The primary advantage of a PTFE bottle's non-stick surface is its ability to prevent materials from adhering to the container walls. This core feature significantly reduces sample loss and cross-contamination while making the bottle exceptionally easy to clean, ensuring the integrity of your work and promoting an efficient, hygienic environment.

The non-stick property of a PTFE bottle is not a simple coating; it is a direct consequence of the material's fundamental chemical inertness. This means the benefit extends far beyond easy cleaning to include unmatched chemical resistance and sample purity, which are critical for sensitive applications.

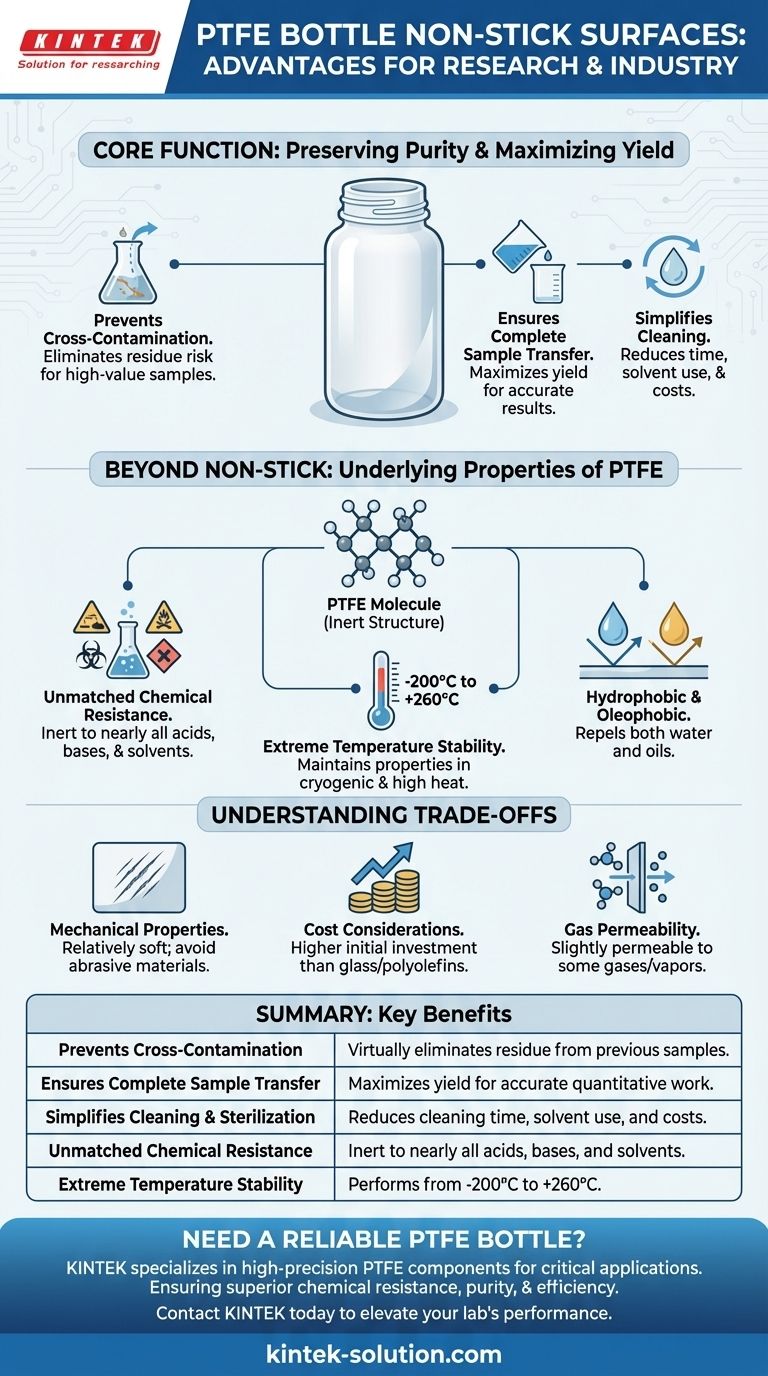

The Core Function: Preserving Purity and Maximizing Yield

A non-stick surface provides practical, measurable benefits in any laboratory or high-purity industrial setting. Its value is tied directly to preventing interaction between the container and its contents.

Preventing Cross-Contamination

Because liquids and solids do not readily stick to PTFE, the risk of a previous sample's residue contaminating the next one is virtually eliminated. This is essential for maintaining the purity of high-value reagents or analytical samples.

Ensuring Complete Sample Transfer

The low surface energy of PTFE allows for complete decanting of liquids and powders. This maximizes yield and is crucial for quantitative work where every microliter or milligram counts for accurate results.

Simplifying Cleaning and Sterilization

PTFE bottles can often be rinsed clean with minimal effort and less aggressive solvents. This reduces cleaning time, lowers solvent consumption and disposal costs, and speeds up workflow between processes.

Beyond Non-Stick: The Underlying Properties of PTFE

The non-stick characteristic is a symptom of PTFE's exceptionally stable molecular structure. Understanding this connection reveals why it is a superior material for demanding tasks.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It resists attack from nearly all acids, bases, solvents, and oxidizing agents, making it the default choice for storing and handling aggressive or corrosive substances.

Extreme Temperature Stability

This material maintains its properties across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). It can be used for applications involving cryogenic materials or high-temperature processes without degrading.

Hydrophobic and Oleophobic Nature

PTFE repels both water (hydrophobic) and oils (oleophobic). This dual resistance is what gives it a uniquely non-stick and non-fouling surface that is difficult for any substance to wet or adhere to.

Understanding the Trade-offs

While powerful, PTFE is not the solution for every single application. Objectivity requires acknowledging its limitations.

Mechanical Properties

Compared to glass or metal, PTFE is a relatively soft material. It can be susceptible to scratching, which can compromise the integrity of the non-stick surface over time if abrasive materials are used.

Cost Considerations

PTFE is a high-performance polymer, and its manufacturing process makes it significantly more expensive than common alternatives like polypropylene (PP), polyethylene (PE), or standard laboratory glass.

Gas Permeability

While excellent as a barrier for liquids, PTFE is slightly permeable to certain gases and vapors. This can be a factor for the long-term storage of highly sensitive, gas-reactive compounds.

Making the Right Choice for Your Application

Selecting the right container material depends entirely on the chemical compatibility, purity requirements, and budget of your specific task.

- If your primary focus is trace analysis or high-purity applications: Choose PTFE to minimize sample adhesion and leaching, which could interfere with results.

- If your primary focus is working with aggressive chemicals: PTFE's unmatched chemical inertness makes it the safest and most reliable option.

- If your primary focus is general-purpose storage of non-reactive substances: A more economical material like glass or polyethylene may be sufficient for your needs.

Ultimately, choosing a PTFE bottle is an investment in reliability, purity, and safety for your most critical applications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Cross-Contamination | Virtually eliminates residue from previous samples. |

| Ensures Complete Sample Transfer | Maximizes yield for accurate quantitative work. |

| Simplifies Cleaning & Sterilization | Reduces cleaning time, solvent use, and costs. |

| Unmatched Chemical Resistance | Inert to nearly all acids, bases, and solvents. |

| Extreme Temperature Stability | Performs from -200°C to +260°C. |

Need a reliable PTFE bottle for your sensitive application?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware like bottles, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your most critical processes benefit from superior chemical resistance, sample purity, and operational efficiency.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact needs.

Contact KINTEK today to discuss your specific requirements and elevate your lab's performance with our precision PTFE products.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the limitations of PTFE/silicone septa regarding temperature? Key Factors for Analytical Integrity

- Why is Teflon used in chemical laboratories? Ensure Ultimate Purity and Chemical Resistance

- What are the primary uses of PTFE stirrers? For Chemically Aggressive & High-Purity Mixing

- What are PTFE silicone septas and their role in the pharmaceutical industry? Ensure Sample Integrity and Accurate Analysis

- Why are PTFE lined vials considered durable? Superior Chemical & Thermal Resistance for Reliable Performance

- How do PTFE silicone septas contribute to cost savings in the pharmaceutical industry? Prevent Costly Failures and Protect Your Bottom Line

- What are the benefits of selecting the appropriate PTFE-coated septum for chromatography? Ensure Accurate & Reproducible Results

- What are some specialized PTFE stirring bars available? Optimize Your Lab Mixing Efficiency