Selecting the appropriate PTFE-coated septum is a foundational decision that directly impacts the integrity of your chromatographic results. Choosing correctly improves the accuracy, reproducibility, and overall efficiency of your analysis. It ensures chemical compatibility and temperature stability while providing the physical durability needed to maintain a perfect seal, preventing sample contamination and instrument downtime.

The choice of a septum is not merely about sealing a vial; it's about creating an inert chemical barrier that protects sample integrity from the moment of injection through the entire analytical process, ensuring your results are both accurate and trustworthy.

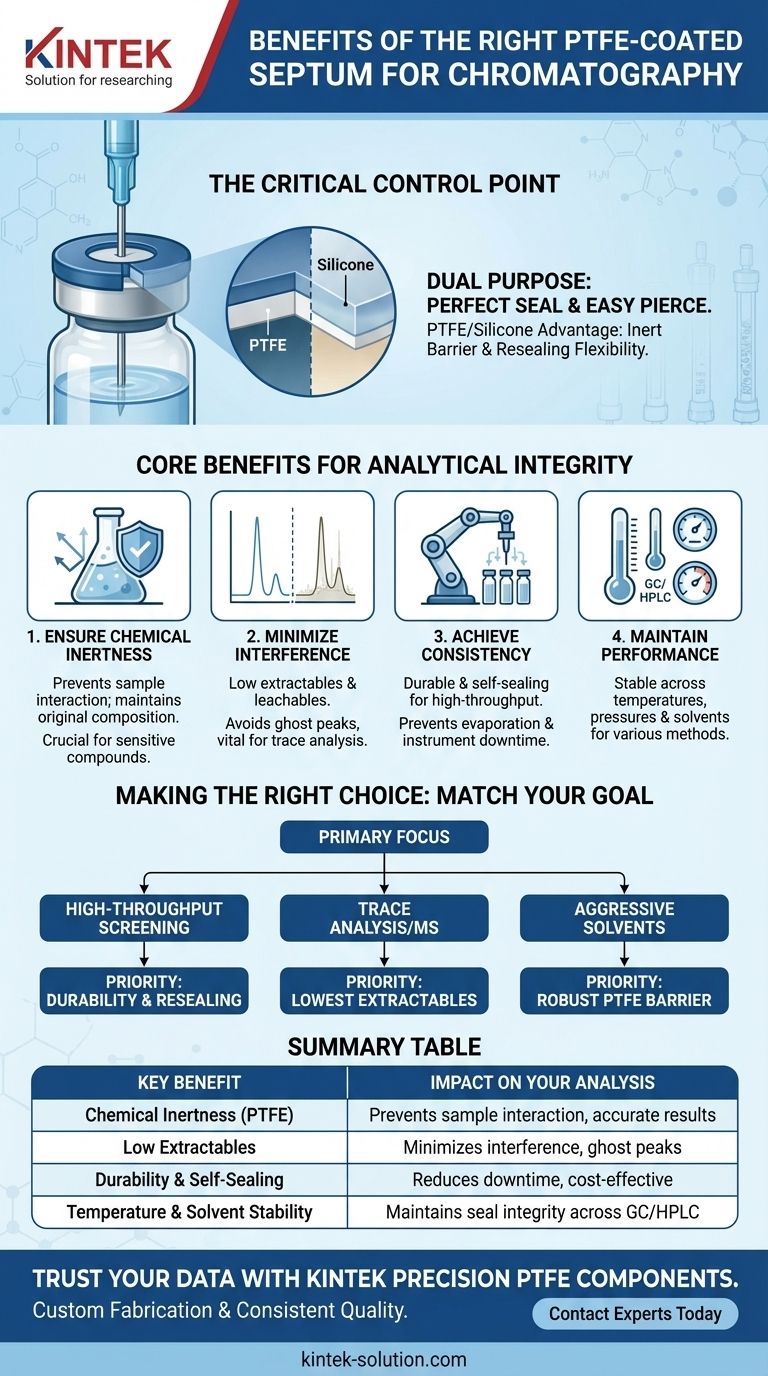

Why the Septum is a Critical Control Point

A vial septum serves a dual purpose: it must maintain a perfect seal to prevent sample evaporation and contamination, yet it must also be easily pierced by an autosampler needle. The material must then reseal itself perfectly after the needle is withdrawn.

The PTFE/Silicone Advantage

The most effective septa combine two materials: Polytetrafluoroethylene (PTFE) and silicone. The PTFE side faces the sample, providing an exceptionally inert chemical barrier. The silicone side provides the physical flexibility and resealing capability needed to withstand needle puncture.

Core Benefits of a High-Quality PTFE Septum

A well-chosen septum provides a series of cascading benefits that safeguard the quality of your analytical data from start to finish.

Ensuring Uncompromised Sample Integrity

The chemical inertness of PTFE is its most critical feature. It prevents any interaction between the septum material and your sample, which is crucial for maintaining the original composition of your analyte.

This barrier function is non-negotiable for achieving consistent and reproducible results, especially when working with sensitive or reactive compounds.

Minimizing Analytical Interference

Low-quality septa can release contaminants—known as extractables and leachables—into your sample upon solvent contact or needle puncture.

These contaminants can introduce ghost peaks or interfere with the detection of your target compounds. A high-quality PTFE/silicone septum is specifically designed to minimize this risk, which is vital for trace analysis where sample purity is paramount.

Achieving Consistency Across Multiple Injections

The septum's durability and self-sealing capability determine its performance in high-throughput environments. The silicone layer provides the robustness to withstand repeated punctures without fragmenting or failing.

This resilience prevents sample loss from evaporation, minimizes instrument downtime from failed seals, and ultimately improves the cost-effectiveness of your laboratory operations.

Maintaining Performance Under Demanding Conditions

The combination of PTFE and silicone creates a septum with outstanding versatility. It can withstand the wide range of temperatures, pressures, and solvent types used in both gas chromatography (GC) and high-performance liquid chromatography (HPLC).

This stability ensures that the septum maintains its seal integrity regardless of the specific analytical method being employed.

Understanding the Trade-offs and Common Pitfalls

While PTFE/silicone is the gold standard, not all septa are created equal. The context of your analysis dictates the specific properties you must prioritize.

Matching the Septum to Your Technique

The demands of your specific application should guide your selection. For gas chromatography (GC), preventing sample evaporation is a primary concern, requiring a septum with excellent resealing properties.

For ultra-sensitive techniques like mass spectrometry, a septum with the lowest possible extractables is required to avoid interference and ensure a clean baseline.

The Importance of Vial and Needle Compatibility

A perfect seal can only be achieved if the septum is correctly matched to the vial and cap. An improperly sized septum can lead to leaks, evaporation, or contamination.

Furthermore, using the correct autosampler needle type is important. A sharp, non-coring needle will pierce the septum cleanly, extending its life and preventing small fragments from falling into your sample.

Recognizing Quality Manufacturing

High-quality manufacturing standards are essential for consistent performance. A reliable manufacturer ensures that the PTFE layer is uniform and properly bonded to the silicone, guaranteeing a consistent and reliable barrier in every vial.

Making the Right Choice for Your Goal

Your primary analytical objective should be the deciding factor in your selection process.

- If your primary focus is high-throughput screening: Prioritize a septum known for its exceptional durability and resealing capabilities to withstand hundreds of injections without failure.

- If your primary focus is trace analysis or mass spectrometry: Select a septum certified for low extractables and leachables to ensure minimal background interference and maximum signal-to-noise.

- If your primary focus is working with aggressive solvents: Ensure the PTFE barrier is robust and compatible with your specific chemical matrix to prevent degradation and sample contamination.

Ultimately, a well-chosen septum acts as a silent guardian of your data, enabling you to trust your results with confidence.

Summary Table:

| Key Benefit | Impact on Your Analysis |

|---|---|

| Chemical Inertness (PTFE) | Prevents sample interaction, ensuring accurate and reproducible results. |

| Low Extractables | Minimizes background interference and ghost peaks, crucial for trace analysis. |

| Durability & Self-Sealing | Withstands repeated punctures, reducing downtime and cost in high-throughput labs. |

| Temperature & Solvent Stability | Maintains seal integrity across a wide range of GC and HPLC methods. |

Trust Your Data with KINTEK Precision PTFE Components

The right septum is a critical control point for analytical integrity. At KINTEK, we specialize in manufacturing high-performance PTFE components, including septa, seals, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

We understand that your success depends on uncompromised sample integrity and instrument reliability. Our PTFE-coated septa are engineered for superior chemical resistance, low extractables, and exceptional durability to meet the rigorous demands of your chromatography applications.

Let us provide the precision you need:

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

- Consistent Quality: Rigorous manufacturing ensures every component delivers reliable performance.

Elevate your analytical confidence. Contact our experts today to discuss your specific requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech