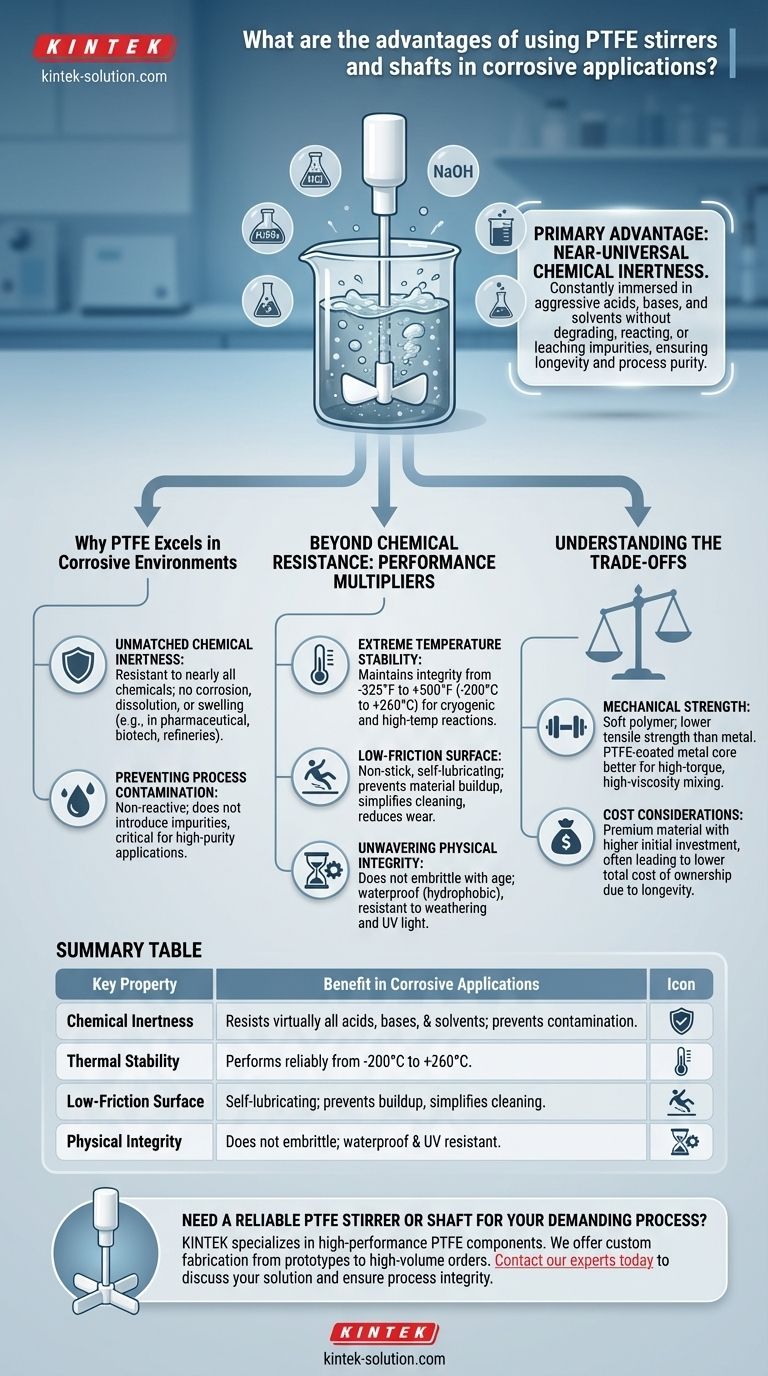

The primary advantage of using PTFE stirrers and shafts in corrosive applications is their near-universal chemical inertness. Polytetrafluoroethylene (PTFE) can be constantly immersed in the most aggressive acids, bases, and solvents without degrading, reacting, or leaching impurities into the mixture, ensuring both the longevity of the equipment and the purity of the process.

The true value of PTFE lies not in a single property, but in its unique combination of extreme chemical resistance, wide thermal stability, and an ultra-low-friction surface. This synergy makes it an indispensable material for maintaining process integrity in demanding chemical environments.

Why PTFE Excels in Corrosive Environments

At the core of PTFE's performance is its molecular structure. The strong carbon-fluorine bonds create an exceptionally stable and non-reactive material, leading to several key benefits.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, acids, and bases. This means it will not corrode, dissolve, or swell, even with prolonged exposure to harsh substances commonly found in pharmaceutical labs, biotech research, and industrial refineries.

Preventing Process Contamination

Because PTFE does not react with the substances it contacts, it does not introduce impurities. This is critical in high-purity applications where even trace amounts of contamination can ruin a batch or an experiment.

Beyond Chemical Resistance: The Performance Multipliers

While inertness is the main reason for choosing PTFE, its other physical properties work in concert to enhance its performance, reliability, and safety in the lab or plant.

Extreme Temperature Stability

PTFE maintains its integrity across an exceptionally broad temperature range, typically from -325°F to +500°F (-200°C to +260°C). This allows it to be used reliably in both cryogenic processes and high-temperature reactions without becoming brittle or melting.

The Impact of a Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick, self-lubricating quality prevents material from building up on the stirrer or shaft, which simplifies cleaning, reduces cross-contamination, and minimizes wear on the equipment.

Unwavering Physical Integrity

Unlike many other materials, PTFE does not embrittle or degrade with age. It is also completely waterproof (hydrophobic) and highly resistant to weathering and UV light, ensuring long-term, predictable performance.

Understanding the Trade-offs

While its benefits are significant, it's important to understand PTFE's limitations to ensure it is the right choice for a specific mechanical application.

Mechanical Strength

PTFE is a relatively soft polymer. While its low friction provides a form of wear resistance, it does not have the high tensile or structural strength of stainless steel or other metal alloys. For extremely high-viscosity mixing that requires immense torque, a PTFE-coated metal core is often a better solution than a solid PTFE shaft.

Cost Considerations

High-purity, virgin PTFE is a premium performance polymer. While its longevity and low maintenance often result in a lower total cost of ownership, the initial investment can be higher than for equipment made from glass or certain metals.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary goal.

- If your primary focus is analytical purity and preventing contamination: PTFE is the superior choice due to its inertness and non-leaching properties.

- If your primary focus is operating in extreme temperatures and with aggressive chemicals: PTFE's combined thermal stability and chemical resistance make it one of the few materials that can handle the job reliably.

- If your primary focus is high-torque mechanical mixing of non-corrosive media: A stainless steel stirrer may be a more cost-effective and structurally sound option.

Ultimately, PTFE provides an unparalleled combination of properties for ensuring reliability and purity in corrosive and demanding applications.

Summary Table:

| Key Property | Benefit in Corrosive Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents contamination. |

| Thermal Stability | Performs reliably from -200°C to +260°C (-325°F to +500°F). |

| Low-Friction Surface | Self-lubricating; prevents material buildup and simplifies cleaning. |

| Physical Integrity | Does not embrittle with age; waterproof and UV resistant for long life. |

Need a reliable PTFE stirrer or shaft for your demanding process?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including stirrers, shafts, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors where material purity and equipment longevity are critical.

We offer custom fabrication from prototypes to high-volume orders, ensuring your component meets the exact specifications required for your corrosive application.

Contact our experts today to discuss your custom PTFE solution and ensure the integrity of your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability