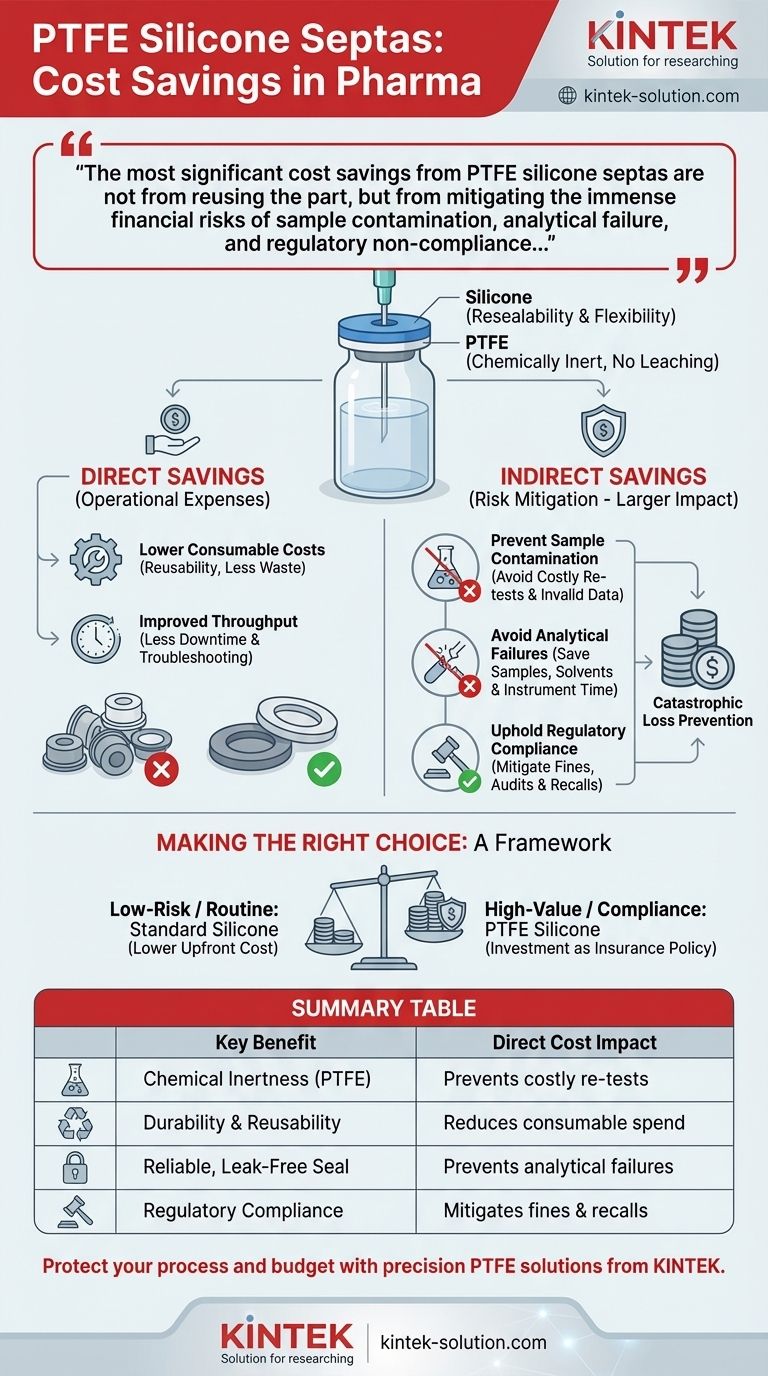

At first glance, PTFE silicone septas contribute to cost savings in the pharmaceutical industry through their durability and reusability, which directly lowers the budget for consumable lab supplies. More importantly, however, their true economic value lies in their ability to prevent catastrophic financial losses by ensuring the integrity of high-stakes analytical processes, where a single failure can cost far more than the component itself.

The most significant cost savings from PTFE silicone septas are not from reusing the part, but from mitigating the immense financial risks of sample contamination, analytical failure, and regulatory non-compliance that are inherent in pharmaceutical development and quality control.

The Critical Role of Septas in Pharmaceutical Integrity

A septum is a small but essential closure, typically used in vials for analytical instruments like high-performance liquid chromatography (HPLC) or gas chromatography-mass spectrometry (GC-MS). Its job is to create a perfect seal that protects the sample from contamination while allowing a needle to pierce it for sample extraction.

Why the PTFE and Silicone Combination Matters

PTFE silicone septas are a composite material, engineered to provide the benefits of two distinct polymers. The silicone layer provides excellent resealability and flexibility, ensuring the vial remains sealed after being pierced by a needle.

The thin layer of PTFE (polytetrafluoroethylene) that faces the sample is the key. PTFE is almost universally chemically inert, meaning it will not react with or leach into the drug formulation or solvent inside the vial.

Ensuring Precision and Reliability

In pharmaceutical analysis, precision is not optional; it is a regulatory requirement. The reliable, leak-free seal created by a well-manufactured PTFE silicone septum is fundamental to achieving accurate and repeatable results. This prevents sample evaporation and protects it from atmospheric contamination, both of which would invalidate the analysis.

The Direct Path to Cost Savings: Reducing Material Spend

The most obvious cost benefit comes from the physical characteristics of the septa themselves, which reduce direct operational expenses.

Lowering Consumable Costs Through Reusability

Unlike cheaper, single-use alternatives, high-quality PTFE silicone septas are durable enough to be reused for certain applications. This directly reduces the frequency of repurchasing and lowers the overall volume of consumable waste, contributing to a smaller operational budget.

Improving Throughput with Less Downtime

Because they are more durable and provide a more reliable seal, these septas reduce the time spent on troubleshooting leaky vials or replacing failed components. In a high-throughput lab, this translates to more analyses run per day and better use of expensive analytical equipment.

The Indirect (and Larger) Savings: Mitigating Financial Risk

The most profound cost savings are realized by preventing expensive failures. In the pharmaceutical world, the cost of a failed component is rarely just the cost of the component itself.

Preventing Sample Contamination

A contaminated sample leads to invalid analytical data. This forces researchers to run expensive and time-consuming re-tests. Worse, if contamination is not caught, it could lead to incorrect conclusions about a drug's stability or purity, jeopardizing an entire development program. The inertness of the PTFE layer is a critical safeguard against this risk.

Avoiding Costly Analytical Failures

Techniques like GC-MS and HPLC rely on precise, minute sample volumes. A leaky septum can cause sample loss or solvent evaporation, altering the concentration and ruining the entire analytical run. This wastes not only the sample but also expensive solvents, standards, and valuable instrument time.

Upholding Regulatory Compliance

The pharmaceutical industry operates under strict oversight from bodies like the FDA. Analytical results must be defensible and meet stringent legal standards. Using high-integrity components like PTFE silicone septas is part of ensuring that processes are compliant. A failed audit or product recall due to faulty data can result in astronomical fines and reputational damage, dwarfing any savings from cheaper components.

Understanding the Trade-offs

While PTFE silicone septas offer significant advantages, they are not the only option, and their value is context-dependent.

The Upfront Cost Consideration

Septas with a PTFE layer are generally more expensive than those made of pure silicone. This higher initial price can be a factor for labs with extremely tight budgets for routine, non-critical tasks.

When Simpler Septas Suffice

For routine procedures where samples are not aggressive or highly sensitive, a standard silicone septum can be a cost-effective and perfectly practical choice. The key is understanding the chemical compatibility required for the application.

The Value as an Insurance Policy

The higher cost of a PTFE silicone septum should be viewed as an investment in risk mitigation. For high-value drug candidates, final product quality control, or any analysis involving reactive chemicals, the superior performance is not a luxury—it is a necessary insurance policy against failure.

Making the Right Choice for Your Goal

Ultimately, the decision rests on a clear understanding of the application and its associated risks.

- If your primary focus is minimizing upfront consumable costs for low-risk, routine screening: Standard silicone septa may offer sufficient performance and a lower purchase price.

- If your primary focus is ensuring the absolute integrity of high-value samples and meeting regulatory standards: The investment in PTFE silicone septas provides critical long-term savings by preventing catastrophic analytical and compliance failures.

- If your primary focus is maximizing throughput in a busy analytical lab: The durability and reliability of PTFE silicone septas reduce instrument downtime and troubleshooting, making them the more efficient choice.

Choosing the right component requires looking beyond the sticker price to understand its total impact on your operational integrity and financial risk.

Summary Table:

| Key Benefit | Direct Cost Impact |

|---|---|

| Chemical Inertness (PTFE Layer) | Prevents sample contamination, avoiding costly re-tests and invalid data. |

| Durability & Reusability | Reduces consumable spend and waste versus single-use alternatives. |

| Reliable, Leak-Free Seal | Prevents analytical failures, saving expensive solvents, standards, and instrument time. |

| Regulatory Compliance | Mitigates risk of fines, failed audits, and product recalls. |

Protect your pharmaceutical processes and your budget with precision-engineered PTFE components from KINTEK.

High-quality PTFE silicone septas are a critical investment in risk mitigation for semiconductor, medical, laboratory, and industrial applications. KINTEK specializes in manufacturing reliable PTFE components—including seals, liners, and custom labware—that prioritize precision and performance.

Whether you need prototypes or high-volume orders, our custom fabrication ensures you get the exact components you need to safeguard your high-stakes analytical work.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can enhance your operational integrity and drive long-term cost savings.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do PTFE and silicone septa compare in terms of temperature range? Choosing the Right Septa for Your Lab

- What is the significance of temperature stability in PTFE lined vials? Ensure Reliable Performance in Extreme Conditions

- What sizes and pore options are available for PTFE filters? Choose the Right Filter for Your Application

- What makes PTFE lined vials easy to clean? The Science Behind Their Non-Stick, Inert Surface

- What is the significance of PTFE shovels being autoclavable? Ensuring Absolute Sterility for Sensitive Processes

- What are PTFE lined caps made of? A Guide to Their Inert, Protective Construction

- In what ways are PTFE silicone septas versatile for pharmaceutical applications? Ensuring Sample Integrity from Discovery to QC

- How should new PTFE stopcock plugs be cleaned and prepared for use? Ensure a Perfect, Leak-Free Seal