The single most important reason Teflon is ubiquitous in chemical laboratories is its profound chemical inertness. Its technical name, Polytetrafluoroethylene (PTFE), describes a molecule that is almost completely non-reactive. This unique stability ensures that lab equipment made from Teflon will not interfere with, contaminate, or be degraded by the vast majority of chemicals it contains.

The core challenge in any chemical experiment is isolating and observing a specific reaction. Teflon solves this by being a virtually invisible participant—it provides a stable, non-contaminating, and durable environment that allows the chemicals themselves to be the sole actors.

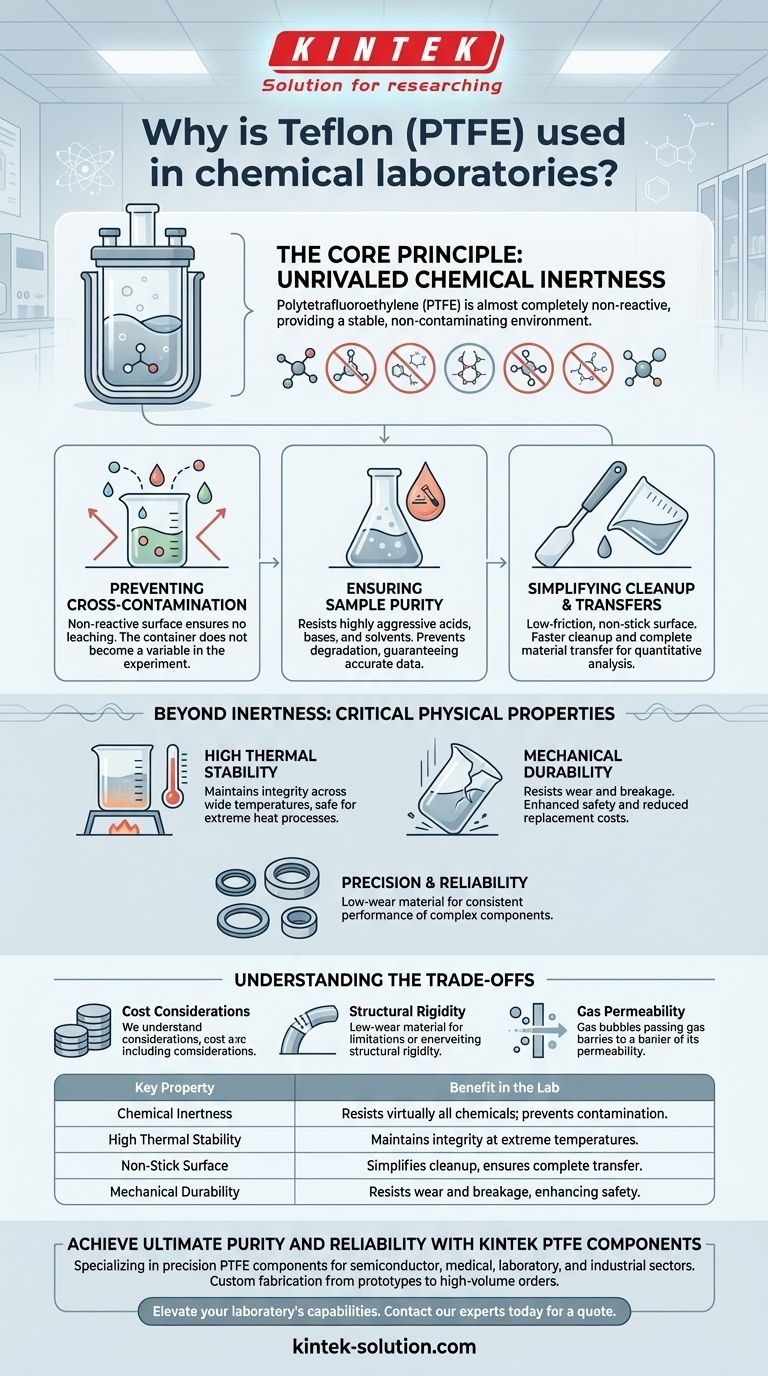

The Core Principle: Unrivaled Chemical Inertness

The primary value of Teflon stems from its chemical stability, which directly translates into more reliable and safer scientific work. This single property prevents a host of common laboratory problems.

Preventing Cross-Contamination

When working with sensitive reactions, even microscopic traces of a foreign substance can invalidate results. Teflon’s non-reactive surface ensures that no material from the container leaches into the chemical mixture.

This prevents the container itself from becoming an unwanted variable in the experiment.

Ensuring Sample Purity

Unlike metal or even certain types of glass, Teflon does not corrode or degrade when exposed to highly aggressive acids, bases, or solvents. This guarantees that the sample remains pure and the experimental data is accurate.

The integrity of the equipment is directly linked to the integrity of the results.

Simplifying Cleanup and Transfers

Teflon is famously non-stick. This low-friction surface prevents chemicals, especially viscous liquids or sticky precipitates, from adhering to beakers and spatulas.

This property not only makes cleanup faster but also ensures a more complete transfer of materials from one container to another, which is critical for quantitative analysis.

Beyond Inertness: Critical Physical Properties

While chemical resistance is its headline feature, Teflon's physical characteristics make it uniquely suited for the demanding lab environment.

High Thermal Stability

Many chemical reactions require heating or produce significant heat. Teflon maintains its structural integrity and chemical inertness across a wide range of temperatures, making it safe for use in processes involving extreme heat.

Mechanical Durability

Lab equipment must be robust. Teflon provides excellent resistance to wear and mechanical stress. Unlike brittle glassware, Teflon labware will not shatter if dropped, enhancing safety and reducing replacement costs.

Precision and Reliability

For components like seals, gaskets, and bushings in lab equipment, Teflon provides a reliable, low-wear material. This ensures that complex apparatuses perform consistently over long periods with minimal maintenance.

Understanding the Trade-offs

No material is perfect for every application. Being an effective advisor means acknowledging limitations and helping users make informed choices.

Cost Considerations

Teflon is generally a more expensive material than standard laboratory glass or other plastics like polypropylene. The initial investment in Teflon labware is higher, though its longevity can offset this over time.

Structural Rigidity

While durable, Teflon is a relatively soft material and is not as rigid as glass or metal. It can deform under high loads or pressures, making it unsuitable for certain high-pressure applications without reinforcement.

Gas Permeability

Teflon is not completely impermeable to certain small gas molecules. For high-vacuum systems or experiments highly sensitive to atmospheric gases over long durations, this slight permeability might be a factor to consider.

Making the Right Choice for Your Goal

Selecting the correct lab material is a crucial decision based on the specific demands of your work.

- If your primary focus is handling highly corrosive reagents: Teflon is the default choice for safety and to prevent equipment degradation.

- If your primary focus is trace analysis or ultimate purity: Teflon's non-leaching, non-reactive surface is essential to prevent contamination that could skew sensitive results.

- If your primary focus is durability and long-term value: Teflon's resistance to breakage and chemical attack makes it a safer and often more cost-effective investment than fragile alternatives.

Ultimately, selecting Teflon is a strategic decision to remove the container as a variable, ensuring your focus remains squarely on the chemistry.

Summary Table:

| Key Property | Benefit in the Lab |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents contamination. |

| High Thermal Stability | Maintains integrity and performance at extreme temperatures. |

| Non-Stick Surface | Simplifies cleanup and ensures complete material transfer. |

| Mechanical Durability | Resists wear and breakage, enhancing safety and longevity. |

Achieve Ultimate Purity and Reliability with KINTEK PTFE Components

When your experiments demand the highest level of chemical resistance and sample integrity, the material of your labware is critical. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand that your work cannot tolerate contamination or equipment failure. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact PTFE solution your application requires.

Elevate your laboratory's capabilities. Contact our experts today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability