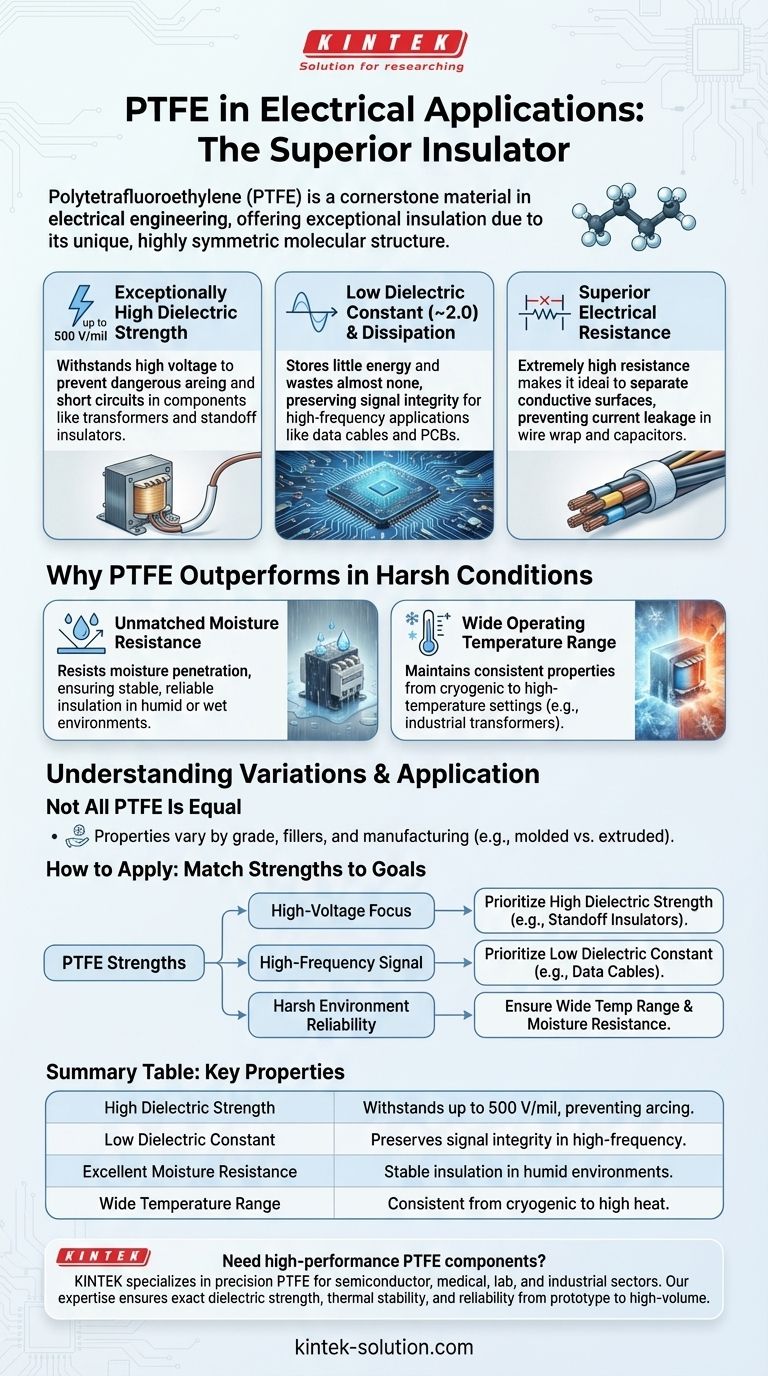

Polytetrafluoroethylene (PTFE) is a cornerstone material in electrical and electronic engineering because of its exceptional capabilities as an electrical insulator. Its unique, highly symmetric molecular structure results in a combination of high dielectric strength, a low dielectric constant, and outstanding resistance to environmental factors like moisture and heat, ensuring reliable and safe performance in the most demanding applications.

PTFE's value extends beyond simple insulation; its molecular stability ensures that its electrical properties remain consistent across a wide range of temperatures, frequencies, and environmental conditions, making it a uniquely durable choice for critical components.

The Fundamental Electrical Properties of PTFE

The electrical superiority of PTFE is not due to a single characteristic but a combination of three core properties that make it an almost ideal insulator.

Exceptionally High Dielectric Strength

Dielectric strength measures a material's ability to withstand a high voltage before it breaks down and allows current to pass through.

PTFE is one of the best insulators known, capable of withstanding up to 500 volts per mil of thickness. This makes it ideal for high-voltage environments, where it is used to prevent dangerous arcing and short circuits in components like transformers and standoff insulators.

Low Dielectric Constant & Dissipation Factor

The dielectric constant indicates how much electrical energy a material can store, while the dissipation factor measures how much of that energy is lost as heat.

PTFE has a very low dielectric constant (around 2.0) and a low dissipation factor. This means it stores very little energy and wastes almost none, preserving the integrity of electrical signals, which is critical for high-frequency applications like data cables and printed circuit boards.

Superior Electrical Resistance

Electrical resistance is the fundamental measure of how strongly a material opposes the flow of electric current.

PTFE possesses extremely high electrical resistance, making it a near-perfect material to separate conductive surfaces. This property is essential for components like wire wrap, cable insulation, and capacitors, where preventing current leakage is the primary goal.

Why PTFE Outperforms Other Insulators in Harsh Conditions

Many materials can insulate, but few can maintain their performance when faced with real-world challenges like temperature swings and moisture.

Unmatched Moisture Resistance

Many plastics, like nylon or PVC, can absorb moisture from the air, which degrades their insulating properties over time.

PTFE is fundamentally different, as it resists moisture penetration almost completely. This ensures its insulating qualities remain stable and reliable even in humid or wet environments.

Wide Operating Temperature Range

PTFE is renowned for its thermal stability, maintaining its structure and properties across an incredibly broad temperature spectrum.

This means its excellent electrical characteristics are consistent whether used in cryogenic applications or in high-temperature components like industrial transformers, providing predictable performance where other materials would fail.

Understanding the Trade-offs and Variations

While PTFE is a superior material, it's critical to understand that not all PTFE is identical. Its final properties are heavily influenced by its production.

Not All PTFE is Created Equal

The electrical properties of a PTFE component can vary based on its grade, the type and concentration of any fillers, and the manufacturing process.

For example, a molded sheet may have different electrical test results than a thin-walled extruded tube. Additives used to enhance mechanical properties can sometimes alter the electrical characteristics.

The Importance of Specification and Testing

Because of these potential variations, relying on generic datasheets is not enough for critical applications.

Ensuring the specific material you are using has been tested and certified to meet your application's requirements is crucial. This guarantees the end product will perform safely and reliably as designed.

How to Apply This to Your Project

To select the right PTFE, align its specific strengths with your primary engineering goal.

- If your primary focus is high-voltage insulation: Look for PTFE grades with a certified high dielectric strength, often used in standoff insulators and encapsulation devices.

- If your primary focus is high-frequency signal integrity: Prioritize PTFE with a documented low dielectric constant and dissipation factor, essential for data cables and advanced circuit boards.

- If your primary focus is reliability in harsh environments: Ensure the chosen PTFE maintains its properties across your required temperature range and offers superior moisture resistance.

By understanding these core electrical advantages, you can confidently specify PTFE to ensure the safety, performance, and longevity of your critical components.

Summary Table:

| Key Property | Why It Matters for Electrical Applications |

|---|---|

| High Dielectric Strength | Withstands up to 500 V/mil, preventing arcing in high-voltage components like transformers. |

| Low Dielectric Constant (~2.0) | Preserves signal integrity in high-frequency applications like data cables and PCBs. |

| Excellent Moisture Resistance | Maintains stable insulation properties even in humid or wet environments. |

| Wide Temperature Range | Performs consistently from cryogenic to high-temperature settings. |

Need high-performance PTFE components for your critical electrical applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures that your PTFE parts deliver the exact dielectric strength, thermal stability, and reliability your project demands, from prototype to high-volume production.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers