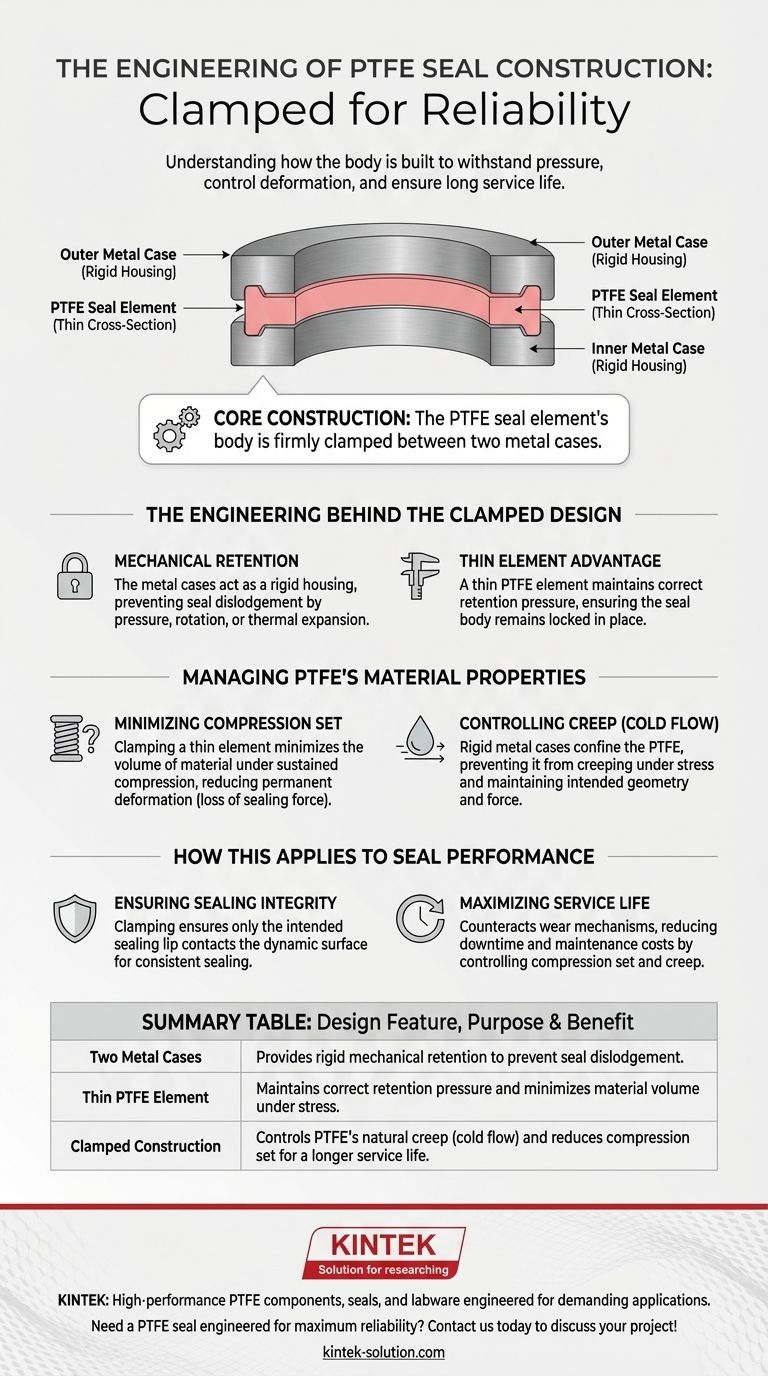

At its core, a PTFE seal element is constructed with its body firmly clamped between two metal cases. This design is not arbitrary; it's a precise engineering solution to secure the PTFE element, which is the heart of the seal, while managing the material's unique properties to ensure a long and reliable service life.

The fundamental challenge in PTFE seal design is to mechanically secure the seal element while controlling its natural tendency to deform under pressure and temperature. The dual-case clamping method is the standard solution to this problem.

The Engineering Behind the Clamped Design

The effectiveness of a PTFE seal hinges on how well its body is held in place. The clamped construction directly addresses the mechanical and material challenges inherent in creating a durable, leak-free seal.

The Role of the Metal Cases

The two metal cases act as a rigid housing for the flexible PTFE element. This structure serves a critical function: mechanical retention.

Without this clamping force, the seal element could easily be dislodged by pressure, shaft rotation, or thermal expansion, leading to catastrophic failure.

Why a Thin Element is Critical

The design specifies a thin PTFE element for very specific reasons related to the material's behavior under stress.

Using a thin cross-section helps maintain the correct retention pressure against the housing. This ensures the seal body remains locked in place throughout its operational life.

Understanding the Trade-offs: Managing PTFE's Properties

Polytetrafluoroethylene (PTFE) is an excellent material for seals due to its low friction and chemical inertness. However, it presents two key challenges that the clamped design mitigates: compression set and creep.

Minimizing Compression Set

Compression set is the permanent deformation a material undergoes after being compressed for a period. A seal that takes a permanent "set" will lose its ability to exert pressure against the shaft, leading to leaks.

By clamping a thin element, the design minimizes the volume of material under sustained compression, which in turn reduces the potential for permanent deformation.

Controlling Creep (Cold Flow)

Creep, or cold flow, is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. PTFE is particularly susceptible to creep.

The rigid metal cases confine the PTFE, preventing it from creeping out of position. This ensures the seal maintains its intended geometry and sealing force over time.

How This Applies to Seal Performance

This construction method directly translates to a more reliable and long-lasting seal. The design is a carefully balanced system where each component plays a role in achieving a specific engineering outcome.

Ensuring Sealing Integrity

By firmly clamping the body, the design ensures that only the intended sealing lip is in contact with the dynamic surface (the shaft). This maintains a consistent and predictable sealing point.

Maximizing Service Life

The entire construction is engineered to counteract the natural wear-and-tear mechanisms of the PTFE material. By controlling for compression set and creep, the seal can perform reliably for a much longer operational window.

This leads to reduced downtime, lower maintenance costs, and greater overall system reliability.

Key Design Principles for Your Application

Understanding this construction helps in selecting and specifying the right seal for your needs.

- If your primary focus is high-pressure sealing: The integrity of the clamp is paramount to prevent the seal element from being physically extruded by the pressure.

- If your primary focus is long-term reliability: A design that effectively minimizes creep and compression set will provide the most stable and predictable service life.

Ultimately, the clamped body construction is the foundational design that makes modern, high-performance PTFE seals possible.

Summary Table:

| Design Feature | Purpose & Benefit |

|---|---|

| Two Metal Cases | Provides rigid mechanical retention to prevent seal dislodgement. |

| Thin PTFE Element | Maintains correct retention pressure and minimizes material volume under stress. |

| Clamped Construction | Controls PTFE's natural creep (cold flow) and reduces compression set for a longer service life. |

Need a PTFE seal engineered for maximum reliability?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and labware. Our precision engineering ensures your seals are constructed to effectively manage material properties like creep and compression set, providing superior sealing integrity and longevity for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a custom prototype or a high-volume order, our team is ready to deliver a solution tailored to your specific pressure, temperature, and lifecycle requirements.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability