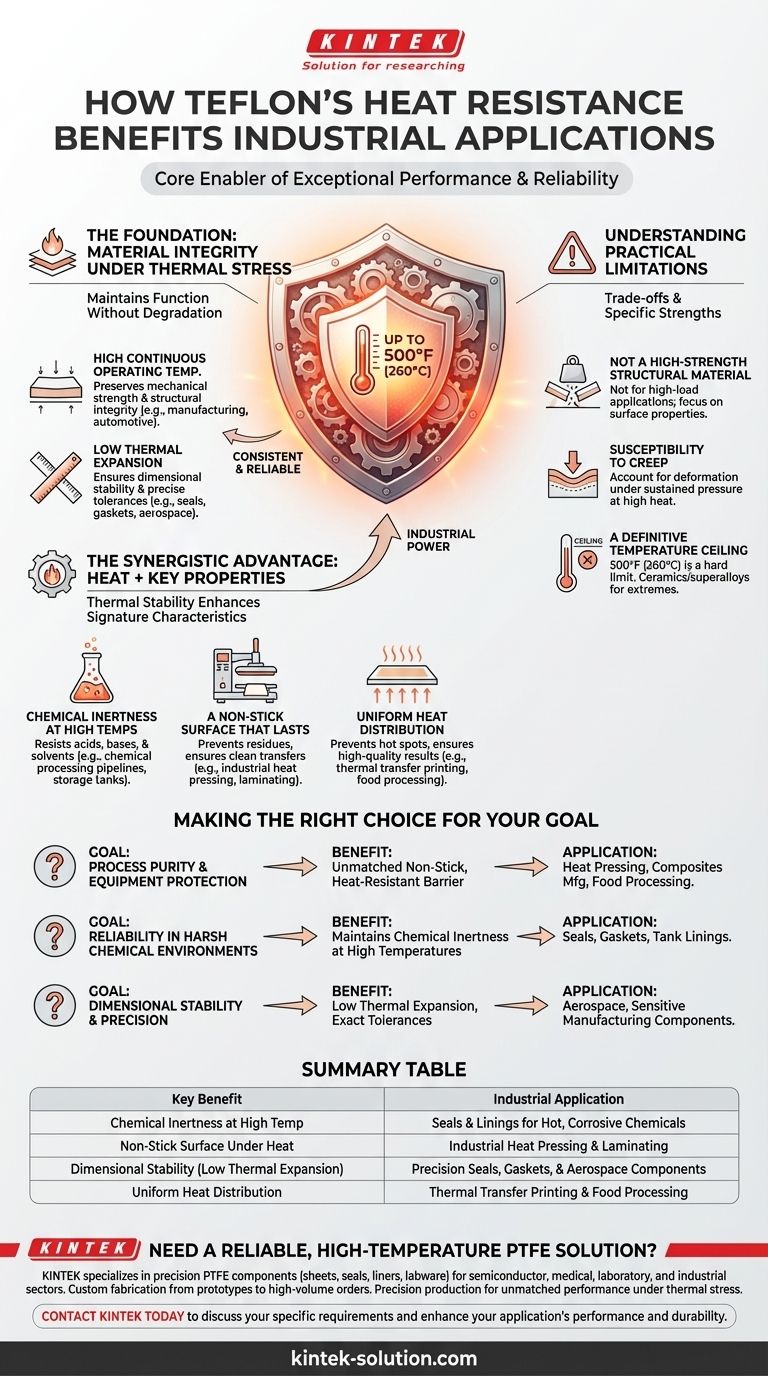

The Foundation: Material Integrity Under Thermal Stress

The primary benefit of Teflon's heat resistance is its ability to perform its function without degrading. While other materials may soften, melt, or become brittle when heated, Teflon remains consistent and reliable.

High Continuous Operating Temperature

Teflon sheets can operate continuously at 500°F (260°C) without losing their fundamental properties. This preserves the mechanical strength and structural integrity required for components in demanding environments like manufacturing and automotive systems.

Low Thermal Expansion

A critical, often overlooked, benefit is Teflon's dimensional stability. It has a very low coefficient of thermal expansion, meaning it does not significantly change in size or shape when heated or cooled. This is vital for precision applications like seals, gaskets, and aerospace components where exact tolerances must be maintained.

The Synergistic Advantage: Heat Resistance Plus Key Properties

Teflon's heat resistance rarely works in isolation. Its true industrial power comes from how this thermal stability enhances its other signature characteristics.

Chemical Inertness at High Temperatures

Many materials lose their resistance to corrosion as temperatures rise. Teflon, however, remains almost completely inert to acids, bases, and solvents even at elevated temperatures. This makes it the default choice for seals and linings in chemical processing pipelines and storage tanks where hot, corrosive substances are handled.

A Non-Stick Surface That Lasts

In applications like industrial heat pressing, Teflon’s non-stick quality is paramount. Its heat resistance ensures this surface remains effective, preventing inks, adhesives, and other residues from sticking to and damaging equipment. This results in clean transfers, flawless prints, and protection for delicate materials from scorching.

Uniform Heat Distribution

Teflon sheets also facilitate even heat distribution across a surface. In processes like thermal transfer printing, this consistency prevents hot spots and ensures a uniform, high-quality result across the entire product.

Understanding the Practical Limitations

To leverage Teflon effectively, it is crucial to understand its trade-offs. Its strengths are highly specific, and it is not a universal solution for all high-temperature challenges.

Not a High-Strength Structural Material

While mechanically stable, Teflon is not intended for high-load structural applications like steel or other alloys. Its value lies in its surface properties and stability, not its ability to bear significant physical weight or force.

Susceptibility to Creep

Under sustained pressure, especially at higher temperatures, PTFE can be subject to "creep," or slow deformation over time. This must be accounted for in the design of components like seals and gaskets that are under constant compression.

A Definitive Temperature Ceiling

The 500°F (260°C) limit is a hard ceiling. For applications involving extreme temperatures far beyond this, such as jet engine components or furnaces, engineers must turn to materials like ceramics or superalloys.

Making the Right Choice for Your Goal

To leverage Teflon's properties effectively, align your selection with your primary engineering challenge.

- If your primary focus is process purity and equipment protection: Teflon provides an unmatched non-stick, heat-resistant barrier in applications like heat pressing, composites manufacturing, and food processing.

- If your primary focus is reliability in harsh chemical environments: Its ability to maintain chemical inertness at high temperatures makes it the definitive choice for seals, gaskets, and tank linings.

- If your primary focus is dimensional stability and precision: Teflon's low thermal expansion ensures components hold their exact shape and tolerances during temperature fluctuations, which is critical for aerospace and sensitive manufacturing.

Ultimately, selecting Teflon is a decision to prioritize operational stability where heat, chemicals, and surface interaction converge.

Summary Table:

| Key Benefit | Industrial Application |

|---|---|

| Chemical Inertness at High Temp | Seals & Linings for Hot, Corrosive Chemicals |

| Non-Stick Surface Under Heat | Industrial Heat Pressing & Laminating |

| Dimensional Stability (Low Thermal Expansion) | Precision Seals, Gaskets, & Aerospace Components |

| Uniform Heat Distribution | Thermal Transfer Printing & Food Processing |

Need a Reliable, High-Temperature PTFE Solution?

Teflon's unique properties solve critical challenges in demanding environments. At KINTEK, we specialize in manufacturing precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components deliver unmatched performance and reliability under thermal stress.

Contact KINTEK today to discuss your specific requirements and let our expertise enhance your application's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments