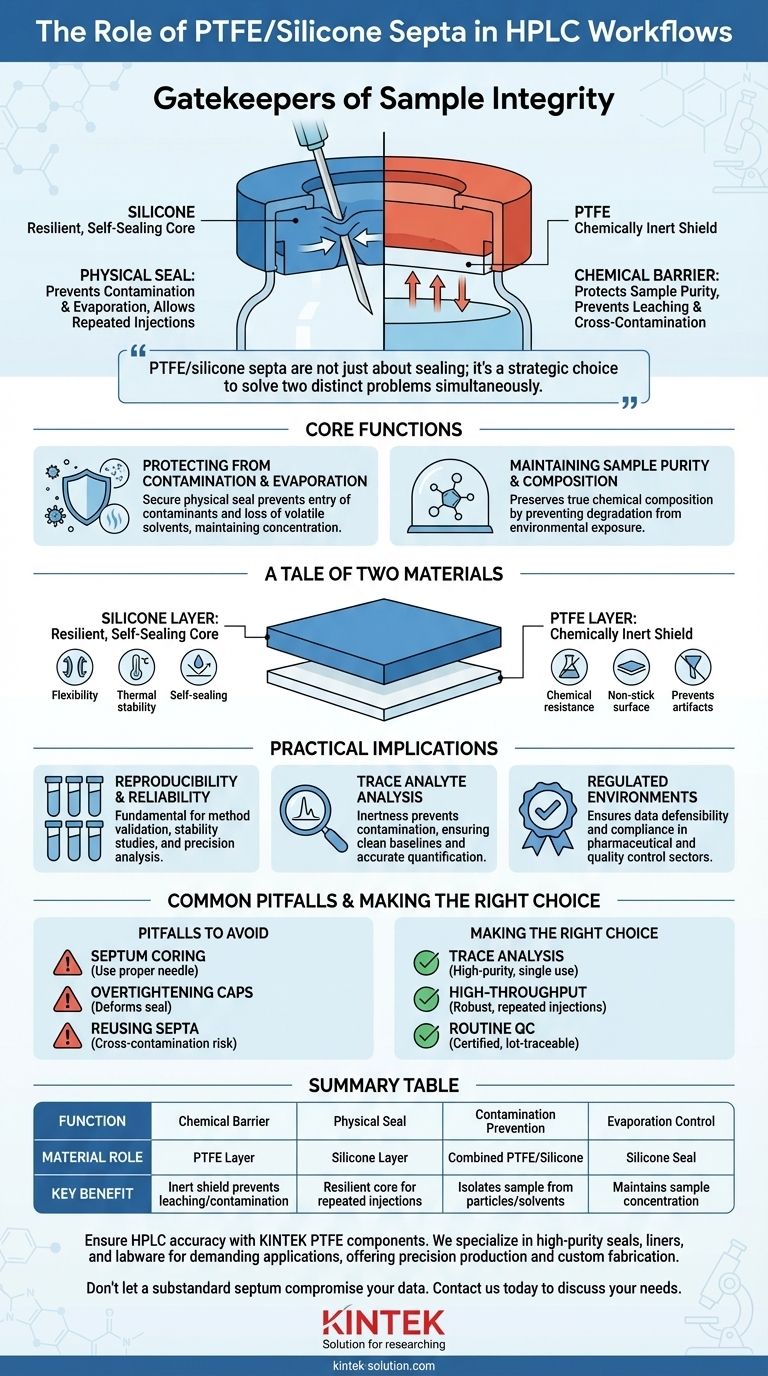

In short, PTFE/silicone septa act as the primary gatekeepers of sample integrity in HPLC workflows. They form a secure, two-part barrier inside an autosampler vial cap that protects the sample from contamination and evaporation while allowing for clean, repeated injections by the autosampler needle. This function is critical for ensuring the accuracy, reliability, and reproducibility of your analytical results.

The use of a PTFE/silicone septum is not merely about sealing a vial; it's a strategic choice to solve two distinct problems simultaneously. The PTFE layer provides an inert chemical shield against the sample, while the silicone layer provides the physical, resealable barrier necessary for automated analysis.

The Core Function: A Barrier Against Inaccuracy

The fundamental job of a septum is to isolate the sample inside the vial from the outside world until the moment of injection. A failure at this stage invalidates all downstream results.

Protecting from Contamination and Evaporation

The most immediate function is to provide a secure physical seal. This prevents airborne particles, dust, or other lab contaminants from entering the sample.

Equally important, the seal prevents the evaporation of volatile solvents. Even minor solvent loss can significantly alter the sample concentration, leading to inaccurate quantitative results.

Maintaining Sample Purity and Composition

By creating an isolated environment, the septum preserves the chemical composition of the sample. This ensures that the analysis reflects the true nature of the sample, not a version that has been degraded by environmental exposure.

A Tale of Two Materials: Why PTFE/Silicone Is the Standard

The combination of Polytetrafluoroethylene (PTFE) and silicone is not accidental. Each material is chosen to perform a specific, complementary role that neither could accomplish alone.

The PTFE Layer: The Chemically Inert Shield

The thin layer of PTFE is the only part of the septum that directly contacts the sample. This is by design.

PTFE is prized for its exceptional chemical inertness. It is resistant to nearly all common organic solvents used in HPLC mobile phases and sample diluents. This ensures that nothing from the septum leaches into your sample and appears as an artifact in your chromatogram.

Furthermore, its smooth, non-stick surface minimizes the adherence of sample molecules, reducing the risk of cross-contamination between injections.

The Silicone Layer: The Resilient, Self-Sealing Core

Behind the PTFE shield lies a much thicker layer of silicone rubber. This material provides the mechanical properties of the seal.

Silicone is highly flexible and elastic, allowing it to form a tight seal against the glass rim of the vial. Most importantly, it possesses excellent self-sealing characteristics. When the autosampler needle pierces the septum, the silicone expands back to close the hole, maintaining the seal for subsequent injections.

It also provides good thermal stability (typically up to 200°C), making it suitable for applications that may involve heated sample trays.

Understanding the Practical Implications

The choice of a high-quality septum directly impacts the reliability and efficiency of your entire analytical process, especially in critical applications.

Ensuring Reproducibility and Reliability

By preventing concentration changes and contamination, PTFE/silicone septa are fundamental to achieving reproducible results. This is paramount for method validation, stability studies, and any analysis where precision is key.

Supporting Trace Analyte Analysis

When analyzing compounds at very low concentrations, even minuscule contamination from a low-quality septum can obscure or mimic the analyte peak. The inertness of the PTFE layer is essential for generating a clean baseline and achieving accurate trace-level quantification.

Impact in Regulated Environments

In fields like pharmaceutical research and manufacturing, sample integrity is directly linked to drug safety, efficacy, and quality. Using certified, high-purity septa is a non-negotiable part of ensuring that analytical data is defensible and meets regulatory standards.

Common Pitfalls to Avoid

While effective, septa are not infallible. Proper use is key to avoiding common issues that can compromise your analysis.

Septum Coring and Particulation

If the wrong needle is used or the septum is of poor quality, the needle can punch out a small piece of the septum material. This "core" can fall into the sample, potentially clogging the HPLC system's tubing or column. Always use a needle style recommended for autosamplers, which is typically designed to pierce rather than puncture.

Overtightening Vial Caps

It is a common mistake to overtighten the cap, believing it creates a better seal. This can actually deform the septum, causing it to bulge and preventing it from sealing or resealing properly. Tighten the cap until it is just snug.

The Limits of Reusability

While the self-sealing nature of silicone allows for multiple injections from the same vial, re-using septa for different samples is a high-risk practice. It creates a significant potential for cross-contamination and is not recommended for any quantitative or sensitive analysis. The cost of a new septum is trivial compared to the cost of a failed run or inaccurate result.

Making the Right Choice for Your Goal

Not all analyses have the same requirements. Use your objective to guide your selection and practices.

- If your primary focus is trace-level analysis: Prioritize high-purity septa and never reuse them, as the risk of contamination invalidates the results.

- If your primary focus is high-throughput screening: Ensure the septa are robust enough to handle many rapid, repeated injections without coring or failing.

- If your primary focus is routine QC in a regulated lab: Use certified, lot-traceable septa from a reputable supplier to ensure data defensibility and consistency.

Ultimately, the septum is an active and critical component in your analytical system, not just a simple cap.

Summary Table:

| Function | Material Role | Key Benefit |

|---|---|---|

| Chemical Barrier | PTFE Layer | Inert shield prevents sample leaching and contamination |

| Physical Seal | Silicone Layer | Resilient, self-sealing core for repeated needle injections |

| Contamination Prevention | Combined PTFE/Silicone | Isolates sample from airborne particles and solvents |

| Evaporation Control | Silicone Seal | Maintains sample concentration by preventing solvent loss |

Ensure your HPLC workflows deliver accurate, reliable results with precision-engineered PTFE components from KINTEK.

As detailed in this article, the integrity of your sample is paramount, and the quality of your septa is a critical factor. KINTEK specializes in manufacturing high-purity PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get components that meet the exacting standards required for trace analysis, high-throughput screening, and regulated environments.

Don't let a substandard septum compromise your analytical data. Contact us today to discuss your specific needs and how our PTFE solutions can enhance your application's precision and reliability.

Get a Quote & Discuss Your Needs

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications