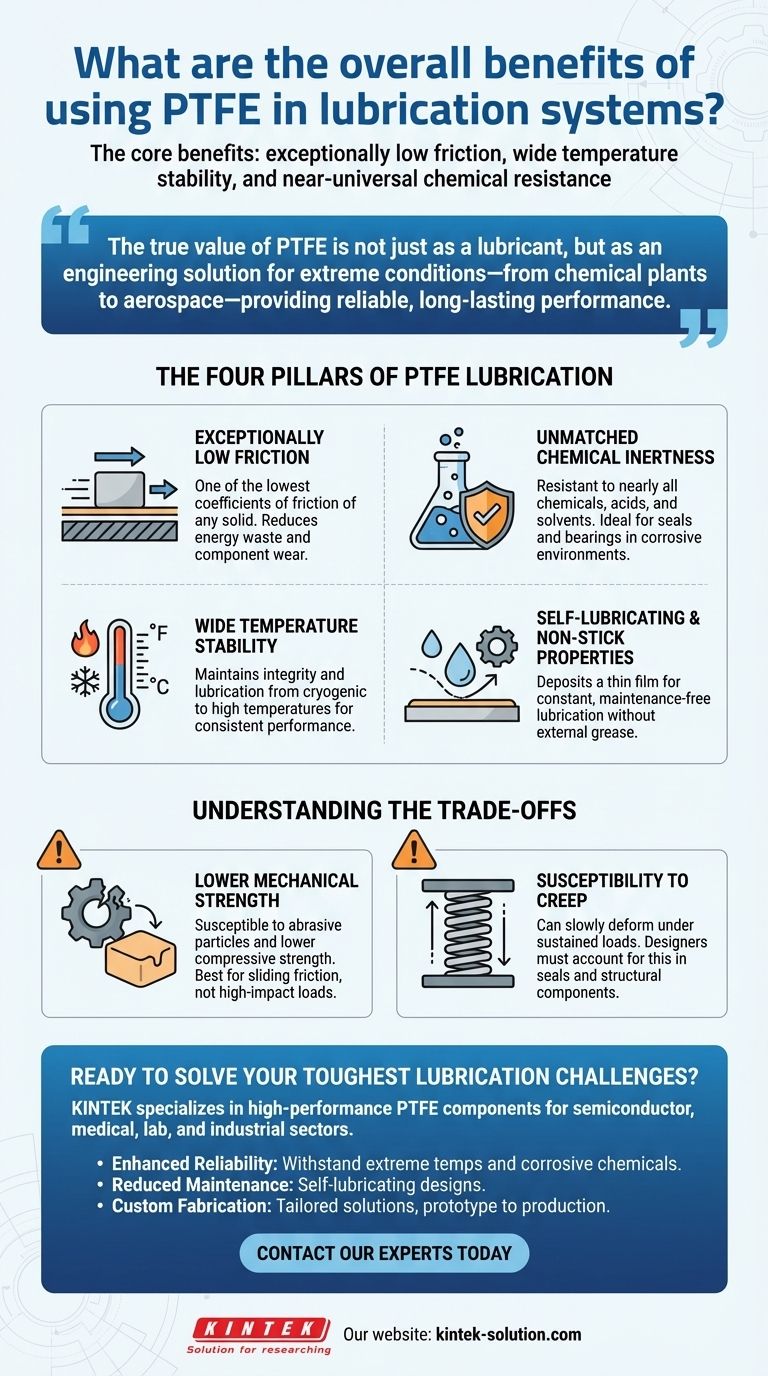

The core benefits of using PTFE in lubrication are its exceptionally low friction, wide temperature stability, and near-universal chemical resistance. This unique combination of properties reduces wear, enhances operational efficiency, and dramatically extends the lifespan of components, especially in demanding environments where conventional lubricants would fail.

The true value of Polytetrafluoroethylene (PTFE) is not just as a lubricant, but as an engineering solution. It excels in extreme conditions—from corrosive chemical plants to high-altitude aerospace systems—by providing reliable, long-lasting performance where other materials cannot.

The Four Pillars of PTFE Lubrication

To understand why PTFE is so effective, we must look at its fundamental material properties. These four characteristics work together to deliver superior performance.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This "slipperiness" directly translates to less resistance between moving parts.

This property means less energy is wasted as heat, reducing overall energy consumption and minimizing wear on critical components.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. It does not corrode or degrade when exposed to aggressive substances.

This makes it an ideal material for seals, gaskets, and bearings in chemical processing, where it ensures leak-proof operation and prevents system contamination.

Wide Temperature Stability

PTFE maintains its integrity and lubricating properties across an exceptionally broad temperature range. It remains effective in cryogenic conditions and at high temperatures where oil-based lubricants would break down.

This stability ensures consistent and reliable performance in environments with extreme thermal cycling, such as in automotive or aerospace applications.

Self-Lubricating and Non-Stick Properties

As a solid lubricant, PTFE deposits a thin, continuous film on moving surfaces, providing constant lubrication without the need for external grease or oil.

Its non-stick nature also prevents other materials from adhering to the surface, which is critical for smooth operation in machinery like slideways and guides.

Understanding the Trade-offs

While its advantages are significant, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It can be susceptible to damage from sharp, abrasive particles and has lower compressive strength.

This means it is best suited for applications focused on sliding friction rather than high-impact or heavy load-bearing scenarios without proper reinforcement.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time in a process known as "creep" or "cold flow."

System designers must account for this characteristic, especially when using PTFE for critical seals or structural components that will be under constant pressure.

Application Context is Key

The decision to use PTFE must be based on the specific operational challenges. It is a premium material engineered to solve problems of friction, corrosion, and temperature that commodity lubricants cannot handle.

Making the Right Choice for Your System

Selecting the right material comes down to your primary engineering goal.

- If your primary focus is reliability in extreme environments: PTFE's chemical inertness and thermal stability make it the definitive choice for systems exposed to corrosive materials or wide temperature swings.

- If your primary focus is reducing energy loss and wear: Its ultra-low coefficient of friction offers a direct path to more efficient machinery and a longer lifespan for moving parts.

- If your primary focus is long-term, low-maintenance operation: PTFE's self-lubricating properties provide a "fit-and-forget" solution that ensures consistent performance over time.

By understanding both its profound strengths and its specific limitations, you can leverage PTFE to build more efficient and resilient systems.

Summary Table:

| Key Benefit | Description | Primary Application Impact |

|---|---|---|

| Exceptionally Low Friction | One of the lowest coefficients of friction of any solid material. | Reduces energy consumption and minimizes component wear. |

| Unmatched Chemical Inertness | Resistant to nearly all industrial chemicals, acids, and solvents. | Ideal for seals and bearings in corrosive environments; prevents contamination. |

| Wide Temperature Stability | Maintains integrity from cryogenic to high temperatures. | Ensures reliable performance in applications with extreme thermal cycling. |

| Self-Lubricating & Non-Stick | Deposits a thin, continuous film without needing external grease. | Provides long-term, low-maintenance operation for moving parts. |

Ready to Solve Your Toughest Lubrication Challenges?

PTFE's unique properties make it the ideal engineering solution for systems where conventional lubricants fail. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you to deliver:

- Enhanced Reliability: Components that withstand extreme temperatures and corrosive chemicals.

- Reduced Maintenance: Self-lubricating designs for long-lasting, efficient operation.

- Custom Fabrication: Solutions tailored from prototype to high-volume production.

Let's engineer a more resilient system together. Contact our experts today to discuss your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability