At their core, Polytetrafluoroethylene (PTFE) stirrers are standard equipment in environments demanding extreme chemical resistance and purity. They are most frequently applied in the chemical processing, pharmaceutical, and bioprocessing industries for mixing substances inside glass or bio-reactors.

The decision to use a PTFE stirrer is driven by one fundamental need: to mix a solution without the stirrer itself reacting with, degrading, or contaminating the substance. Its unparalleled chemical inertness and wide temperature tolerance make it the default choice for aggressive and sensitive applications.

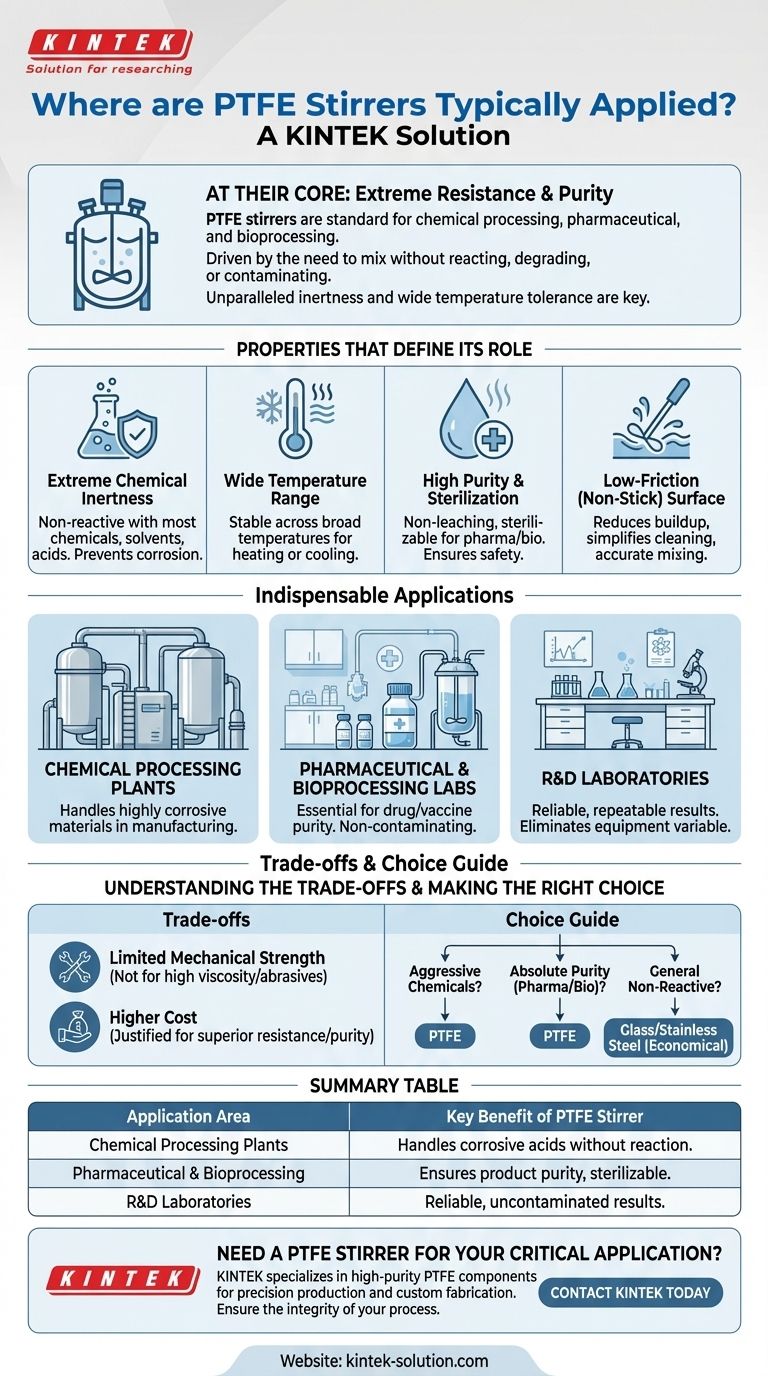

The Properties That Define Its Role

The widespread use of PTFE stirrers isn't accidental; it's a direct result of the material's unique combination of properties. Understanding these attributes is key to understanding its applications.

Extreme Chemical Inertness

PTFE is virtually non-reactive with almost all chemicals, solvents, and acids. This makes it an ideal material for use in chemical manufacturing and laboratory research where aggressive reagents are common. The stirrer will not corrode or break down, ensuring the integrity of the chemical process.

Wide Temperature Range

The material maintains its stability across a broad spectrum of temperatures. This allows PTFE stirrers to be used in reactions that require significant heating or cooling without risk of the material melting, warping, or becoming brittle.

High Purity and Sterilization

In pharmaceutical and bioprocessing, preventing contamination is the highest priority. PTFE is inherently pure and does not leach substances into a mixture. Crucially, it can be sterilized either chemically or thermally, a non-negotiable requirement for medical and biological applications.

Low-Friction (Non-Stick) Surface

The famous "non-stick" quality of PTFE is also beneficial in a stirring context. This low-friction surface can help reduce the buildup of viscous materials on the stirrer itself, simplifying the cleaning process and ensuring more accurate mixing.

Where PTFE Stirrers Are Indispensable

While the base material is used in everything from aerospace to cookware, PTFE stirrers are specifically found where liquid agitation meets stringent environmental demands.

Chemical Processing Plants

In large-scale industrial settings, PTFE stirrers are used in vessels and reactors for manufacturing chemicals. They safely handle highly corrosive materials that would quickly destroy stirrers made of metal or other plastics.

Pharmaceutical & Bioprocessing Labs

This is a primary application area. When producing medications, vaccines, or other sensitive biological compounds, the stirrer must not introduce any foreign material into the batch. PTFE's inertness and sterilizability are essential for maintaining product safety and efficacy.

Research and Development Laboratories

In any R&D lab, the goal is to get reliable, repeatable results. Using a PTFE stirrer eliminates a significant variable—the potential for the equipment to react with the experiment. This ensures that the observed results are due to the reagents, not an unexpected chemical reaction with the stirrer.

Understanding the Trade-offs

While highly effective, PTFE is not the universal solution for every stirring application. Its unique properties come with practical limitations that are important to recognize.

Limited Mechanical Strength

PTFE is a relatively soft material. It is not well-suited for applications involving high-viscosity liquids that require extreme torque or for mixing abrasive slurries that could wear down the material over time.

Higher Cost

Compared to common alternatives like glass or stainless steel, PTFE is a more expensive material. Its use is justified when its superior chemical resistance and purity are absolute requirements, not just preferences.

When to Consider Alternatives

For simple mixing of non-corrosive aqueous solutions, a glass or stainless steel stirrer is often a more practical and cost-effective choice. The decision always comes back to the specific chemical environment and purity demands of the task.

Making the Right Choice for Your Goal

Selecting the correct stirrer material is a critical decision based on your specific operational needs.

- If your primary focus is handling aggressive or corrosive chemicals: PTFE is the safest and most reliable choice due to its near-universal inertness.

- If your primary focus is ensuring absolute purity for pharma or bio-applications: PTFE is essential for its non-leaching properties and its ability to be reliably sterilized.

- If your primary focus is general-purpose mixing of non-reactive substances: A more economical material like glass or stainless steel may be perfectly sufficient for your needs.

Ultimately, choosing a PTFE stirrer is an investment in process safety, purity, and the integrity of your results.

Summary Table:

| Application Area | Key Benefit of PTFE Stirrer |

|---|---|

| Chemical Processing Plants | Handles highly corrosive acids and solvents without reacting or degrading. |

| Pharmaceutical & Bioprocessing | Ensures product purity, is non-leaching, and can be sterilized. |

| R&D Laboratories | Provides reliable, uncontaminated results by eliminating equipment as a variable. |

Need a PTFE Stirrer for Your Critical Application?

KINTEK specializes in manufacturing high-purity PTFE components, including stirrers, for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications for chemical resistance and sterility.

Contact KINTEB today to discuss your project requirements and ensure the integrity of your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the durability benefits of using PTFE/silicone septums in chromatography? Maximize Uptime & Data Integrity

- What are the advantages of using PTFE stirrers and shafts in corrosive applications? Ensure Purity and Reliability

- What are the best practices for using PTFE syringe filters? Achieve Pure, Reliable Filtration

- What are the typical applications of PTFE filters in scientific filtration? Master Harsh Chemical and Gas Filtration

- What makes PTFE filtration systems advantageous for industrial and scientific use? Unmatched Chemical & Thermal Stability

- What overall role do PTFE/silicone septa play in HPLC workflows? Protect Sample Integrity for Accurate Results

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity

- What are the advantages of the PTFE bottle's non-stick surface? Ensure Purity and Efficiency in Your Lab