At its core, the durability of a PTFE/silicone septum comes from its ability to withstand numerous needle injections without significant wear, coring, or loss of sealing integrity. This physical robustness directly translates into fewer replacements, which minimizes instrument downtime and reduces operational costs, particularly in high-throughput analytical environments.

The true value of a septum is not just its ability to seal a vial, but its ability to do so consistently and inertly over time. The durability of PTFE/silicone septums ensures that the vial's seal is not a variable in your analysis, protecting both your sample and the reliability of your data.

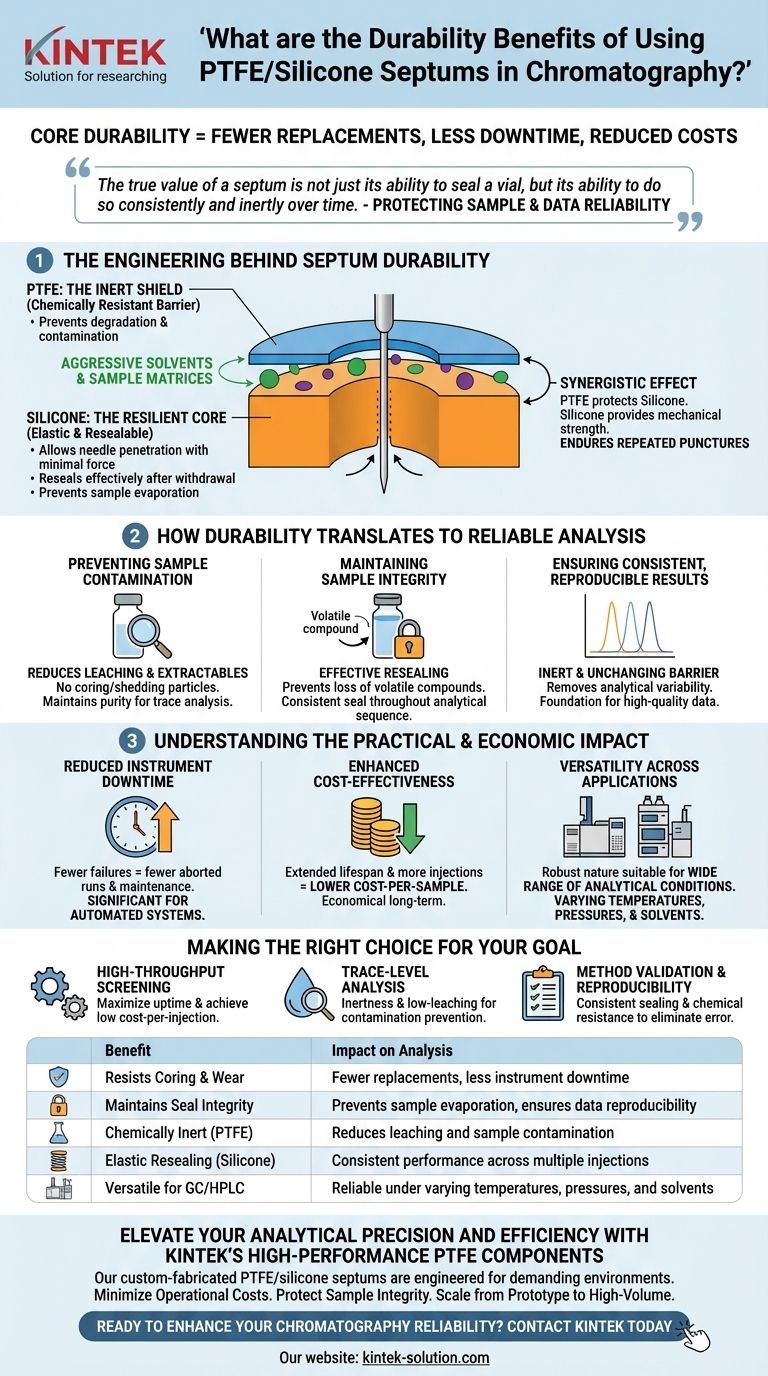

The Engineering Behind Septum Durability

The remarkable durability of these septums is not accidental; it is the result of a synergistic combination of two distinct materials, each chosen for a specific function.

The Role of PTFE: The Inert Shield

Polytetrafluoroethylene (PTFE) serves as the first line of defense. Its primary function is to provide an exceptionally inert barrier between your sample and the main body of the septum.

This chemical resistance is crucial for durability because it prevents aggressive solvents or sample matrices from degrading the septum material over time, ensuring it does not become a source of contamination.

The Function of Silicone: The Resilient Core

Silicone provides the mechanical performance of the septum. It is a highly elastic and resilient polymer that allows a needle to penetrate it with minimal force.

Crucially, after the needle is withdrawn, the silicone's elasticity enables it to reseal effectively, maintaining a secure seal against the vial rim and preventing sample evaporation.

The Synergistic Effect

The two materials work in concert. The thin PTFE layer protects the chemically vulnerable silicone core from the sample, while the silicone provides the mechanical strength and resealability that PTFE alone lacks. This combination allows the septum to endure repeated punctures without failing.

How Durability Translates to Reliable Analysis

A durable septum is more than just a convenience; it is a critical component for ensuring the accuracy and reproducibility of your chromatographic results.

Preventing Sample Contamination

A primary benefit of this durability is the reduction of leaching and extractables. A septum that does not degrade or shed particles (an issue known as coring) ensures that your sample's purity is maintained, which is paramount for sensitive trace analysis.

Maintaining Sample Integrity

Effective resealing after every injection is essential for preventing the loss of volatile compounds. A durable septum guarantees a consistent, reliable seal throughout an entire analytical sequence, even over extended periods.

Ensuring Consistent, Reproducible Results

By providing an inert and unchanging barrier, the septum removes a potential source of analytical variability. This consistency from one injection to the next is the foundation of high-quality, reproducible chromatographic data.

Understanding the Practical and Economic Impact

The physical and chemical properties of PTFE/silicone septums have direct, tangible benefits in a laboratory setting.

Reduced Instrument Downtime

Fewer septum failures mean fewer aborted runs and less time spent on instrument maintenance. For automated systems running long sequences, this reliability is a significant operational advantage.

Enhanced Cost-Effectiveness

While the initial cost may be higher than some alternatives, the extended lifespan and ability to withstand more injections result in a lower cost-per-sample. This makes them a more economical choice in the long run.

Versatility Across Applications

The robust nature of the PTFE/silicone composite makes it suitable for a wide range of analytical conditions. It performs reliably across the varying temperatures, pressures, and solvent types found in both gas chromatography (GC) and high-performance liquid chromatography (HPLC).

Making the Right Choice for Your Goal

Your specific analytical objective should guide your decision-making.

- If your primary focus is high-throughput screening: The durability of PTFE/silicone septums is essential for maximizing uptime and achieving a low cost-per-injection.

- If your primary focus is trace-level analysis: The inertness and low-leaching characteristics are critical for preventing contamination and ensuring data accuracy.

- If your primary focus is method validation and reproducibility: Rely on the consistent sealing and chemical resistance of these septums to eliminate a key source of analytical error.

Ultimately, investing in a durable, high-quality septum is a direct investment in the integrity and reliability of your final results.

Summary Table:

| Benefit | Impact on Analysis |

|---|---|

| Resists Coring & Wear | Fewer replacements, less instrument downtime |

| Maintains Seal Integrity | Prevents sample evaporation, ensures data reproducibility |

| Chemically Inert (PTFE) | Reduces leaching and sample contamination |

| Elastic Resealing (Silicone) | Consistent performance across multiple injections |

| Versatile for GC/HPLC | Reliable under varying temperatures, pressures, and solvents |

Elevate your analytical precision and efficiency with KINTEK's high-performance PTFE components.

Our custom-fabricated PTFE/silicone septums are engineered for the demanding environments of semiconductor, medical, and laboratory industries. By prioritizing precision and durability, we help you:

- Minimize Operational Costs: Reduce septum replacements and instrument downtime.

- Protect Sample Integrity: Ensure contamination-free, reproducible results in trace analysis.

- Scale from Prototype to High-Volume: Get reliable sealing solutions tailored to your specific GC/HPLC workflows.

Ready to enhance your chromatography reliability? Contact KINTEK today to discuss your application and request a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers