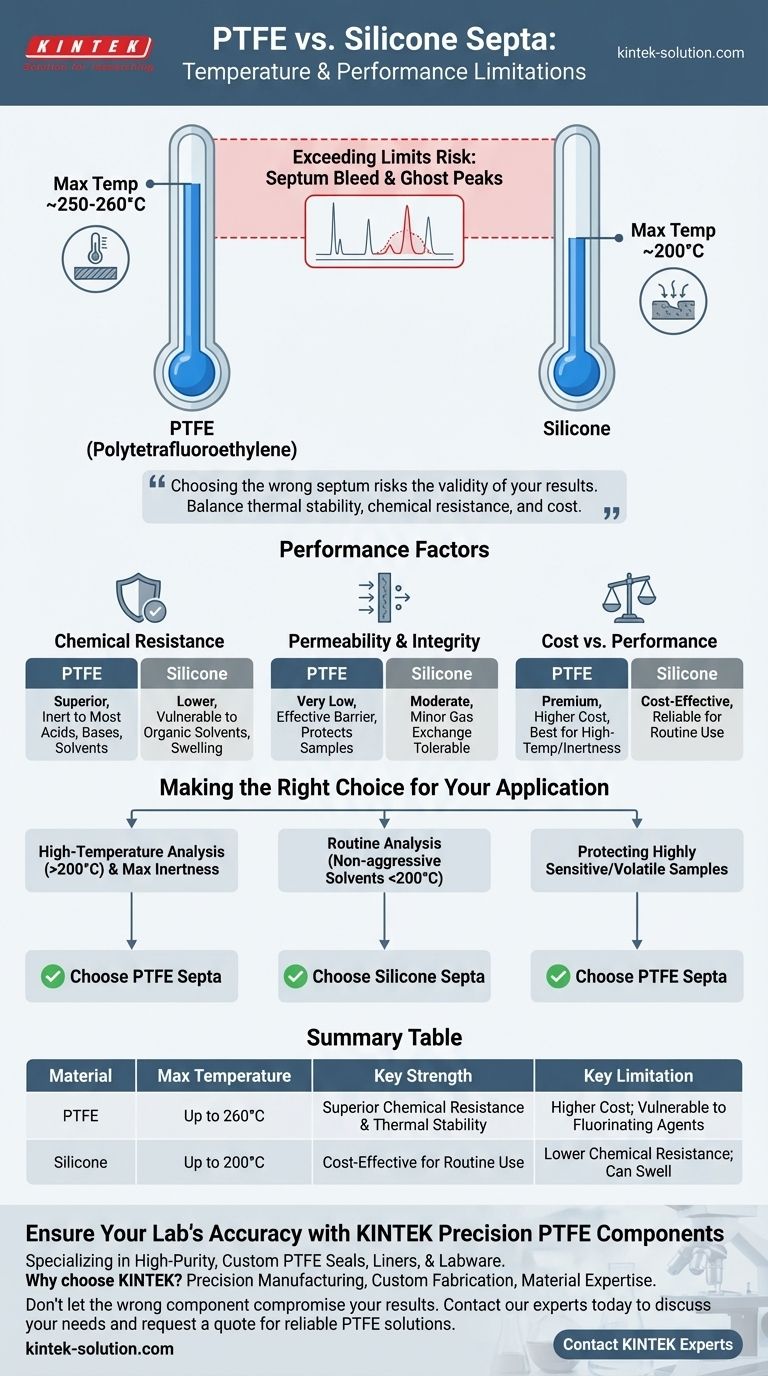

The primary temperature limitation of PTFE/silicone septa lies in their distinct upper operating ranges, which dictates their suitability for specific laboratory procedures. PTFE (polytetrafluoroethylene) can reliably withstand temperatures up to approximately 250-260°C, while standard silicone is limited to around 200°C. Exceeding these thresholds risks material degradation, which can compromise the integrity of your seal and introduce contaminants into your analysis.

While the absolute temperature rating is the most common specification, the true limitation emerges from a trade-off between thermal stability, chemical resistance, and cost. Choosing the wrong septum doesn't just risk failure; it risks the validity of your results.

Deconstructing the Temperature Limits

Understanding what happens at the material level is key to preventing failed analyses. The maximum temperature rating is not a suggestion; it is the point where the material's physical and chemical properties begin to fundamentally change.

PTFE's Thermal Stability

PTFE is a high-performance fluoropolymer, making it the superior choice for high-temperature applications. Its robust structure allows it to maintain its integrity in environments like a heated Gas Chromatography (GC) injection port up to 260°C.

Silicone's Operating Range

Silicone is a versatile and cost-effective elastomer, but it has a lower thermal threshold. Its ceiling of 200°C makes it perfectly suitable for many routine procedures, but it will begin to break down in more demanding, high-temperature analytical conditions.

The Consequences of Exceeding Limits

Pushing a septum beyond its thermal limit causes septum bleed. This is where the material itself begins to degrade and release volatile or semi-volatile compounds. These compounds can appear as ghost peaks in a chromatogram, interfering with your analysis and contaminating your sample and instrument.

Beyond Temperature: Critical Performance Factors

A septum's temperature rating is only one part of the equation. True analytical integrity depends on how the material interacts with your specific sample and method.

Chemical Resistance: The Deciding Factor

PTFE offers exceptional chemical resistance. It is nearly inert to most common acids, bases, and organic solvents, ensuring that the septum does not react with or contaminate your sample.

Silicone, on the other hand, is more susceptible. It can swell, soften, or degrade when exposed to certain organic solvents and strong acids, which can compromise the seal and leach impurities.

Permeability and Sample Integrity

PTFE has very low permeability. This creates an effective barrier against atmospheric gases, preventing your sample from being contaminated by air or moisture over time.

Silicone has moderate permeability. While this makes it unsuitable for long-term storage of sensitive samples, it can be acceptable for applications like headspace sampling where some minor gas exchange is tolerable.

Understanding the Trade-offs

Choosing the right septum requires balancing performance requirements with practical constraints. No single material is perfect for every situation.

Performance vs. Cost

There is a clear hierarchy. PTFE is the premium material, offering superior temperature and chemical performance at a higher cost. Silicone provides a reliable, cost-effective solution for less demanding, routine applications where its limitations are not a concern.

Specific Chemical Vulnerabilities

Even the robust nature of PTFE has its limits. It is known to be vulnerable to attack from highly reactive chemicals like elementary fluorine, chlorine trifluoride, and other exotic fluorinating agents, especially at high temperatures and pressures.

Making the Right Choice for Your Application

Selecting the correct septum is a critical control point for ensuring data quality. Use your specific analytical goal as your guide.

- If your primary focus is high-temperature analysis (>200°C) and maximum chemical inertness: Choose PTFE septa to ensure thermal stability and prevent sample contamination.

- If your primary focus is routine analysis with non-aggressive solvents below 200°C: Silicone septa offer a reliable and highly cost-effective solution.

- If your primary focus is protecting highly sensitive or volatile samples: The low permeability and superior chemical resistance of PTFE provide the most secure seal.

Ultimately, selecting the correct septum is a foundational step in guaranteeing the accuracy and reliability of your analytical results.

Summary Table:

| Material | Max Temperature | Key Strength | Key Limitation |

|---|---|---|---|

| PTFE | Up to 260°C | Superior chemical resistance & thermal stability | Higher cost; vulnerable to exotic fluorinating agents |

| Silicone | Up to 200°C | Cost-effective for routine use | Lower chemical resistance; can swell with solvents |

Ensure Your Lab's Accuracy with Precision PTFE Components

Choosing the right septum is critical for protecting your samples and instruments. At KINTEK, we specialize in manufacturing high-purity, custom PTFE components—including seals, liners, and labware—that deliver the superior temperature resistance and chemical inertness demanded by semiconductor, medical, and laboratory applications.

Why choose KINTEK?

- Precision Manufacturing: Our components are engineered to perform reliably at high temperatures, preventing septum bleed and contamination.

- Custom Fabrication: We work with you from prototype to high-volume production to meet your exact specifications.

- Material Expertise: We understand the trade-offs between performance and cost, helping you select the optimal solution for your analytical integrity.

Don't let the wrong component compromise your results. Contact our experts today to discuss your specific needs and request a quote for reliable PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main benefits of PTFE filters? Achieve Unmatched Chemical Resistance and Purity

- What are PTFE ferromagnetic support discs composed of? A Dual-Material Design for Superior Grinding & Polishing

- Which chemicals are fully compatible with PTFE filters? Discover Unmatched Chemical Resistance

- What are the benefits of using high-performance materials in chemical laboratories? Ensure Purity and Reliability

- What types of PTFE-lined bottle caps are available? Find the Perfect Seal for Your Application

- What overall role do PTFE/silicone septa play in HPLC workflows? Protect Sample Integrity for Accurate Results

- In what types of laboratory equipment are Teflon membranes commonly used? Ensuring Purity in Demanding Applications

- What are PTFE silicone septa and what are they composed of? The Key to Reliable Chromatography Seals