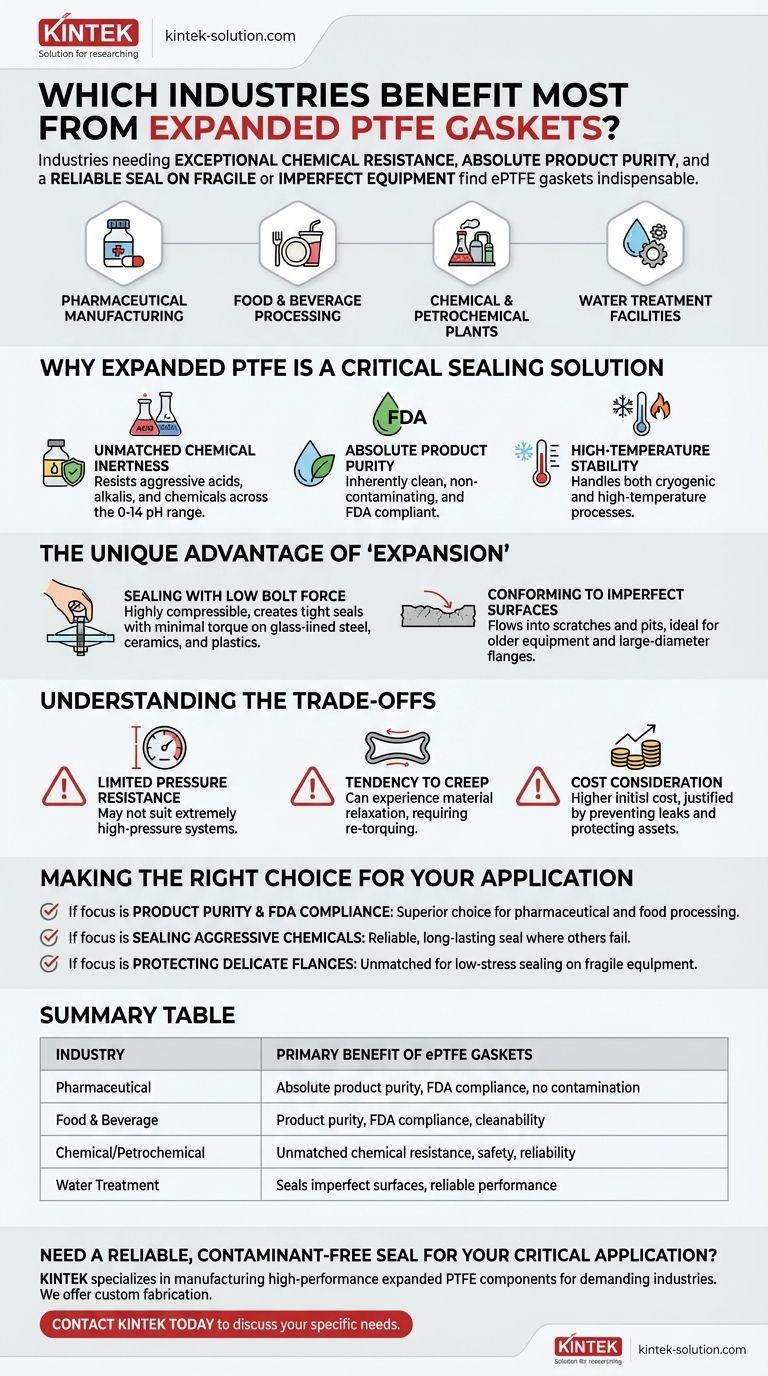

The industries that benefit most from expanded PTFE gaskets are those that require exceptional chemical resistance, absolute product purity, and a reliable seal on fragile or imperfect equipment. This makes them indispensable in pharmaceutical manufacturing, food and beverage processing, chemical and petrochemical plants, and water treatment facilities.

Expanded PTFE's unique value comes from combining the chemical inertness of standard PTFE with a soft, conformable structure. This allows it to create a tight, contaminant-free seal on delicate flanges where harder gaskets would fail or require excessive, damaging bolt force.

Why Expanded PTFE Is a Critical Sealing Solution

The benefits of expanded Polytetrafluoroethylene (ePTFE) stem from its core material properties, which solve persistent challenges in demanding industrial environments.

Unmatched Chemical Inertness

Expanded PTFE is chemically inert across the entire 0-14 pH range. It can withstand the most aggressive acids, alkalis, solvents, and chemicals without degrading.

This property makes it a default choice in chemical processing and petrochemical industries, where leakage of corrosive media can lead to catastrophic equipment failure and safety hazards.

Absolute Product Purity

The material is inherently clean, does not contaminate the media it contacts, and meets stringent FDA requirements for food and drug contact.

This is non-negotiable for the pharmaceutical and food and beverage industries. Using ePTFE gaskets ensures that the final product remains pure and free from leachables or contaminants from the sealing material itself.

High-Temperature Stability

Expanded PTFE maintains its integrity and sealing capability over a broad temperature range, handling both cryogenic conditions and high-temperature processes common in many manufacturing sectors.

The Unique Advantage of "Expansion"

The "expansion" process creates a multidirectional fibrous structure that gives ePTFE gaskets physical properties far superior to standard, rigid PTFE sheets for certain applications.

Sealing with Low Bolt Force

Expanded PTFE is highly compressible and soft, allowing it to conform and create a tight seal with minimal bolt torque.

This is critical for protecting fragile or stress-sensitive flange materials like glass-lined steel, ceramics, and plastics, which are common in specialty chemical and pharmaceutical plants. Over-tightening a standard gasket on these flanges can easily cause them to crack.

Conforming to Imperfect Surfaces

The soft, fibrous nature of ePTFE allows it to flow into and fill small imperfections like scratches, pits, and warps on a flange face.

This makes it an ideal problem-solver for older equipment, large-diameter flanges in water treatment plants, and non-critical utility piping like HVAC systems, where flange surfaces may be worn or slightly misaligned.

Understanding the Trade-offs

While highly effective, expanded PTFE is not a universal solution. Understanding its limitations is key to proper application.

Limited Pressure Resistance

While excellent for many applications, solid ePTFE gaskets may not be suitable for extremely high-pressure systems where a metallic or spiral-wound gasket would be required for structural integrity.

Tendency to Creep

The same softness that allows ePTFE to seal effectively can also lead to "creep," or material relaxation, over time, especially after a thermal cycle. This may require re-torquing the flange bolts to maintain the seal.

Cost Consideration

Expanded PTFE is a high-performance material and can be more expensive than common gasketing materials like compressed fiber or rubber. However, its cost is often justified by preventing leaks of valuable or hazardous products.

Making the Right Choice for Your Application

Selecting the right gasket depends entirely on the primary challenge you need to solve.

- If your primary focus is product purity and FDA compliance: Expanded PTFE is the superior choice for pharmaceutical and food processing lines to prevent any contamination.

- If your primary focus is sealing aggressive or high-purity chemicals: The near-universal chemical inertness of ePTFE provides a reliable, long-lasting seal where other materials would quickly fail.

- If your primary focus is protecting delicate or irregular flanges: The low-stress sealing capability of expanded PTFE is unmatched for glass-lined steel, plastic, or older, worn equipment.

By understanding these properties, you can confidently specify expanded PTFE for critical applications where other materials would compromise safety, purity, or equipment integrity.

Summary Table:

| Industry | Primary Benefit of ePTFE Gaskets |

|---|---|

| Pharmaceutical | Absolute product purity, FDA compliance, no contamination |

| Food & Beverage | Product purity, FDA compliance, cleanability |

| Chemical/Petrochemical | Unmatched chemical resistance, safety, reliability |

| Water Treatment | Seals imperfect surfaces, reliable performance |

Need a reliable, contaminant-free seal for your critical application?

KINTEK specializes in manufacturing high-performance expanded PTFE components, including gaskets, seals, and liners. Our expertise ensures precision and purity for the most demanding industries, including semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact sealing solution your process requires.

Contact KINTEK today to discuss your specific needs and protect your process with confidence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does temperature affect PTFE slide bearing performance? Ensure Reliability Under High Heat

- How is the body portion of a PTFE seal element typically constructed? Securing Performance with Clamped Design

- What is the alternative to PTFE gaskets that combines its advantages with better sealing properties? Discover Enhanced Sealing Solutions

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the overall benefits of using PTFE in lubrication systems? Achieve Unmatched Reliability in Extreme Conditions

- How is Teflon used in the aerospace industry? Essential for Seals, Coatings & Insulation

- When are split PTFE backup rings particularly suitable? Ideal for Retrofitting and High-Pressure Seals

- Why is PTFE used in electrical applications? Unmatched Insulation for High-Performance Components